2025 Guide: How to Choose the Right Filling Machine for Your Business

In the fast-evolving landscape of manufacturing, selecting the right equipment plays a crucial role in the efficiency and growth of your business. Among the various types of machinery available, the filling machine stands out as a vital component in the production line, particularly for industries dealing with liquids, granules, or powders. As businesses strive for optimal performance and profitability, understanding the diverse options and functionalities of filling machines becomes essential.

Choosing the right filling machine requires careful consideration of various factors, including product type, production volume, and the level of automation desired. With an array of designs, sizes, and technologies on the market, making an informed decision can be daunting. This guide aims to simplify the selection process by highlighting key aspects to consider, ensuring that you find the filling machine that aligns perfectly with your business needs. Ultimately, the right choice will not only enhance operational efficiency but also contribute to the overall success of your enterprise.

Understanding Different Types of Filling Machines Available on the Market

When selecting a filling machine for your business, it is essential to understand the variety of types available on the market. The most common categories include liquid filling machines, powder filling machines, and paste filling machines. Each type is designed to handle specific materials and packaging needs. Liquid filling machines are typically used for beverages, oils, and other liquids, offering options such as gravity, pressure, and vacuum filling methods to ensure precision and efficiency. On the other hand, powder filling machines cater to dry products like spices, flour, and detergents, utilizing auger or volmetric systems for accurate measurements.

Another important category is paste filling machines, which are ideal for thicker substances such as sauces, creams, and gels. These machines are often equipped with pumps or piston fillers to manage the viscosity of the material effectively. Additionally, businesses must consider the automation level of the filling machines, ranging from manual to fully automated systems, which can significantly impact production efficiency and labor costs. Understanding these distinctions will help you choose the right filling machine that fits your specific production requirements, ultimately leading to improved operational efficiency and product quality.

Key Factors to Consider When Choosing a Filling Machine for Your Business

When selecting the right filling machine for your business, several key factors must be considered to ensure optimal efficiency and productivity. Firstly, understanding the type of product being filled is crucial. Different substances, whether liquids, powders, or granules, require specific filling technologies to maintain consistency and accuracy. For instance, viscous liquids may need a different approach compared to dry powders, which can affect the choice of machine design and functionality.

Another significant factor is the production capacity and speed of the filling machine. Businesses must assess their output requirements to determine the appropriate machine size and speed settings that align with their production goals. It is essential to balance between achieving high output rates and maintaining quality standards, as machines that operate too quickly may sacrifice precision. Additionally, the ease of cleaning and maintenance should be a priority, as machines requiring frequent downtime for cleaning can negatively impact overall productivity and lead to increased operational costs.

Lastly, consider the machine's adaptability and ease of integration into existing production lines. A filling machine that can accommodate fluctuations in product types or packaging sizes will provide greater flexibility as market demands shift. Evaluating the machine’s compatibility with current systems, as well as its potential for future upgrades, can be instrumental in making a choice that supports both immediate needs and long-term growth.

2025 Guide: How to Choose the Right Filling Machine for Your Business

| Filling Machine Type |

Production Speed (Bottles/Minute) |

Filling Accuracy (%) |

Product Compatibility |

Cost Range ($) |

| Piston Filler |

30-100 |

±1% |

Viscous Liquids |

5,000 - 25,000 |

| Gravity Filler |

20-60 |

±0.5% |

Thin Liquids |

3,000 - 15,000 |

| Pump Filler |

40-120 |

±1% |

Liquid Foods |

4,000 - 20,000 |

| Aseptic Filler |

60-180 |

±0.2% |

Dairy Products |

20,000 - 100,000 |

| Vacuum Filler |

10-50 |

±1.5% |

Semi-Solid Foods |

2,000 - 10,000 |

Evaluating Your Production Capacity and Industry Requirements

When selecting the right filling machine for your business, it’s crucial to evaluate your production capacity and industry requirements. Understanding your production capacity involves assessing the volume of products you need to fill within a specific timeframe. This could vary greatly depending on whether you are a startup or an established company scaling operations. A good first step is to calculate your daily output needs and consider whether you foresee any growth in demand. This will help you choose a machine that not only meets your current needs but can also accommodate future growth.

Tips: Always consider the maintenance and operational costs associated with each filling machine. A cheaper initial investment might result in higher long-term costs due to repairs and inefficiencies. Look for machines that have a good track record of reliability to ensure smooth production.

Industry requirements also play a vital role in your choice of filling equipment. Different industries have specific standards for filling processes, such as food safety regulations or pharmaceutical compliance. It's essential to select machinery that not only complies with these standards but also fits seamlessly into your existing production line. Understanding the unique challenges of your industry will help you narrow down the best options available, ensuring you invest in a filling machine that supports your operational goals efficiently.

Tips: Engage with industry peers or attend trade shows to gain insights into the latest technologies and standards. Networking can provide invaluable information that shapes your decision-making process.

2025 Guide: How to Choose the Right Filling Machine for Your Business

This chart illustrates the distribution of businesses based on their required filling machine capacity as of 2025. The data signifies varying needs across different production scales, highlighting the importance of selecting the appropriate filling machine for optimal efficiency.

Budgeting for Your Filling Machine: Costs and Investment Considerations

When budgeting for a filling machine, it is essential to consider not only the initial purchase price but also the total cost of ownership over time. Factors such as installation, maintenance, and operational efficiency play significant roles in determining the long-term investment. For instance, a machine that is slightly more expensive upfront may save money in maintenance and downtime, ultimately proving to be the more economical choice.

Additionally, businesses must account for the specific needs of their product lines and production volumes. Higher-capacity machines might have a bigger price tag but could increase production speed and efficiency, leading to greater output and profitability. On the other hand, smaller operations may find that manual or semi-automated machines suffice, thus providing a lower-cost entry point without sacrificing quality. Thoroughly assessing these aspects will lead to a more informed decision that aligns with both current budget constraints and future growth expectations.

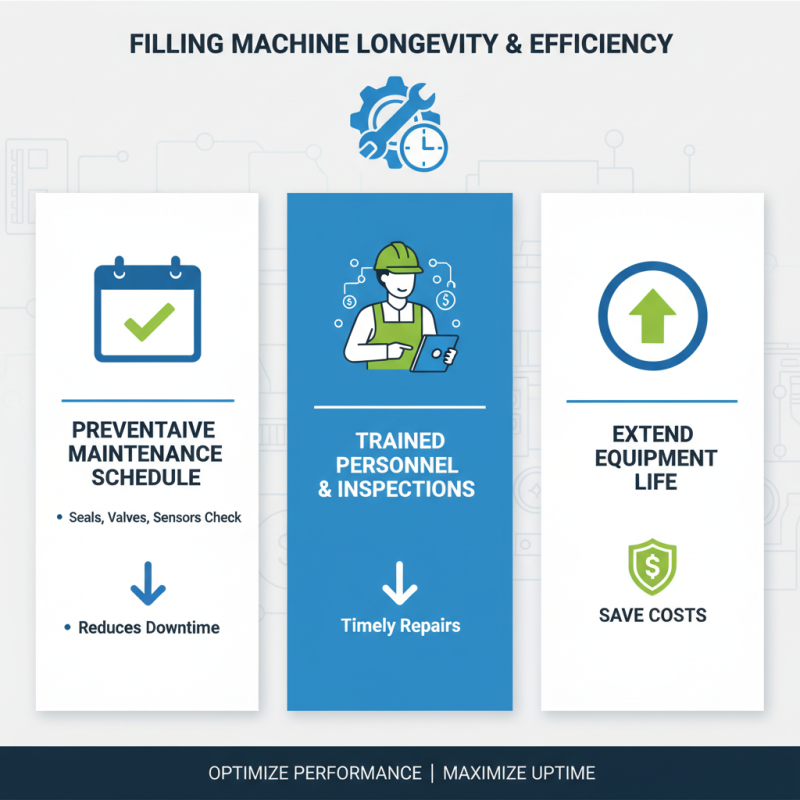

Maintenance and Support: Ensuring Longevity of Your Filling Equipment

When investing in a filling machine, understanding the importance of maintenance and support is crucial for ensuring the longevity and efficiency of your equipment. Regular maintenance not only extends the life of your filling machine but also helps prevent costly downtimes and production halts. Creating a maintenance schedule tailored to your machine’s specific requirements, including routine checks on seals, valves, and sensors, can significantly enhance performance. Trained personnel should conduct inspections and make timely repairs to minimize wear and tear.

Moreover, having a reliable support system in place is essential for troubleshooting and solving potential issues swiftly. Building a relationship with your equipment supplier can provide access to technical support, ensuring that assistance is available when needed. Additionally, investing in training for your staff on proper operational techniques and maintenance can reduce errors and improve overall efficiency. A well-maintained filling machine not only boosts productivity but also contributes to the consistency and quality of your products, vital for customer satisfaction and business growth.