2025 Insights: 7 Reasons Why the Best Industrial Servo Motor is Your Smartest Investment

The rapid evolution of industrial automation and robotics has made the selection of an Industrial Servo Motor a crucial consideration for manufacturers aiming to optimize performance and efficiency.

According to a recent report by Fortune Business Insights, the global industrial servo motor market is expected to grow from USD 6.78 billion in 2021 to USD 12.01 billion by 2028, demonstrating a CAGR of 8.5%. This staggering growth underscores the increasing reliance on these high-precision motors across various sectors, including automotive, aerospace, and manufacturing.

The integration of advanced features, such as real-time feedback and enhanced reliability, positions the Industrial Servo Motor not only as a pivotal component in automated systems but also as a smart investment for organizations looking to enhance productivity and reduce operational costs.

In this blog, we will explore seven compelling reasons why investing in the best Industrial Servo Motor is essential for future-proofing your operations and driving competitive advantage.

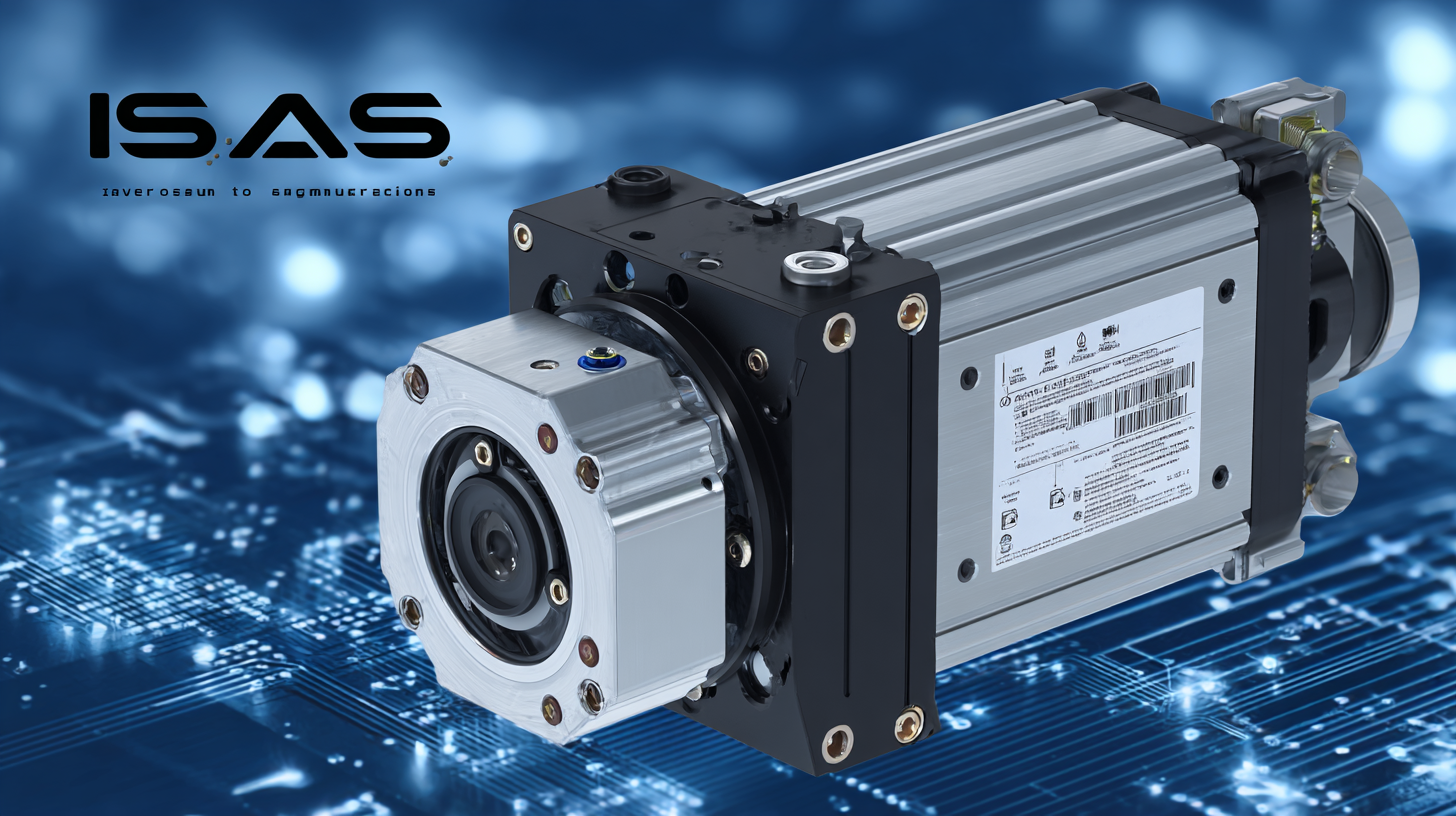

Understanding Industrial Servo Motors: Types and Applications

Industrial servo motors are pivotal in modern manufacturing processes, offering precision and reliability that traditional motors cannot match. These motors come in various types, primarily AC and DC, each suited for specific applications depending on electrical requirements and performance. For low-voltage applications, DC servo motors are often preferred due to their excellent response and control characteristics, making them ideal for robotics and automated systems. Conversely, AC servo motors are favored in high-powered settings, such as aerospace and automotive manufacturing, due to their durability and efficiency over longer operational periods.

The versatility of industrial servo motors extends into multiple sectors, where they are critical for ensuring high performance and accuracy. In robotics, servo motors are utilized for precise movements, enabling complex tasks to be performed with minimal error. In the automotive industry, they drive assembly lines, enhancing production efficiency and product quality. Understanding the types and applications of servo motors is essential for businesses looking to invest in cutting-edge technology that not only meets current demands but also supports future growth and innovation.

2025 Insights: Benefits of Investing in Industrial Servo Motors

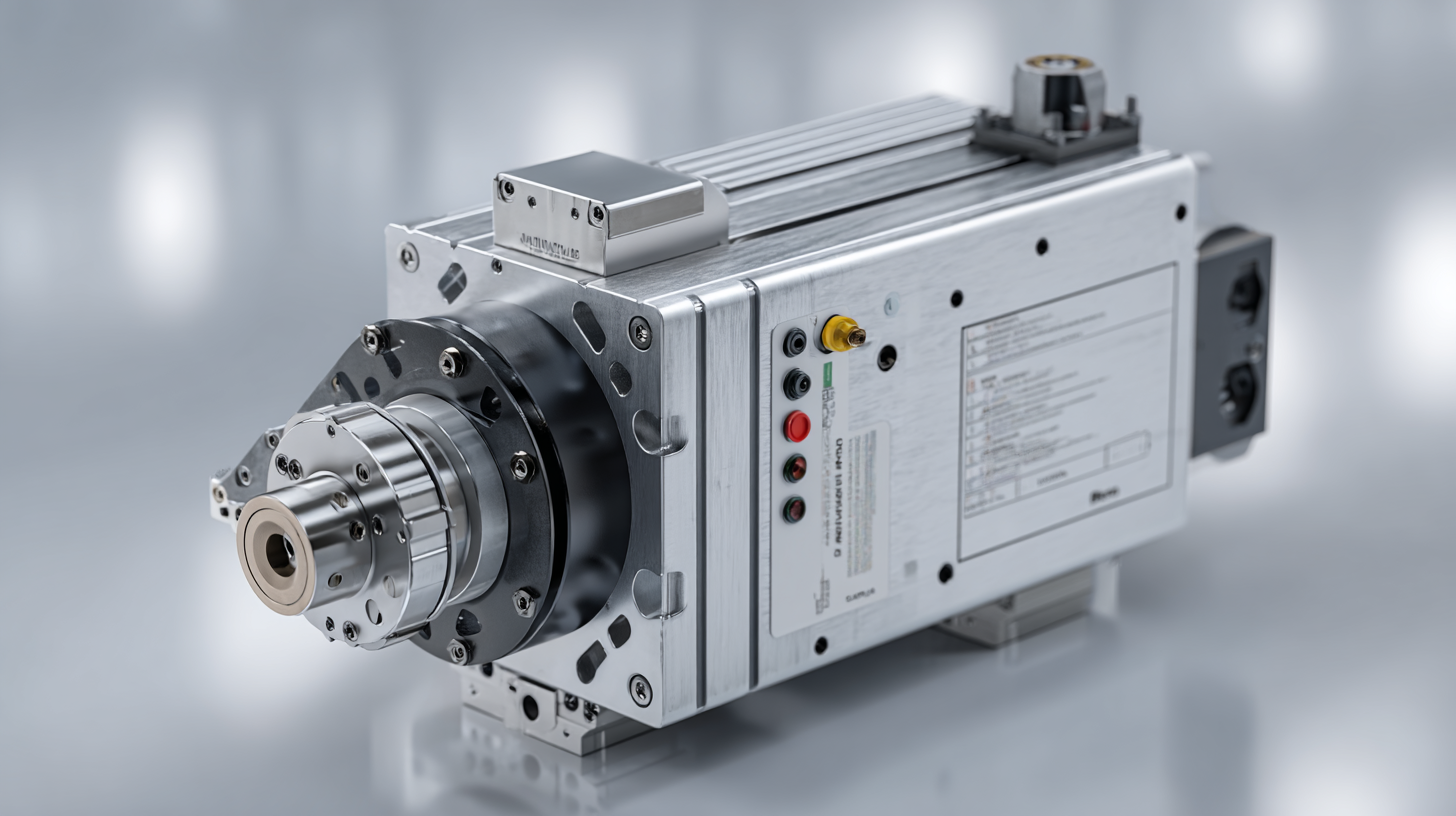

Key Features to Look for in the Best Industrial Servo Motors

In the rapidly evolving industrial landscape, selecting the right servo motor can significantly impact efficiency and performance. As projected data indicates, the global servo motor market is set to expand from a valuation of USD 13.52 billion in 2024 to a robust growth at a CAGR of 6.9% between 2025 and 2030. This expansion underscores the increasing reliance on advanced motion control systems in various sectors, particularly automotive and manufacturing.

When investing in industrial servo motors, key features should not be overlooked. It's crucial to consider the type of motor, such as AC or DC, along with the operating voltage—low, medium, or high. Additionally, assess the motor's capabilities in handling high-dynamic applications, such as those found in servo drive systems designed for precise control and speed. Innovations like adaptive control systems are also noteworthy; they offer enhanced performance even in cyber-physical environments facing potential threats. As industries push toward automation, focusing on these essential features will ensure you make a smart investment in your operational capabilities.

Cost Savings: How Investing in Servo Motors Can Boost Your Bottom Line

Investing in servo motors can lead to significant cost savings for industrial operations, ultimately enhancing your bottom line. One of the primary advantages of servo motors is their ability to improve energy efficiency. Unlike traditional motors, servo systems can adjust their speed and torque precisely according to the demands of the task at hand. This adaptability means that they consume only the energy necessary for specific operations, leading to lower utility bills over time.

In addition to energy savings, servo motors reduce maintenance costs. Their design includes fewer moving parts compared to conventional motors, which translates to less wear and tear. This reliability minimizes downtime and lowers maintenance interventions, allowing your machinery to run smoothly and efficiently. Moreover, the enhanced precision that servo motors provide can result in reduced material waste during production processes, further contributing to cost efficiency. By embracing servo technology, companies can realize not only operational excellence but also a substantial boost to their overall profitability.

The Role of Automation in Enhancing Servo Motor Performance

The role of automation in enhancing servo motor performance cannot be overstated, especially as industries face increasing demands for efficiency and precision. With the robotic automation actuator market projected to grow significantly by 2034, the integration of automation technologies into servo systems is becoming a necessity rather than an option. Automation not only streamlines processes but also enhances the responsiveness and adaptability of servo motors, allowing for greater performance in manufacturing environments.

Furthermore, the growth of markets such as industrial smart motors and servo drives highlights the crucial connection between automation technology and motor innovation. As these markets expand, we are seeing advancements in smart motor designs that leverage automated systems for improved control and efficiency. These developments are driven by the need for precise motion control, which is essential in modern manufacturing and various other sectors relying on automation. By investing in advanced servo motors now, businesses can ensure they are at the forefront of this automation revolution, reaping the benefits of enhanced productivity and reduced operational costs in the years to come.

Future Trends in Industrial Servo Motors: What You Need to Know

As we look toward 2025, the evolution of industrial servo motors is shaping the landscape of automation and manufacturing. One significant trend is the integration of artificial intelligence (AI) and machine learning into servo motor technology. These advancements promise enhanced precision, efficiency, and adaptability, allowing manufacturers to optimize their processes with real-time data analysis and predictive maintenance.

The ability of AI-driven servo motors to learn from operational data means they can adapt to changing conditions, significantly reducing downtime and maintenance costs.

Another key trend is the increasing emphasis on energy efficiency and sustainability in industrial applications. Innovations in materials and design are leading to servo motors that consume less energy while delivering higher performance.

As industries face mounting pressure to reduce their carbon footprints, investing in advanced servo motor technology not only makes economic sense but also supports corporate sustainability goals.

By adopting these cutting-edge solutions, businesses position themselves favorably in a competitive market, ensuring they remain at the forefront of industrial advancements.