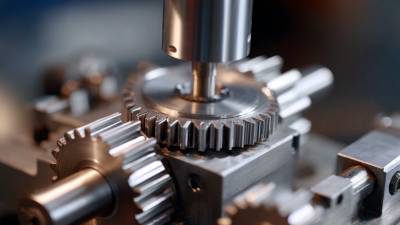

2025 Top Worm Gear Reducer Applications and Benefits for Industries

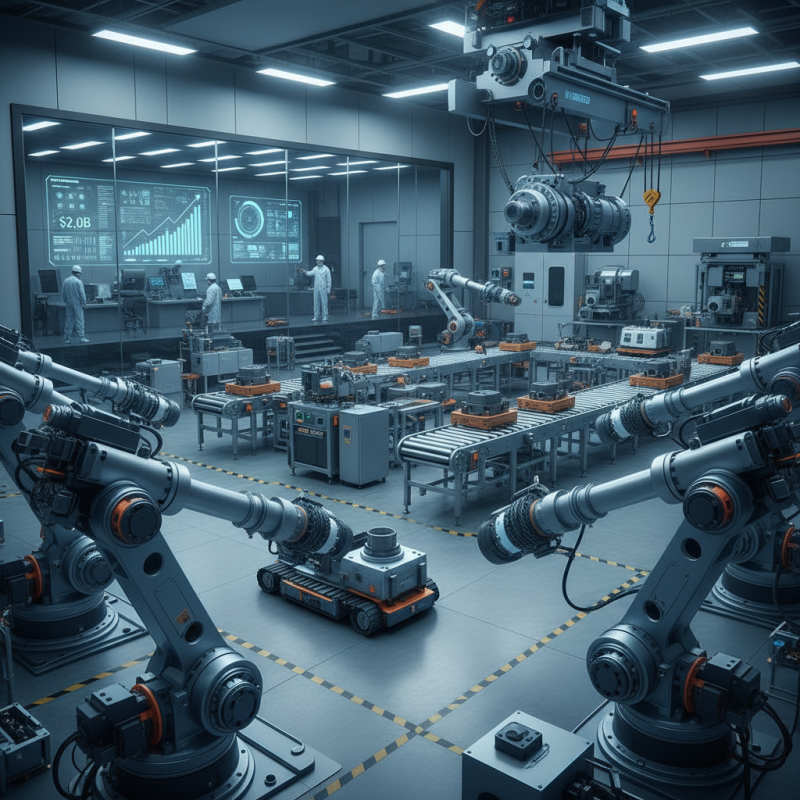

Worm gear reducers are integral components in numerous industrial applications, providing significant advantages in terms of torque amplification and efficient speed reduction. According to the Global Worm Gear Reducer Market report from ResearchAndMarkets, the market was valued at approximately $1.5 billion in 2022 and is projected to grow at a CAGR of 5.2% through 2025. This growth is largely driven by the increasing demand for automation across various sectors, such as manufacturing, materials handling, and robotics, where precise control and high reliability are essential.

As industry experts emphasize the importance of these components, Dr. John Marshall, a leading mechanical engineer specializing in gear technologies, notes, "The adaptability and efficiency of worm gear reducers make them a preferred choice for applications requiring high torque and low speed." With industries continually evolving towards advanced technology solutions, worm gear reducers are set to play a crucial role in enhancing system performance and reducing operational costs. This article will explore the top applications of worm gear reducers in 2025 and highlight the benefits they offer across various fields, showcasing their significance in today’s industrial landscape.

Top Industries Utilizing Worm Gear Reducers in 2025

In 2025, various industries continue to leverage worm gear reducers due to their high efficiency and compact design. These devices are primarily utilized in sectors such as manufacturing, automotive, and renewable energy, all of which demand robust and reliable machinery performance. According to a recent market analysis report, the global worm gear reducer market is projected to grow at a CAGR of around 6.5% from 2023 to 2028, driven by the increasing need for precise motion control and torque multiplication in various applications.

In the manufacturing sector, worm gear reducers significantly enhance operational efficiency by enabling machinery to handle heavy loads with minimal energy consumption. Industries are employing these systems in conveyor belts, mixers, and packaging equipment due to their ability to provide high gear ratios and compact footprints. As highlighted by the Manufacturing Trends Report 2024, approximately 30% of manufacturing operations are integrating advanced gearing systems, including worm gear reducers, to optimize their production lines.

Similarly, the automotive industry is adopting worm gear reducers in electric and hybrid vehicles to improve power transmission efficiency. The integration of these reducers contributes to better vehicle performance and energy savings, aligning with the industry's goal of reducing carbon emissions. According to the Automotive Technology Forecast, the demand for advanced gear systems, such as worm reducers, is expected to rise, with a projected increase of over 20% in their application within new vehicle designs by 2025. This trend underscores the critical role worm gear reducers play in advancing industrial innovation in key sectors.

Key Benefits of Worm Gear Reducers for Industrial Applications

Worm gear reducers have emerged as a vital component in various industrial applications, thanks to their unique design and inherent advantages. One of the key benefits is their ability to provide high torque output while maintaining a compact size. According to a report from the Power Transmission Distributors Association (PTDA), worm gear reducers can achieve gear ratios of up to 100:1, making them ideal for applications requiring significant speed reduction. This high efficiency allows industries such as manufacturing and packaging to optimize their machinery for enhanced performance and reliability.

Another significant advantage of worm gear reducers is their self-locking capability. This feature enables the system to prevent back-driving, ensuring safety and stability in heavy-load conditions. As per a recent analysis by the International Journal of Engineering Research, utilizing worm gear reducers in conveyor systems can reduce energy consumption by nearly 20%, contributing to lower operational costs and a smaller carbon footprint. The ability to maintain precise positioning further benefits applications in robotics and automation, where high accuracy is paramount.

Tips: When selecting a worm gear reducer, consider the load and speed requirements carefully to find the optimal ratio that maximizes efficiency. Additionally, regular maintenance can enhance the lifespan of the reducers, ensuring consistent performance in demanding environments.

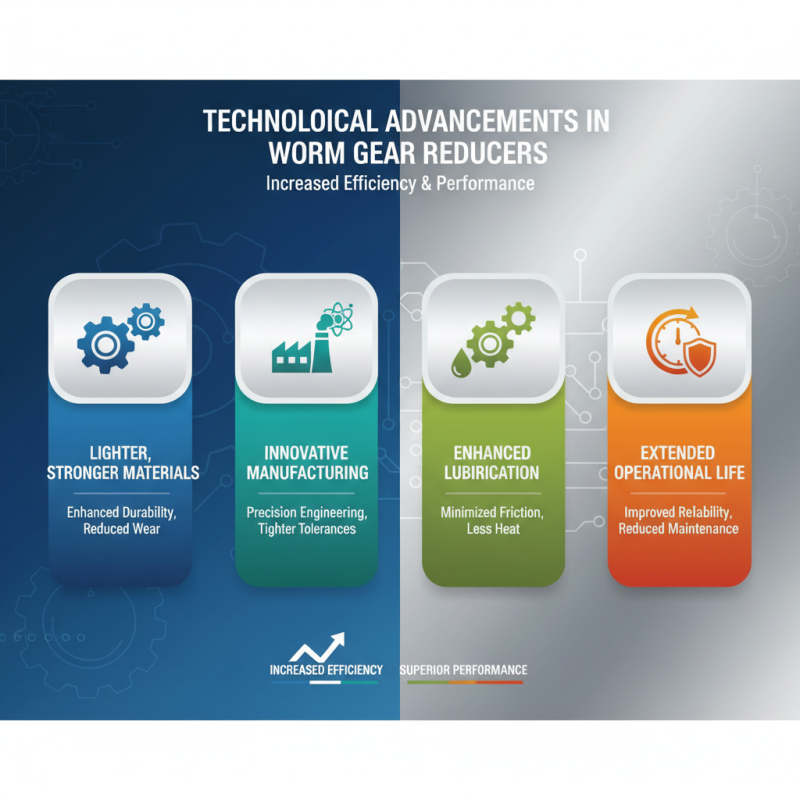

Technological Advancements in Worm Gear Reducer Designs

Recent technological advancements in worm gear reducer designs have significantly improved their efficiency and performance across various industrial applications. Innovations in materials and manufacturing techniques have led to the development of lighter, yet stronger components that enhance durability and reduce wear over time. Enhanced surface treatments and lubrication systems further minimize friction and heat generation, making these reducers more reliable and extending their operational lifespan.

Additionally, the integration of smart technologies into worm gear reducers has transformed how industries monitor and manage their equipment. IoT-enabled sensors can provide real-time data on performance metrics, allowing for predictive maintenance and reducing downtime. This shift towards more intelligent systems not only boosts productivity but also empowers manufacturers to optimize their processes, contributing to energy savings and cost reductions. As industries continue to adopt these advancements, worm gear reducers are proving to be essential components in driving efficiency and innovation across multiple sectors.

Comparison of Worm Gear Reducers with Other Gear Types

Worm gear reducers are widely recognized for their unique advantages compared to other gear types, particularly in applications where space constraints and high torque are critical. According to a report by the Global Gearbox Market, worm gear reducers can achieve torque multiplication higher than standard helical and bevel gears, making them ideal for heavy-duty applications in industries such as automotive, manufacturing, and material handling. Specifically, worm gear reducers can provide gear ratios of up to 100:1, offering a significant reduction in speed alongside an increase in output torque. This capability lends itself well to machines requiring precision and strength in compact configurations.

When comparing worm gear reducers to other gear types, efficiency is a notable factor. Although worm gears typically exhibit lower efficiency rates—ranging from 50% to 90%—due to sliding contact between the worm and the wheel, they excel in self-locking applications. In scenarios where load retention is necessary, such as in lifting or hoisting mechanisms, this feature is invaluable. A study from the American Gear Manufacturers Association notes that the self-locking characteristic of worm gears reduces the risk of back-driving, offering enhanced safety and reliability, particularly in industrial applications. Furthermore, the low-noise operation of worm gear reducers makes them suitable for environments where noise reduction is paramount. This combination of benefits makes worm gear reducers a preferred choice in various sectors, despite some trade-offs in efficiency.

2025 Worm Gear Reducer Applications and Benefits Comparison

Future Trends in Worm Gear Reducer Usage Across Industries

As industries continue to evolve, the application of worm gear reducers is increasingly being tailored to meet the specific needs of various sectors. One notable trend is the growing demand for energy efficiency. According to a recent report by MarketsandMarkets, the global worm gear reducer market is projected to reach $4.6 billion by 2025, driven by the need for energy-saving technologies. Industries such as manufacturing, automotive, and renewable energy are prioritizing equipment that minimizes power consumption while maintaining optimal performance, making worm gear reducers an attractive option.

Furthermore, the rise of automation and robotics is reshaping the way worm gear reducers are utilized. A study by Mordor Intelligence points out that the automation market is expected to grow at a CAGR of 9.4% from 2021 to 2026. This surge enhances the demand for compact and reliable gear solutions, leading to an increased integration of worm gear reducers in robotic systems. As industries adopt more sophisticated technologies, the versatility and ability of worm gear reducers to handle a wide range of speeds and torque requirements will be essential for the advancements in automation processes. This trend showcases the adaptability of worm gear reducers to the future landscape of industrial applications.

2025 Top Worm Gear Reducer Applications and Benefits for Industries

| Application Area |

Benefits |

Future Trends |

| Manufacturing |

High torque transmission, compact design |

Increased automation and precision |

| Robotics |

Efficiency and reliability |

Integration with AI technologies |

| Aerospace |

Lightweight and durable |

Advanced materials usage |

| Conveyor Systems |

Smooth operation and reduced noise |

Smart conveyor systems with IoT |

| Marine Applications |

Corrosion resistance and reliability |

Sustainability practices |