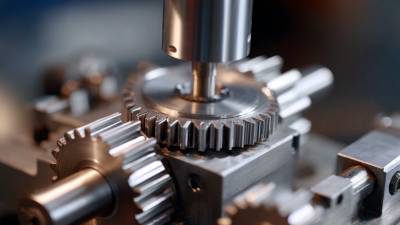

2026 Top Metal Forming Machine Trends You Need to Know?

As the manufacturing world evolves, the role of the metal forming machine becomes increasingly vital. Experts like John Smith, a renowned metal forming machine engineer, emphasize, “Innovation in metal forming will set the pace for the entire industry.” The trends for 2026 will reflect this innovation and necessity for efficiency.

In recent years, the push for sustainability has changed metal forming practices. Many companies are adopting eco-friendly materials and processes. This shift requires machines that are both versatile and energy-efficient. As technology advances, we see new methods emerge, reshaping production lines.

However, not every development has been smooth. Some manufacturers struggle to keep up with rapid changes. Investments in new technology often come with risks and uncertainties. Adapting to these trends means facing challenges head-on while maintaining quality and productivity in metal forming. The future is bright yet complex for the industry.

Emerging Technologies Shaping Metal Forming Machines in 2026

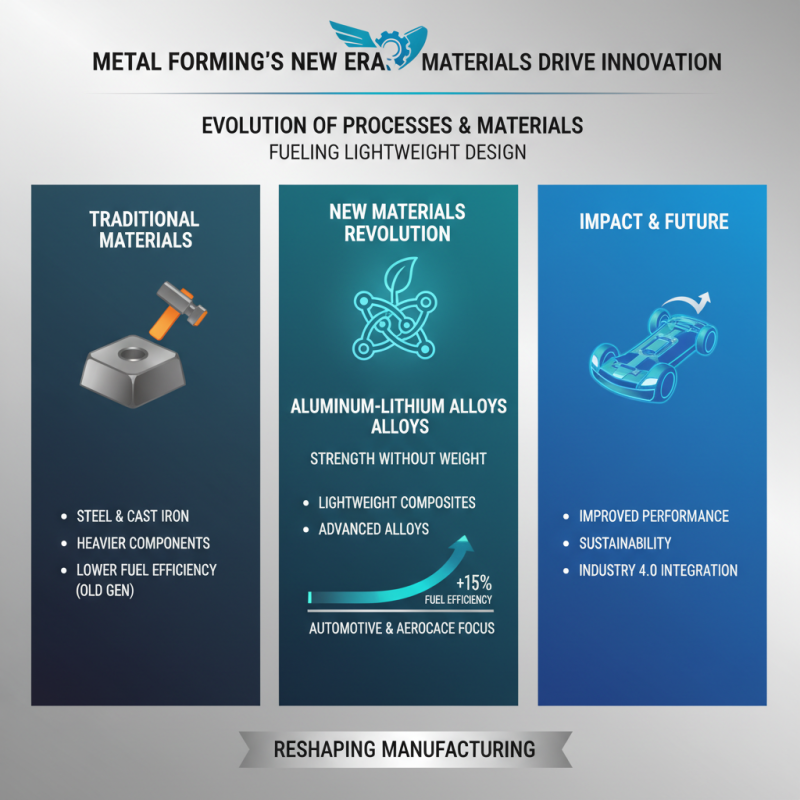

The landscape of metal forming machines is rapidly evolving due to emerging technologies. In 2026, trends such as automation, advanced materials, and AI integration will play pivotal roles. Automation improves efficiency and precision. Machines that adapt to new tasks can significantly reduce production time. AI technologies will enhance predictive maintenance, minimizing downtime and unexpected failures.

Tip: Invest in training for your team. Understanding new technologies will maximize their effectiveness.

Additive manufacturing is gaining traction. Techniques like 3D printing complement traditional forming methods. This hybrid approach enables complex designs that were once unfeasible. However, challenges remain in material compatibility and process integration. Evaluating your current systems is crucial.

Tip: Evaluate and test new materials. Ensure they align with your production goals.

Smart sensors will redefine how metal forming machines operate. These sensors provide real-time data on performance and quality control. However, the influx of data can be overwhelming. It's important to refine data management practices. Focus on actionable insights rather than simply collecting information.

2026 Top Metal Forming Machine Trends

Sustainability Trends in Metal Forming: Eco-Friendly Innovations

In the metal forming industry, sustainability is becoming increasingly crucial. Eco-friendly innovations are now at the forefront. Companies are adopting greener methods to reduce environmental impact. This shift not only addresses regulatory demands but also meets consumer expectations for sustainable practices.

New technologies are emerging that focus on minimizing waste. Recyclable materials are gaining popularity. For example, using biodegradable lubricants can significantly reduce harmful emissions during the forming process. Additionally, energy-efficient equipment is being developed. This helps lower energy consumption while maintaining productivity levels.

**Tips:** Consider integrating renewable energy sources to power your operations. It can lead to significant cost savings in the long run. Regular maintenance of your machines can improve efficiency and reduce waste. Stay informed about the latest advancements in sustainable materials. This could enhance your competitive edge while contributing to the environment. Adopting eco-friendly practices isn't always easy, but the long-term benefits are clear.

2026 Top Metal Forming Machine Trends You Need to Know? - Sustainability Trends in Metal Forming: Eco-Friendly Innovations

| Trend |

Description |

Eco-Friendly Benefits |

Projected Impact by 2026 |

| Energy-Efficient Machinery |

Tools that use less energy during operation. |

Reduces carbon footprint. |

Expect a 30% reduction in energy consumption. |

| Recyclable Materials |

Use of materials that can be recycled after use. |

Supports circular economy practices. |

Increase in recycled material usage by 40%. |

| Smart Manufacturing |

Integrating IoT and AI for improved precision. |

Minimizes waste and enhances efficiency. |

Potential waste reduction by 25%. |

| Water Conservation Technologies |

Techniques that reduce water usage in processes. |

Conserves water resources. |

Water usage down by 50% expected. |

| Waste Reduction Techniques |

Methods to minimize scrap and off-cuts. |

Less landfill waste. |

Anticipate a 35% reduction in scrap material. |

Automation in Metal Forming: AI and Robotics Integration

The integration of AI and robotics in metal forming processes is reshaping the industry. Automation offers precise control and efficiency, which is vital for today's competitive landscape. More companies are investing in automated systems to enhance production rates and reduce costs.

However, adopting these new technologies can be challenging. Companies must evaluate their existing workflows. Upgrading machinery without a clear strategy may lead to disruptions. Investing in staff training is crucial. Workers need to feel confident operating new systems alongside traditional methods.

Tip: Start with small-scale automation projects. This allows for a smoother transition. Train your team on basic robotics. Regular feedback sessions can help address issues early. Monitor performance closely to ensure optimal results. Embracing automation is a journey, not a sprint.

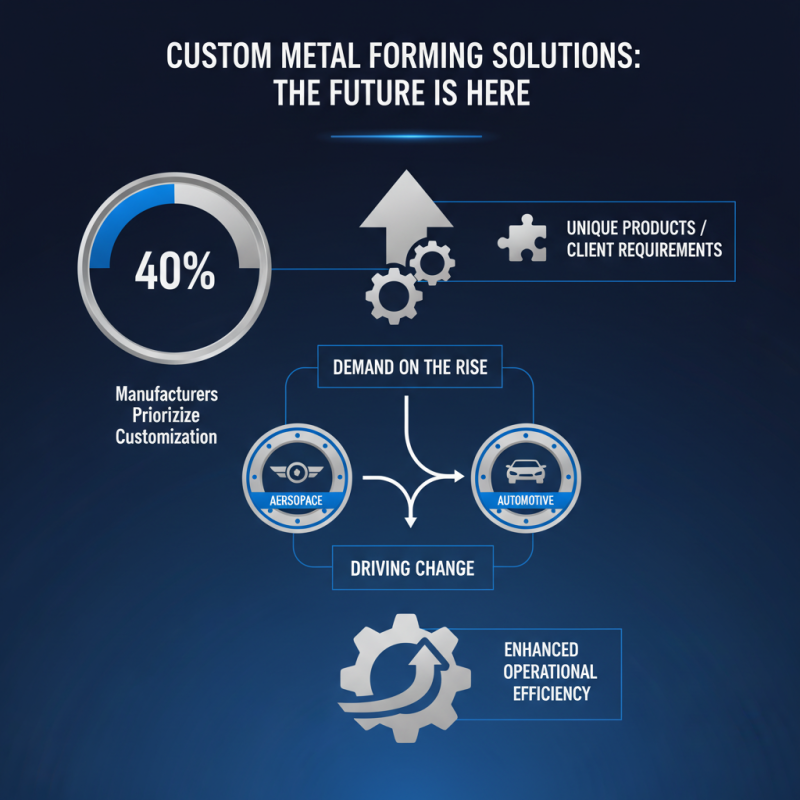

Future Market Trends: Demand for Customizable Metal Forming Solutions

The demand for customizable metal forming solutions is on the rise. According to industry reports, over 40% of manufacturers now prioritize customization in their operations. This trend reflects the need for unique products tailored to specific client requirements. Industries such as automotive and aerospace are driving this change. They require precise shaping and forming techniques. Custom solutions often enhance operational efficiency.

Additionally, a report by MarketWatch notes that the market for metal forming is expected to grow at a CAGR of 5.2% from 2021 to 2026. This growth suggests a strong shift towards flexible production methods. However, the challenge remains in balancing customization with cost-effectiveness. Many manufacturers face difficulties in maintaining consistent quality while adapting machines for varied specifications.

Investments in advanced technologies, such as AI and automation, will be crucial. These technologies can streamline production processes. Such improvements can lead to less waste and faster turnaround times. Yet, there are still gaps in workforce training and machine adaptability. Addressing these issues will be essential for companies looking to thrive in this evolving landscape.