Top 5 Benefits of Using Metal Forming Machines for Your Manufacturing Needs

In the fast-evolving landscape of manufacturing, metal forming machines have become indispensable tools that not only enhance productivity but also significantly improve precision in production processes. According to a recent report by the International Federation of Robotics, the global market for metal forming technology has seen a remarkable growth of approximately 7% annually over the past five years, driven by advancements in automation and demand for high-quality components. This growth trend underscores the vital role that metal forming machines play in modern manufacturing.

Expert in metal forming processes, Dr. Emily Zhang, noted, "The adoption of advanced metal forming machines is crucial for manufacturers looking to optimize their operations and cater to the increasingly sophisticated needs of their clients." This statement highlights a fundamental shift as industries strive for efficiency and reliability, making it imperative for businesses to invest in cutting-edge metal forming technology. In this article, we will explore the top five benefits of using metal forming machines and how they can transform your manufacturing needs, positioning your operations for greater success in a competitive market.

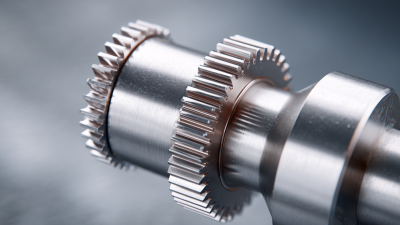

Enhanced Precision and Accuracy in Manufacturing Processes

The use of metal forming machines in manufacturing significantly enhances precision and accuracy, which are crucial for producing high-quality products. These machines are designed to create intricate shapes and complex designs while maintaining tight tolerances. The advanced technology incorporated into modern metal forming equipment allows for real-time adjustments during production, minimizing deviations from specifications. This capability ensures that each part manufactured meets the required standards, reducing waste and the need for rework.

Moreover, the precision achieved with metal forming machines leads to improved overall efficiency in the manufacturing process. With higher accuracy in shaping metal components, manufacturers can streamline operations, reduce material costs, and enhance production speed. This level of efficiency not only meets customer demands but also positions manufacturers favorably in competitive markets. By investing in metal forming technology, businesses can ensure that their products are not only precise but also reliable and durable, fostering customer satisfaction and loyalty.

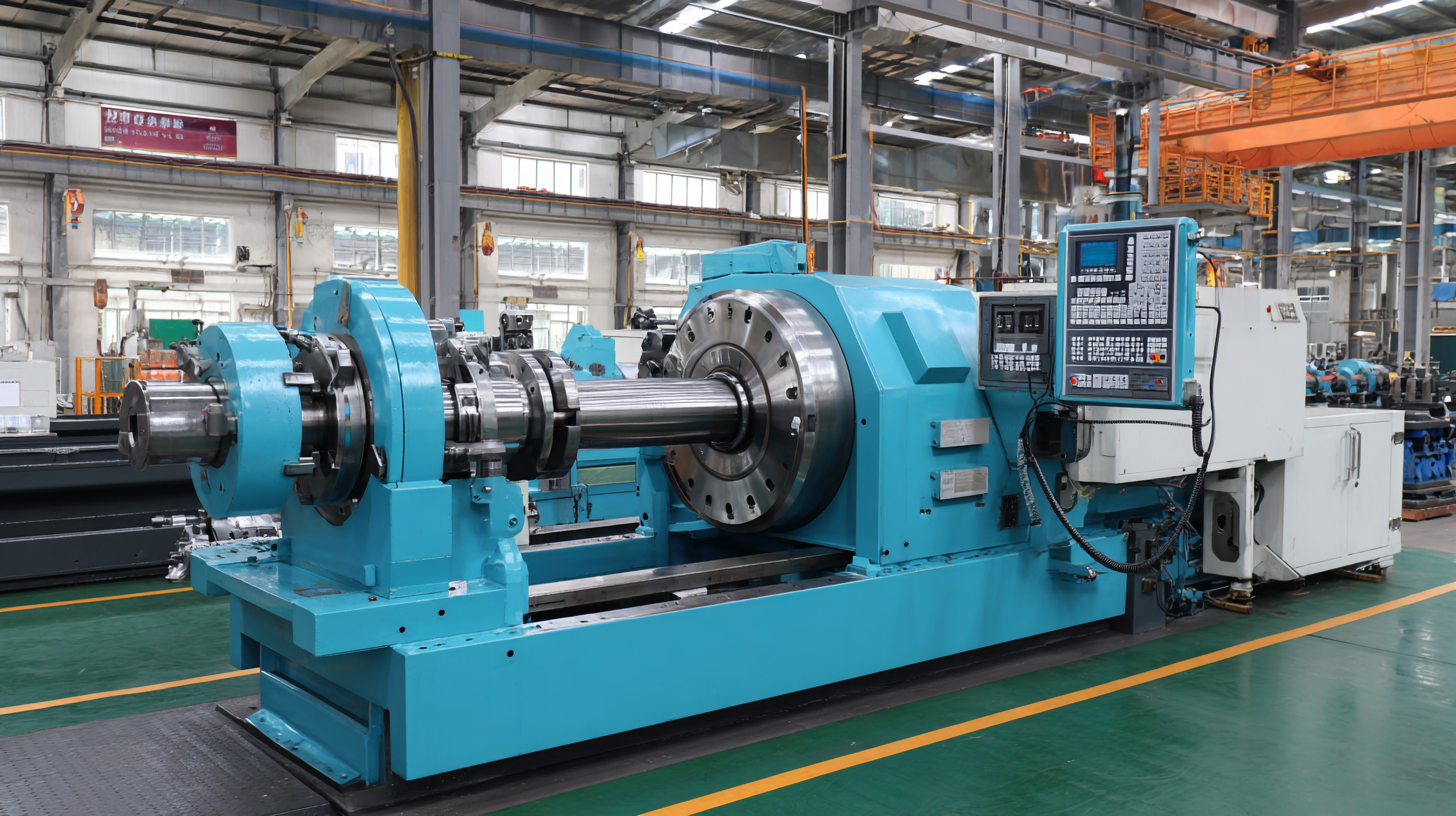

Increased Production Efficiency and Reduced Lead Times

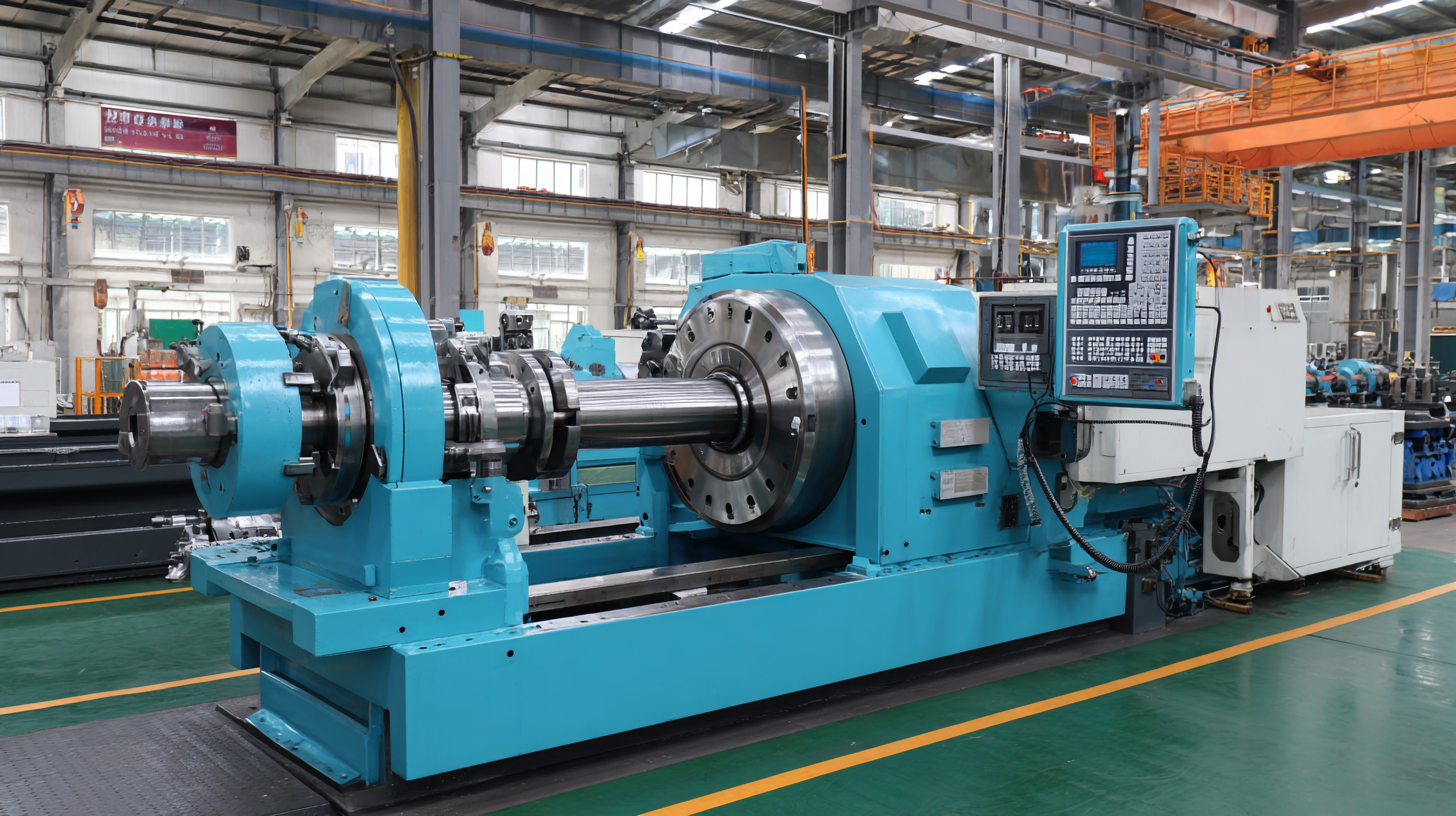

Metal forming machines have revolutionized the manufacturing landscape, particularly in enhancing production efficiency and reducing lead times. According to a report by Grand View Research, the global metal forming market is projected to reach $157.4 billion by 2025, driven by the demand for advanced manufacturing techniques that optimize the production process. Metal forming machines leverage automation and precision engineering, which can significantly decrease cycle times and increase output. For instance, modern CNC machines enable manufacturers to produce complex shapes with minimal setup time, thus allowing for faster turnaround on production orders.

Moreover, the implementation of metal forming technologies can lead to a notable reduction in lead times. The Boston Consulting Group reported that companies adopting automated metal forming processes can experience lead time reductions of up to 30%. This efficiency not only satisfies customer demand more swiftly but also enhances inventory management, thereby reducing holding costs. With the industry's shift towards Just-In-Time (JIT) manufacturing, the integration of metal forming machines becomes essential for maintaining competitiveness and responsiveness in today's fast-paced market. As manufacturers seek to streamline their operations, investing in these advanced machines proves to be a strategic decision aligned with industry trends.

Cost-Effectiveness through Reduced Material Waste and Labor

Utilizing metal forming machines in manufacturing significantly enhances cost-effectiveness by minimizing material waste. Traditional methods often leave behind scraps that contribute to overall production costs. However, advanced metal forming technologies are designed to optimize material usage, allowing manufacturers to shape metal with precision. This reduction in waste not only decreases the expenses associated with raw materials but also promotes a more sustainable approach to production, leading to long-term benefits.

In addition to reduced material waste, metal forming machines streamline labor efficiency. Automated processes reduce the need for manual intervention, which can be both time-consuming and prone to errors. By investing in these machines, manufacturers can allocate their workforce to more value-added tasks, ultimately resulting in improved productivity. The combination of lower material costs and enhanced labor efficiency positions companies to achieve greater profitability while maintaining high-quality output.

Versatility in Handling Various Materials and Complex Shapes

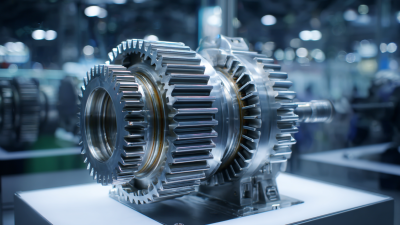

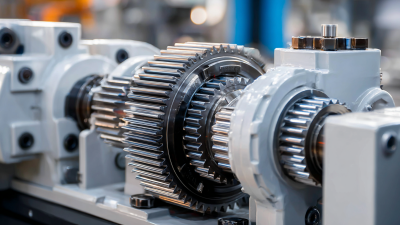

Metal forming machines are renowned for their versatility, allowing manufacturers to work with a wide range of materials. Whether it’s steel, aluminum, or exotic alloys, these machines can efficiently manipulate different types of metals to meet specific project requirements. This adaptability makes them an essential asset in industries such as automotive, aerospace, and construction, where the ability to use various materials can significantly enhance product performance and durability.

Moreover, the design capabilities of metal forming machines enable the creation of complex shapes that might be impossible to achieve with traditional machining processes. Their advanced technologies, including CNC programming and hydraulic systems, allow for precise control and intricate detailing. This means that manufacturers can produce everything from simple brackets to sophisticated components with intricate geometries, catering to the evolving demands of today’s marketplace. By leveraging these capabilities, companies can not only improve their production efficiency but also expand their design possibilities, ultimately leading to innovative solutions and a competitive edge in the manufacturing sector.

Top 5 Benefits of Using Metal Forming Machines for Your Manufacturing Needs

| Benefit |

Description |

Applications |

| Versatility |

Can work with a wide range of metals and alloys, allowing for customized production. |

Automotive, aerospace, and industrial machinery. |

| Precision |

High accuracy in forming metal parts, reducing material waste. |

Manufacturing of intricate components and parts. |

| Efficiency |

Faster production times compared to traditional methods. |

High-volume manufacturing environments. |

| Complex Shapes |

Ability to create complex geometries that are difficult to machine. |

Architectural components, molds, and dies. |

| Cost-Effectiveness |

Reduced labor costs and material losses lead to higher profitability. |

Small to medium-sized production runs. |

Improved Product Quality and Consistency through Advanced Technologies

Advanced technologies in metal forming machines significantly enhance product quality and consistency, addressing a critical need in the manufacturing sector. According to a recent report by MarketsandMarkets, the metal forming machines market is projected to reach $12.4 billion by 2027, indicating a growing trend towards adopting these advanced solutions. These machines leverage innovative techniques, such as computer numerical control (CNC), to execute meticulous designs with precision. This advancement minimizes human error, ensures tighter tolerances, and consistently produces high-quality components that meet industry standards.

Furthermore, the integration of automation and robotics in metal forming processes has drastically improved efficiency. A study published by the International Journal of Advanced Manufacturing Technology found that manufacturing facilities utilizing automated metal forming machines experienced a 25% increase in output consistency. By reducing variations and defects during production, manufacturers can achieve higher first-pass yields, consequently reducing waste and lowering production costs. This level of consistency not only enhances customer satisfaction but also boosts the competitiveness of manufacturers in an increasingly demanding marketplace.