2026 Best Industrial Automation Trends You Need to Know?

Industrial automation is rapidly evolving. The year 2026 promises to bring groundbreaking trends that will transform industries. Companies are turning to automation to enhance efficiency and reduce costs. These changes not only impact production lines but also redefine workforce roles.

Emerging technologies like AI and machine learning are key players in industrial automation. They offer predictive maintenance and smarter decision-making processes. Companies must adapt to these innovations to remain competitive. However, implementing new systems can pose challenges. Employees may require retraining, and integration with existing systems can be complex.

The future of industrial automation is bright but not without its hurdles. Businesses need to stay aware of these trends to harness the full potential of automation. It’s essential to reflect on the impacts and ensure responsible implementation. This balance will shape the factories of tomorrow.

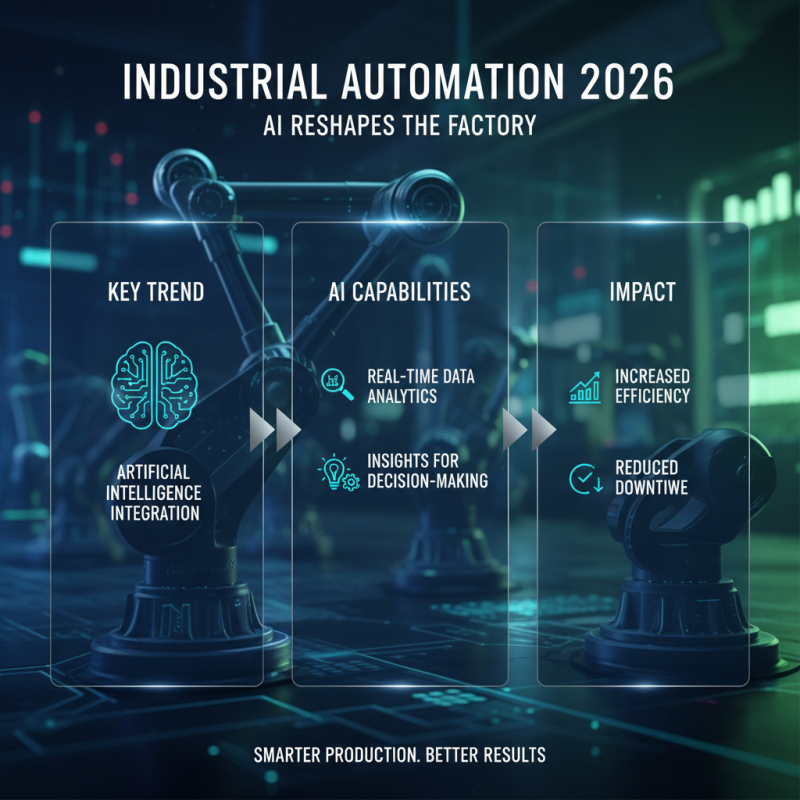

Emerging Technologies Shaping Industrial Automation in 2026

Emerging technologies are reshaping industrial automation in 2026. One significant trend is the integration of artificial intelligence. AI can analyze data in real-time, providing insights for better decision-making. This leads to increased efficiency and reduced downtime in production processes.

Another noteworthy development is the rise of collaborative robots, or cobots. These machines work alongside humans, enhancing productivity without replacing jobs. While they can take on repetitive tasks, human oversight is still necessary. Companies must carefully balance automation with the human touch.

Additionally, advancements in IoT are creating smart factories. These facilities use interconnected devices for monitoring and control. However, challenges remain in data security and integration. Striking a balance between innovation and safety is vital for successful implementation. As we approach 2026, industries must navigate these complexities to fully harness automation's potential.

Key Trends in AI and Machine Learning for Automation

Artificial Intelligence (AI) and machine learning are reshaping industrial automation. These technologies allow machines to learn from data. They can adapt and improve processes without human intervention. Automated systems powered by AI can predict maintenance needs, reducing downtime. This leads to smoother operations and increased productivity.

However, integrating AI in automation is not without challenges. Data quality is crucial for effective machine learning. Inaccurate or biased data can produce flawed results. Companies must focus on data governance to ensure reliability. Another consideration is the workforce. Employees may feel threatened and need training to adapt to new technologies.

The future of industrial automation hinges on these AI advancements. Enhanced robotics and smart machines will play a vital role. But organizations cannot overlook the human factor. Balancing technology with a skilled workforce will be essential to fully realize the potential of AI and machine learning.

2026 Best Industrial Automation Trends You Need to Know

| Trend |

Description |

Impact Level |

Adoption Rate (%) |

| AI-Powered Predictive Maintenance |

Utilizing AI algorithms to predict equipment failures before they occur. |

High |

65 |

| Robotics Process Automation (RPA) |

Automation of routine tasks using software bots for improved efficiency. |

Medium |

70 |

| Digital Twin Technology |

Creating a virtual model of physical systems for real-time monitoring and analysis. |

High |

60 |

| Edge Computing for IoT |

Processing data closer to the source to reduce latency and bandwidth use. |

Medium |

55 |

| AI-Driven Quality Control |

Implementing AI to enhance product quality by identifying defects in real-time. |

High |

50 |

The Role of IoT in Enhancing Industrial Operations

The Internet of Things (IoT) is transforming industrial operations. Sensors and devices connected to the internet collect real-time data. This information helps improve decision-making and streamline processes. For instance, factories can monitor machinery health continuously. This allows for predictive maintenance, reducing unexpected downtimes.

However, not all implementations are seamless. Some companies face challenges integrating IoT with existing systems. Data overload can be a problem, making it hard to identify critical issues. There is also a need for skilled personnel to analyze the data. Without proper interpretation, valuable insights may go unnoticed.

Despite these hurdles, the potential of IoT in automation is undeniable. A connected workspace enhances collaboration and efficiency. Manufacturers can adapt to market demands quickly. This agility can lead to a more sustainable operational model. Embracing IoT may require careful planning, but the rewards can be significant.

Sustainable Practices in Industrial Automation for 2026

Sustainable practices are becoming essential in industrial automation as we approach 2026. Companies are increasingly seeking ways to reduce their environmental footprint. Energy-efficient machinery and smart technologies can help achieve this goal. However, adaptation to these practices is often slow and filled with challenges.

One common hurdle is the initial investment cost. Many companies hesitate to invest in new automation systems. They fear the switch might disrupt operations. This hesitation can lead to missed opportunities. The long-term savings on energy and maintenance might outweigh these initial expenses, but many still struggle to see this vision.

Moreover, integrating sustainable practices requires employee training. Workers need to understand new systems and processes. However, there may be resistance to changing established routines. It's important to address this resistance and encourage a culture of sustainability. Regular workshops and incentives can motivate employees to embrace these changes. The ecosystem of industrial automation is evolving, yet not all players are ready for the shift.

The Importance of Cybersecurity in Automated Systems

As industries lean heavily on automation, cybersecurity must take center stage. Automated systems are increasingly vulnerable to cyber threats. These attacks can disrupt operations and lead to significant financial losses. Companies need to prioritize cybersecurity measures. Ignoring this aspect can leave systems open to breaches. The consequences of such vulnerabilities can be devastating.

Tips for enhancing cybersecurity include regular risk assessments. Conducting these evaluations helps identify weaknesses in your automated systems. Also, ensure that software updates are frequent. Outdated systems are prime targets for attackers. Finally, employee training plays a crucial role. Everyone in the organization should know how to recognize potential threats.

Balancing automation and security is not easy. Some systems may require complex solutions, which can be hard to integrate. Companies must invest time and resources to find the right fit. Remember, a single lapse can lead to severe repercussions. Be proactive in securing automated systems.