How to Choose the Right Worm Drive Gear for Your Project

When embarking on a project that requires specific mechanical components, selecting the right parts is crucial for ensuring optimal performance and longevity. Among various gearing systems, the worm drive stands out as a popular choice due to its unique design and functionality. Unlike conventional gear systems, worm drives offer a high reduction ratio, which makes them ideal for applications where space is limited and precision is essential. This article will guide you through the key considerations to take into account when choosing a worm drive gear.

Understanding the intricacies of worm drives can be complex, but recognizing their advantages remains straightforward. By evaluating factors such as load capacity, shaft speed, and environmental conditions, you can make an informed decision that aligns with your project's requirements. Additionally, it's imperative to consider the materials and construction quality of the worm drive gear, as these factors significantly influence durability and performance. As we delve deeper into the selection process, this article will highlight the essential features and specifications that will help you choose the right worm drive gear for your next endeavor.

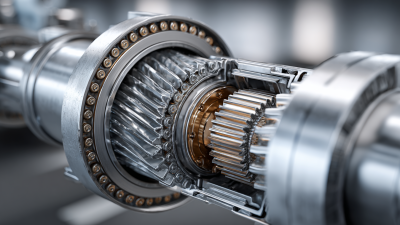

Understanding the Basics of Worm Drive Gears and Their Applications

Worm drive gears are integral components used in various applications, characterized by their unique ability to transmit motion between non-parallel shafts. Understanding the basic principles of these gears is crucial for selecting the right one for your project. A worm gear typically consists of a worm, which is a screw-like component, and a worm wheel, which engages with the worm to create motion. This design allows for substantial gear reduction in a compact space, making it ideal for applications where space is limited.

One common issue faced with worm drive gears is backlash, a phenomenon where there is a slight gap between the gear teeth that can lead to inefficiencies and uneven motion. This issue highlights the importance of selecting a gearbox with appropriate design features to minimize backlash. Additionally, advancements in 3D printing technology have allowed for the creation of customizable worm gearbox models, which can be adjusted for specific applications. Whether in robotics, automotive systems, or manufacturing machinery, understanding the basic mechanics and applications of worm drive gears will equip you to make informed choices for your engineering projects.

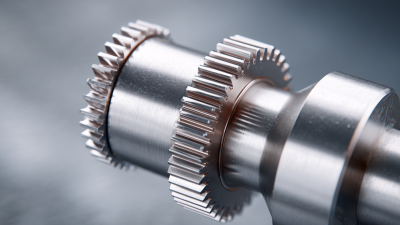

Key Factors to Consider When Selecting a Worm Drive Gear

When selecting a worm drive gear for your project, there are several key factors to consider that can greatly impact performance and longevity. First and foremost, it's crucial to assess the torque requirements of your application. Worm drives are known for their ability to reduce speed while increasing torque, so determining the necessary output torque will help you select a gear that meets these demands without overloading.

Another important factor is the gear ratio. The ratio determines how input speed translates into output speed and torque. A higher gear ratio decreases speed but increases torque, making it ideal for heavy load applications. Conversely, a lower ratio provides higher speeds, suitable for lighter loads. Additionally, consider the material of the gears; materials such as bronze and steel offer different strengths and wear properties, influencing the gear's performance under various conditions. Opting for the right combination of torque, gear ratio, and material will ensure the efficiency and reliability of your worm drive gear assembly.

How to Choose the Right Worm Drive Gear for Your Project - Key Factors to Consider When Selecting a Worm Drive Gear

| Factor |

Description |

Importance |

| Gear Ratio |

Determines the speed and torque of the output based on the input. |

High |

| Material |

Affects durability, weight, and resistance to wear and tear. |

Medium |

| Load Capacity |

Refers to the maximum load the gear can handle without failure. |

High |

| Size and Dimensions |

Should fit within the design constraints of your project. |

Medium |

| Efficiency |

How well the gear transmits power without losses. |

High |

| Noise Level |

Impact of gear operation on the overall noise of the system. |

Low |

| Cost |

Overall price can impact project budget significantly. |

High |

Comparing Different Types of Worm Drive Gears for Specific Needs

When selecting the right worm drive gear for your project, it’s essential to compare the various types available to best meet your specific needs. Worm drive gears are commonly utilized in applications requiring high torque and low-speed output. There are different designs, such as single-start and multi-start worms, which greatly influence the gear ratio and efficiency. Single-start worms offer higher reduction ratios but can be less efficient than their multi-start counterparts, which allow for quicker movement but with increased complexity.

**Tips:** When assessing the performance you need, consider the load and speed of your application. High-load scenarios may benefit from robust materials and larger diameters in worm gears, while speed-oriented tasks may require a focus on reducing friction.

Moreover, materials play a crucial role in the durability and performance of worm drive gears. Options like bronze or plastic for the worm wheel, combined with a steel worm, can enhance wear resistance and lower friction. It's important to choose materials that will withstand the environment in which they will operate, ensuring longevity and efficiency.

**Tips:** Always evaluate the operating conditions of your project—humidity, temperature, and exposure to contaminants can impact material selection significantly.

Comparison of Different Types of Worm Drive Gears

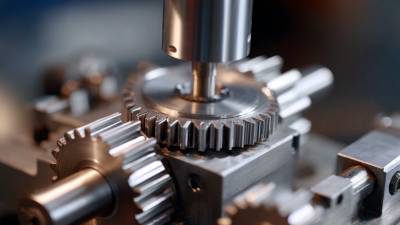

How to Calculate Gear Ratios for Optimal Performance

When selecting the right worm drive gear for your project, calculating gear ratios is essential for achieving optimal performance. Gear ratios determine the relationship between the input and output speeds of a system, affecting torque and overall efficiency. To calculate gear ratios, divide the number of teeth on the driven gear by the number of teeth on the driving gear. This simple formula provides insight into how many times the input gear must turn to achieve one complete rotation of the output gear.

Understanding the implications of gear ratios can significantly impact your project's success. A higher gear ratio often results in increased torque, making it ideal for applications requiring heavy lifting or low-speed operation. Conversely, a lower gear ratio offers higher speeds, suitable for tasks demanding quicker responses. Evaluating your project's specific needs in terms of speed and torque will enable you to select the appropriate worm drive gear, ultimately leading to enhanced performance and efficiency.

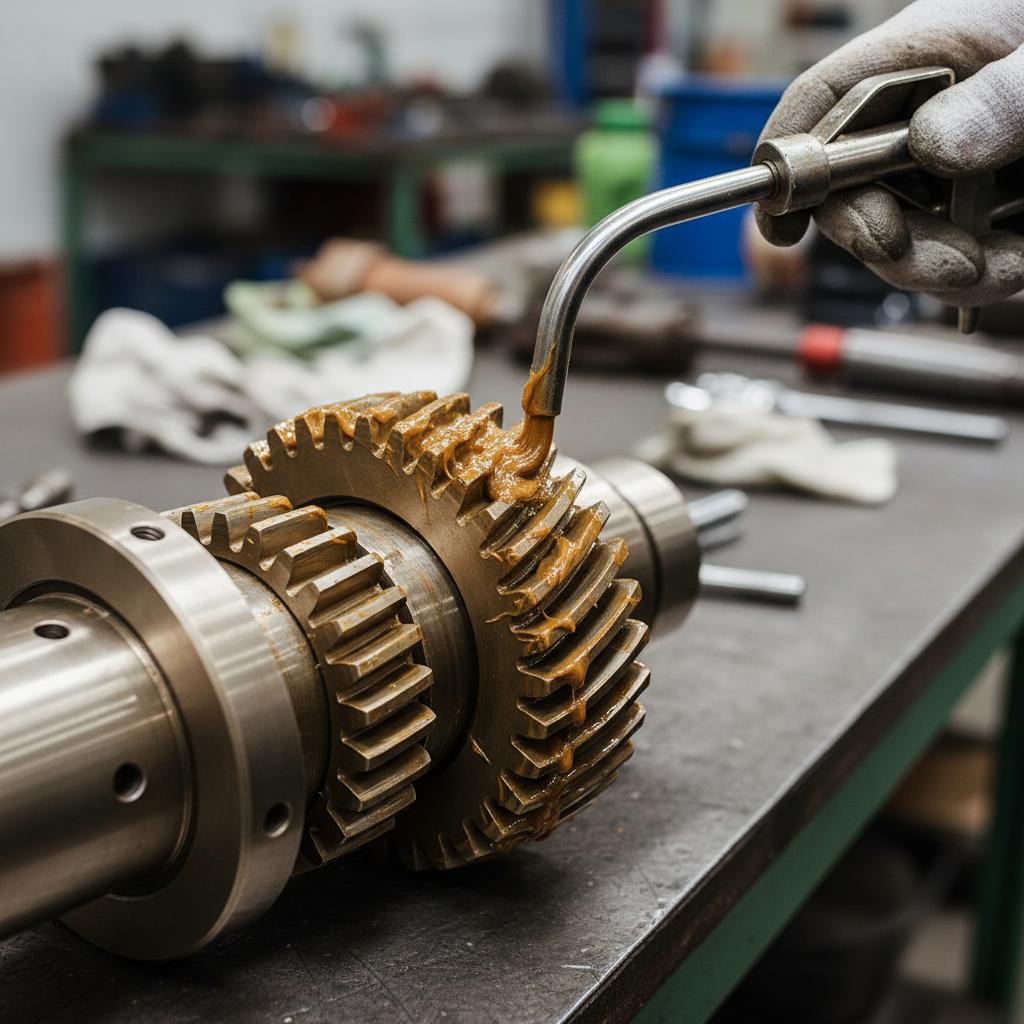

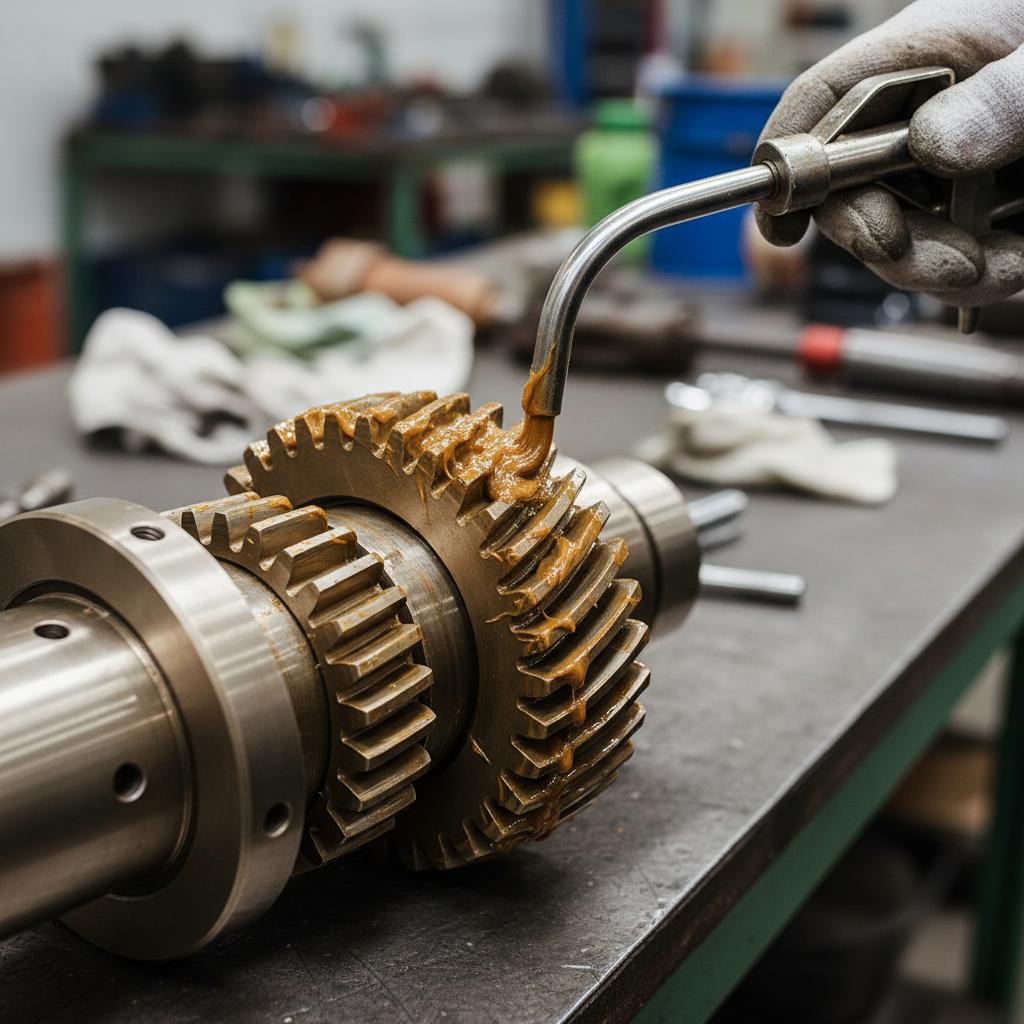

Maintenance Tips for Prolonging the Life of Your Worm Drive Gear

Worm drive gears are known for their ability to transmit motion at high ratios while maintaining compact sizes. However, ensuring their longevity requires regular maintenance. According to a report by the American Gear Manufacturers Association, approximately 50% of gear failures are attributed to poor maintenance practices. To prolong the life of your worm drive gear, routine inspections and lubrication are key. Use high-quality lubricants designed for worm gear applications, which can reduce friction and wear, enhancing efficiency significantly.

Additionally, proper alignment during installation is crucial. Misalignment can lead to uneven load distribution, increasing the risk of premature wear. The Machinery Failure Prevention Technology report emphasizes that maintaining correct alignment can reduce operating costs by up to 30%. Regularly checking for signs of wear, such as unusual noises or temperature fluctuations, can also help identify potential issues before they lead to catastrophic failures. Implementing these maintenance practices not only extends the lifespan of your worm drive gear but also contributes to overall operational efficiency and cost-effectiveness in your project.