How to Choose the Best Filling Equipment for Your Business Needs

Choosing the best filling equipment for your business needs is crucial in optimizing production efficiency and maintaining product quality. The global filling equipment market is projected to reach USD 8.55 billion by 2025, driven by the increasing demand for automation and the growing food and beverage industry. As manufacturers look to enhance their operational efficiency, the choice of filling equipment becomes not just a technical decision but a strategic one that can influence the overall success of the business.

According to industry expert Dr. Emily Carter, a leading authority in filling technology, "Selecting the right filling equipment is paramount to achieving a balance between speed and accuracy, which directly impacts customer satisfaction and bottom-line profitability." Dr. Carter emphasizes that the right equipment should not only cater to current production requirements but also have the scalability to adapt to future business needs. With a multitude of options available, businesses must carefully consider factors such as production volume, product characteristics, and budget constraints when exploring filling equipment solutions. This exploration lays the groundwork for making informed decisions that can set a business on the path to success in today's competitive market.

Understanding Different Types of Filling Equipment Available in the Market

When selecting the best filling equipment for your business, it's essential to understand the various types available in the market. The Dual Chamber Syringe (DCS) filling machine, designed for highly sensitive applications, offers a precise and effective solution, particularly for pharmaceuticals and biotechnology products. It is available in fully automatic, semi-automatic, and manual configurations, catering to different production scales and requirements. Fully automatic machines deliver high efficiency and minimal human intervention, while semi-automatic and manual options provide flexibility for smaller operations or specialized tasks.

Another significant player in the filling equipment landscape is the pilot aseptic filling machine, particularly relevant for industries that require a sterile environment for their products. These machines are engineered to maintain strict contamination controls and can handle various container types, ensuring product integrity. As technological advancements drive innovation in this space, understanding the specific needs of your production process will help you choose the right equipment, balancing factors such as capacity, automation level, and product safety to align with your business objectives.

Comparison of Different Types of Filling Equipment

Evaluating Your Business Production Capacity and Filling Requirements

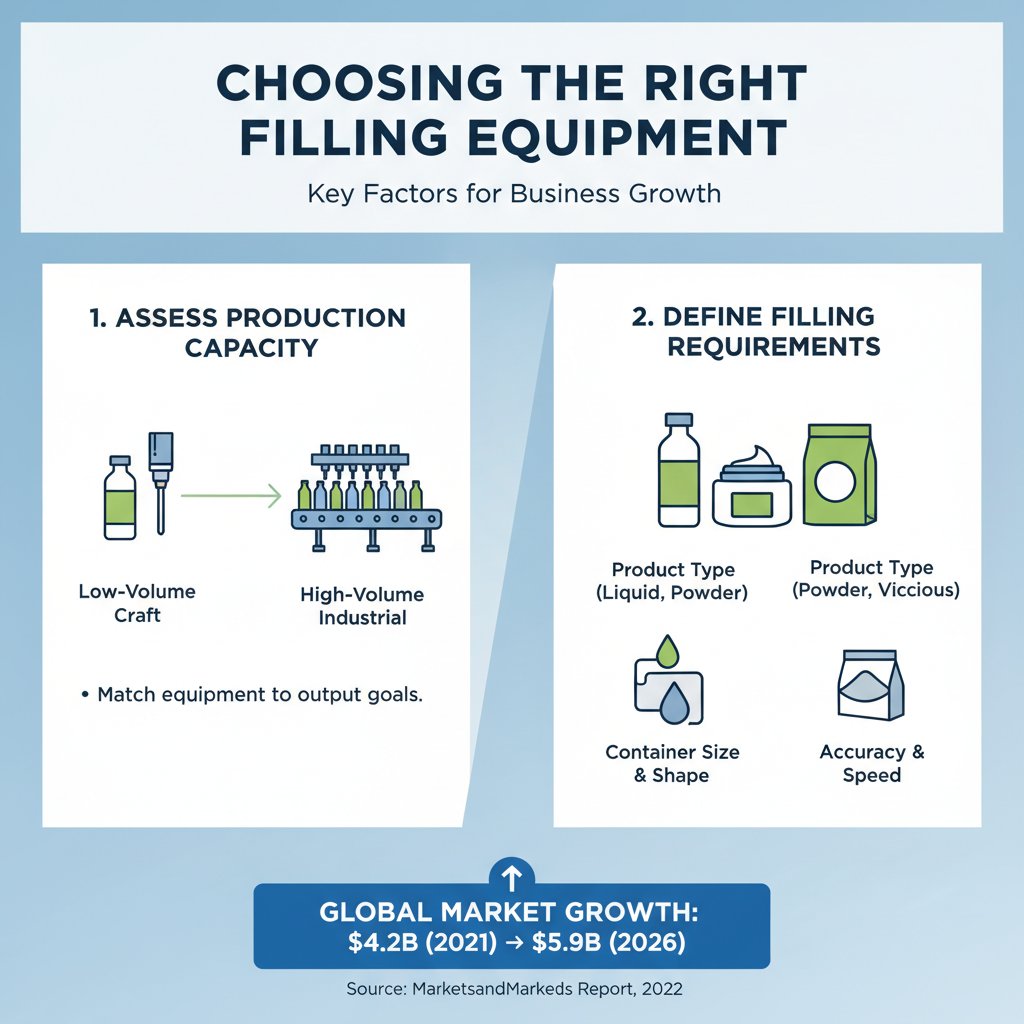

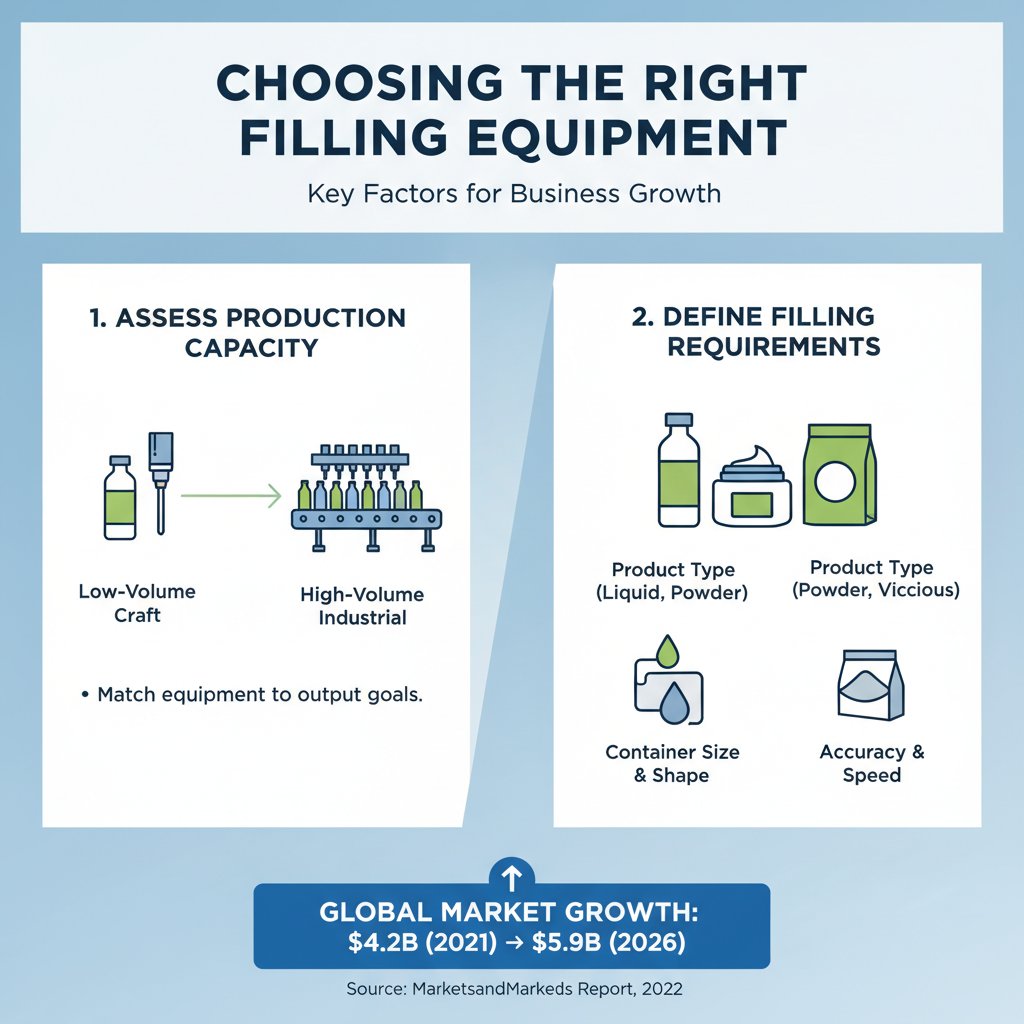

When choosing the best filling equipment for your business, understanding your production capacity and specific filling requirements is paramount. According to a 2022 report by MarketsandMarkets, the global filling equipment market is projected to grow from $4.2 billion in 2021 to $5.9 billion by 2026, underscoring the increasing demand for efficient filling solutions tailored to diverse production scales. Businesses must assess their output goals—whether low-volume craft production or high-volume industrial filling—to determine the necessary equipment features.

The type of product being filled also impacts filling equipment selection. Liquid products, powders, and solids each require specialized machinery to ensure speed and accuracy. The 2023 Food Processing Equipment Market Analysis indicates that companies focusing on liquid filling can boost their operational efficiency by up to 30% with state-of-the-art technology. Furthermore, businesses should evaluate their automation needs: automating filling lines can enhance production rates and reduce labor costs, as evidenced by a study from the International Society of Automation, which found that automated systems can increase production capacity by 50%. Understanding these aspects will guide businesses in selecting the most suitable filling equipment to meet their evolving production demands.

Factors to Consider When Choosing Filling Equipment for Your Products

When choosing filling equipment for your business needs, it’s crucial to consider several key factors that can significantly impact your production efficiency and product quality. First, understanding the type of product you are filling is essential. For instance, according to a recent report by Grand View Research, the liquid filling equipment market is expected to grow at a CAGR of 4.7% from 2021 to 2028, driven by the demand for precision in handling various viscosities—from water-thin liquids to thick pastes. This means that selecting equipment tailored to your specific product type can enhance performance and reduce waste.

Another critical factor is the production capacity required to meet your business demands. The filling speed should align with your output goals; for example, machines with capabilities ranging from 30 to 120 containers per minute can cater to both small and large-scale operations effectively. Moreover, the adaptability of the equipment to accommodate different container sizes is vital for businesses aiming for flexibility in their product offerings. According to MarketsandMarkets, the ability to run multiple SKUs on the same machine can reduce downtime and optimize efficiency, thus providing a competitive advantage in the market.

Assessing Budget Constraints and Cost-Efficiency of Filling Solutions

When selecting filling equipment for your business, assessing budget constraints and cost-efficiency is paramount. According to a recent report from the Packaging Machinery Manufacturers Institute (PMMI), over 60% of businesses cite initial costs as the primary factor influencing their choice of filling solutions. This underscores the importance of conducting a thorough cost analysis that includes not just the purchase price but also long-term operational expenses. For example, a high-speed filling machine may have a higher upfront cost but can result in decreased labor and material costs over time, enhancing overall cost-efficiency.

Further insights from a study by Grand View Research indicate that companies looking for filling equipment should also consider maintenance costs and energy consumption. Research shows that energy-efficient machines can reduce operational costs by up to 30%, thus improving profit margins. Investing in reliable and efficient filling solutions not only meets budgetary requirements but also supports sustainable practices, allowing businesses to remain competitive in a rapidly evolving market. By focusing on these key metrics, businesses can make informed decisions that align with both their financial limitations and operational goals.

How to Choose the Best Filling Equipment for Your Business Needs - Assessing Budget Constraints and Cost-Efficiency of Filling Solutions

| Filling Equipment Type |

Initial Cost ($) |

Operating Cost ($/year) |

Production Rate (units/hour) |

Maintenance Frequency (months) |

Suitability for Viscosity |

| Gravity Filler |

$10,000 |

$2,000 |

30 |

12 |

Low |

| Piston Filler |

$15,000 |

$2,500 |

25 |

6 |

Medium |

| Pump Filler |

$20,000 |

$3,500 |

40 |

8 |

High |

| Volumetric Filler |

$25,000 |

$4,000 |

50 |

10 |

Very High |

| Servo Filler |

$30,000 |

$5,000 |

60 |

12 |

Extremely High |

Importance of Maintenance and Support in Filling Equipment Selection

When selecting filling equipment for your business, understanding the importance of maintenance and support is crucial. Reliable equipment is not only about efficiency and output; it heavily depends on the ongoing support and upkeep that ensure optimal performance. A manufacturer that provides comprehensive maintenance services can help minimize downtime, which is essential for maintaining production schedules and customer satisfaction. Regular servicing can also extend the lifespan of your equipment, preventing costly repairs and replacements in the future.

Moreover, choosing a supplier that offers robust support can make a significant difference in your operations. Technical assistance, rapid response times to service requests, and access to replacement parts are vital elements that determine the level of support you can expect. When evaluating different filling equipment options, consider the availability and quality of customer support. A strong maintenance plan, combined with accessible technical support, will empower your business to respond to challenges swiftly, ensuring that your filling processes run smoothly and efficiently for years to come.