How to Choose the Right Precision Gearing for Your Application

In today's rapidly advancing industries, choosing the right precision gearing is critical. Precision gearing plays a vital role in various applications, from robotics to aerospace. Market research indicates that the precision gearing industry is projected to grow significantly, reaching a value of over $24 billion by 2025. According to expert Dr. James W. Taylor, a leading authority in gearing technology, “Selecting the appropriate precision gearing can significantly enhance efficiency and performance in machinery.”

Every application has unique requirements. Factors like load capacity, speed, and alignment must be considered. A miscalculation can lead to inefficiencies or even failures. Precision gearing offers accuracy, but it also demands careful selection. Not all gears are created equal; some may not meet the specific needs of your project. It’s essential to weigh options and reflect on past choices.

Decision-making in precision gearing requires insight and understanding. As industries become more specialized, the available options can be overwhelming. Understanding limitations and knowing when to consult experts can make a difference. Each application poses its challenges, and the ideal solution is not always obvious. Balancing innovation with reliability is key to making informed choices.

Understanding Precision Gearing and Its Importance in Applications

Precision gearing plays a vital role in various applications. These gears ensure accurate motion transfer in machinery. Whether in robotics or automotive systems, they enable precise control. This precision is essential for functions that require exact positioning or speed. Choosing the right gear set can significantly affect overall performance.

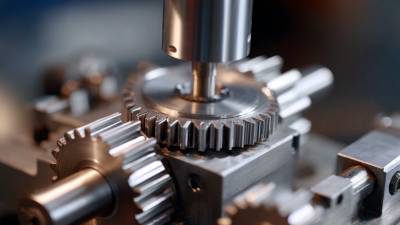

Understanding the specifications of precision gearing is crucial. Factors such as gear ratios, materials, and tolerances can influence efficiency. A small error can lead to larger issues in the system. For example, a loose fit could cause slippage, affecting accuracy. It's important to analyze the application's specific needs before making a decision.

Users often overlook the importance of compatibility. Not every gear works perfectly with other components. This mismatch can lead to mechanical failures. Regular testing and adjustments can help avoid these pitfalls. Evaluating both the operational environment and the load requirements is necessary for optimal selection. Taking time to reflect on these aspects can lead to better, more reliable outcomes.

Key Factors to Consider When Selecting Precision Gearing Solutions

Choosing the right precision gearing for your application involves several key factors. Load capacity is crucial. Think about how much weight the gear will need to support. Too much load can lead to premature failure. Also, consider the speed at which the gears will operate. High speeds may require specific materials to withstand wear.

Another important factor is the pitch and size of the gears. Matching them to your application’s specifications can be tricky. If the gear size is off, it can lead to inefficiencies. A mismatch can cause excessive noise or vibrations, impacting performance. Pay attention to the environment as well. Exposure to dust, moisture, or extreme temperatures may degrade gear performance.

Lastly, manufacturing tolerances are vital. Precision gears must fit together perfectly. Gaps can create backlash, leading to inaccuracies. If tolerances are too loose, gears may not work as intended. This can result in costly downtime. Evaluating these aspects carefully will improve the chances of selecting the best precision gearing for your needs.

How to Choose the Right Precision Gearing for Your Application

| Factor |

Description |

Considerations |

| Load Capacity |

The maximum load that the gearing can handle. |

Evaluate application requirements and safety margins. |

| Precision Level |

The degree of accuracy required in the gear system. |

Determine if high precision is essential for performance. |

| Speed Rating |

The maximum operating speed of the gearing. |

Assess the speed requirements of the application. |

| Material |

The type of material used for the gears. |

Consider durability, weight, and corrosion resistance. |

| Efficiency |

The energy loss in the gearing system. |

Look for a gearing solution with minimal energy loss. |

| Footprint |

The space required for installation. |

Ensure compatibility with available installation space. |

Types of Precision Gears and Their Specific Applications

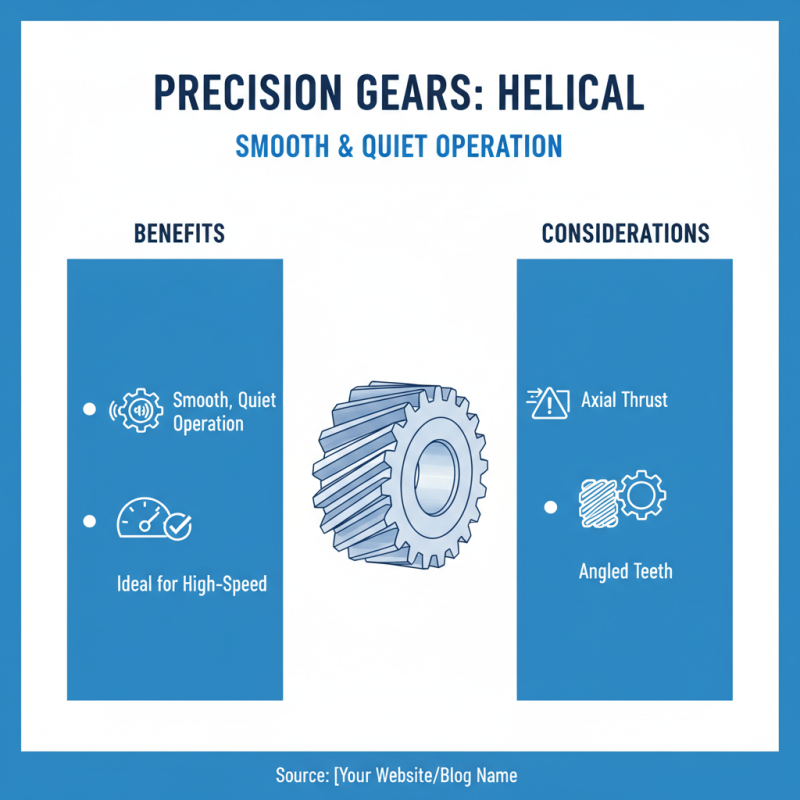

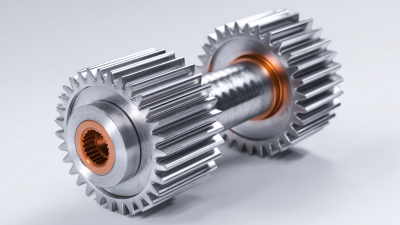

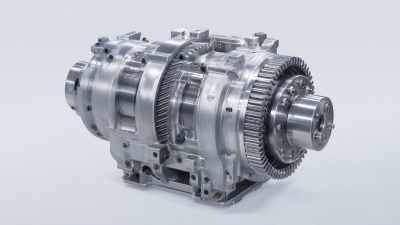

When selecting precision gears, understanding the types available is essential. Helical gears are common in applications requiring smooth operation. They work well in high-speed environments. Their angled teeth reduce noise, creating a quieter machinery experience. However, they may cause axial thrust, which needs attention.

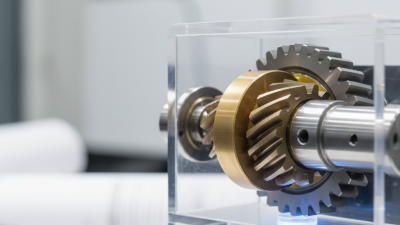

Planetary gears offer compact construction and high torque output. These gears excel in automotive and robotics applications. They distribute loads evenly, but assembly can be tricky. Misalignment during setup can lead to performance issues. Worm gears, on the other hand, provide high reduction ratios. They are often found in heavy machinery. Their non-reversible design can limit applications but enhances safety.

Be mindful of the specific requirements for each application. Consider factors like torque, speed, and space. It’s crucial to evaluate tolerances and ensure compatibility with existing systems. Make informed choices to avoid oversights that could lead to costly mistakes down the line.

Evaluating Material and Design Specifications for Gear Performance

Choosing the right material for precision gearing is crucial. The material impacts strength, durability, and performance. Common choices include steel, aluminum, and plastic. Each has unique properties and potential limitations. For instance, steel is strong but can be heavy. Aluminum is lightweight, yet it may not withstand severe conditions. Consider the environment where gears will operate. Will they face moisture, heat, or corrosive substances? These factors will guide your material selection.

The design specifications also play a significant role in gear performance. Factors like tooth profile, pitch, and backlash must be evaluated carefully. Even a small change can lead to increased wear. Designs that focus on load capacity often sacrifice efficiency. This trade-off needs careful consideration. Sometimes, a more complex gear design may seem tempting, but it can introduce unforeseen challenges. Reflecting on simplicity could yield better results.

Be aware of the limitations of your choices. Testing prototypes can reveal issues not anticipated in the design phase. It's essential to remain open to adjustments based on real-world performance. Precision gearing is about balance—between strength, weight, and functionality. Engage in this process mindfully, recognizing that perfection is a moving target.

Cost-Effectiveness and Lifespan Considerations in Gearing Choices

Cost-effectiveness is a key factor in choosing precision gearing. Selecting the right gear can significantly impact your budget. Lower initial costs might seem attractive, but hidden expenses can arise. Long-term maintenance, replacement parts, and operational efficiency often add up. A cheaper solution today may lead to higher costs tomorrow.

Lifespan is another critical consideration. Gears with robust materials tend to last longer. However, they often come with a higher price tag upfront. It’s essential to assess your application’s demands. Will the gear be under constant stress? If so, investing in a durable gear makes sense. On the other hand, lighter workloads may allow for less expensive options.

Balancing cost and longevity is challenging. You may need to compromise. Investing more initially can yield savings in the long run. Consider the environment where the gears operate. If conditions are harsh, performance may decline. Understanding these factors leads to better choices. Engage with your team and reflect on previous experiences. Each decision shapes your future operations.

Cost-Effectiveness and Lifespan Considerations in Precision Gearing Choices