Transforming Efficiency: The Future of Industrial Automation Solutions in Smart Manufacturing

As the manufacturing landscape continues to evolve, the integration of industrial automation solutions has become crucial for enhancing efficiency and productivity. According to a report by McKinsey, the adoption of automation technologies could increase global manufacturing output by $2 trillion by 2030, signifying a transformative shift in operational capabilities. Moreover, the International Federation of Robotics (IFR) states that the deployment of industrial robots in factories is expected to grow by 20% annually, underscoring the growing reliance on advanced automation systems to optimize production processes. This shift towards smart manufacturing not only streamlines workflows but also facilitates real-time data analysis, enabling manufacturers to adapt swiftly to market demands. As we explore the future of industrial automation solutions, it is essential to understand the strategies that will drive this evolution, empowering businesses to thrive in an increasingly competitive landscape.

The Role of Artificial Intelligence in Enhancing Automation Efficiency

The integration of artificial intelligence (AI) into industrial automation solutions is revolutionizing efficiency in smart manufacturing. AI's ability to autonomously make decisions, continuously learn, and interact naturally is transforming traditional manufacturing processes. Recent advancements reveal how AI has significantly compressed timeframes for complex operations, allowing procedures that once took years to complete by hand to now be achieved in mere months. This rapid enhancement in productivity is crucial as industries seek to streamline operations while maintaining high-quality output.

Moreover, the emergence of AI-driven digital workers is redefining how companies manage their workflows. These AI agents are not merely tools but collaborators that optimize tasks across various sectors, including manufacturing. By automating mundane activities, they enable human employees to focus on higher-level strategic work. The trend towards leveraging AI for automation is gaining momentum, and its implications for efficiency and effectiveness in smart manufacturing are profound, shaping the future of how industries operate and innovate.

Key Technologies Driving the Next Wave of Smart Manufacturing

The landscape of smart manufacturing is rapidly evolving, fueled by key technologies that are driving this next wave of industrial automation solutions. One of the most significant advancements is the integration of artificial intelligence (AI), which enables machines to learn from data and enhance operational efficiencies. With AI, manufacturers can predict equipment failures, optimize production schedules, and reduce downtime, ultimately leading to improved output and cost savings.

Another pivotal technology in smart manufacturing is the Internet of Things (IoT). By connecting machines and devices to the internet, manufacturers can gather real-time data that informs decision-making processes. This connectivity allows for seamless communication between equipment, leading to smarter resource management and processing capabilities. Companies should invest in IoT platforms that are scalable and secure to fully leverage their manufacturing potential.

**Tip:** To improve efficiency, consider conducting regular training sessions for your workforce on new technologies and systems. Engaging employees in the automation process not only boosts morale but also ensures that everyone is equipped to utilize advanced tools effectively.

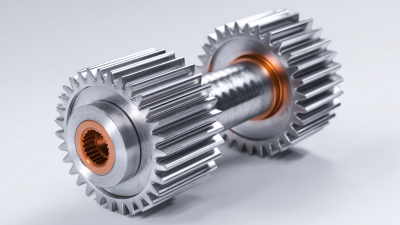

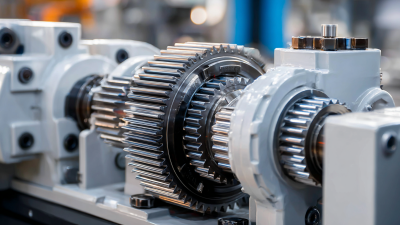

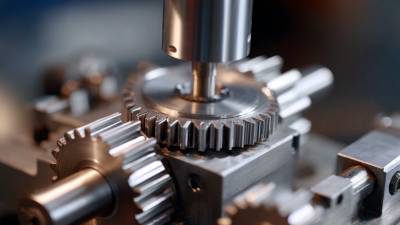

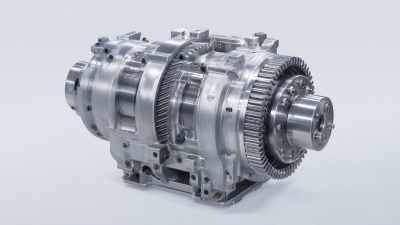

In addition, robotics is revolutionizing the manufacturing sector by enhancing productivity through automation. Collaborative robots, or cobots, can work alongside human operators, taking on repetitive tasks while allowing humans to focus on more complex operations. Implementing robotics can streamline workflows and improve overall manufacturing throughput.

**Tip:** Start small with automation projects to evaluate their impact before scaling up. This allows for adjustments and minimizes risk while encouraging innovation within your organization.

Transforming Efficiency: The Future of Industrial Automation Solutions in Smart Manufacturing

| Key Technology |

Description |

Benefits |

Adoption Rate (%) |

| IoT Integration |

Connecting machines and systems to the internet for real-time data exchange. |

Enhanced monitoring and predictive maintenance capabilities. |

75% |

| Artificial Intelligence |

Using algorithms to analyze data and optimize processes. |

Improved decision-making and process optimization. |

60% |

| Machine Learning |

Systems that learn from data and improve over time without explicit programming. |

Enhanced automation and personalized production. |

55% |

| Robotics |

Automated machines performing tasks previously done by humans. |

Increased productivity and safety in manufacturing environments. |

70% |

| Cloud Computing |

Storing and processing data on remote servers accessible via the internet. |

Scalability and flexibility for managing manufacturing data. |

65% |

| Augmented Reality |

Overlaying digital information on the physical world to assist operators. |

Improved training and maintenance processes. |

50% |

Integrating IoT Solutions for Real-Time Data in Industrial Processes

The integration of Internet of Things (IoT) solutions in industrial processes is revolutionizing smart manufacturing, allowing for enhanced

real-time data analytics that drive efficiency and productivity. According to a report by McKinsey, manufacturers that effectively adopt IoT solutions

can boost their productivity by up to 20%. This increase is primarily due to the ability to collect and analyze data from machines and

production lines, enabling quicker decision-making and timely maintenance, which reduces downtime and operational costs.

Moreover, the global IoT in manufacturing market is projected to reach $231 billion by 2025, growing at a CAGR of 25.9%

from 2020. This surge highlights the importance of real-time data in achieving competitive advantage. With IoT, manufacturers can monitor their processes

continuously, gather insights into production performance, and dynamically adjust operations to meet consumer demands.

The ability to leverage real-time data not only enhances operational efficiency but also leads to innovative business models, such as

predictive maintenance and customized production, aligning closely

with the evolving landscape of smart manufacturing.

Challenges and Solutions in Adopting Automation in Manufacturing

The adoption of automation in manufacturing is becoming increasingly critical as industries navigate modern labor challenges. In automotive manufacturing, companies are increasingly considering broader automation to counteract labor shortages and inefficiencies. This trend reflects a significant shift in how manufacturers are viewing the role of machinery not just as tools, but as integral parts of their workforce that can address these contemporary challenges.

In the medical device sector, manufacturers face unique hurdles such as stringent regulatory requirements and the need for high-mix, low-volume production. Automation solutions are emerging as viable answers to these issues by streamlining processes, ensuring compliance, and enhancing production capabilities. Moreover, simulation and offline programming techniques are being adopted to maximize efficiency and mitigate workforce shortages, demonstrating that automation offers not just a technical upgrade, but a strategic advantage in a rapidly evolving industrial landscape.

Future Trends: Predictive Analytics and Autonomous Systems in Industry

The integration of digital twin technology in industrial automation is revolutionizing manufacturing processes, paving the way for enhanced efficiency and productivity. Digital twins create virtual replicas of physical assets and systems, enabling manufacturers to simulate and optimize operations with high-resolution modeling. This technological advancement is particularly significant for predictive analytics, which relies on real-time data to forecast potential failures and optimize maintenance schedules, thereby minimizing downtime and operational disruptions.

As industries embrace autonomous systems, they leverage data-driven insights from digital twins to refine product design, improve resource management, and streamline workflows. The ongoing evolution of artificial intelligence further amplifies these benefits, allowing for adaptive learning and decision-making processes that cater to specific operational needs. This convergence of predictive analytics and autonomous capabilities underscores a transformative shift in smart manufacturing, driving market growth and redefining the landscape of industrial solutions.