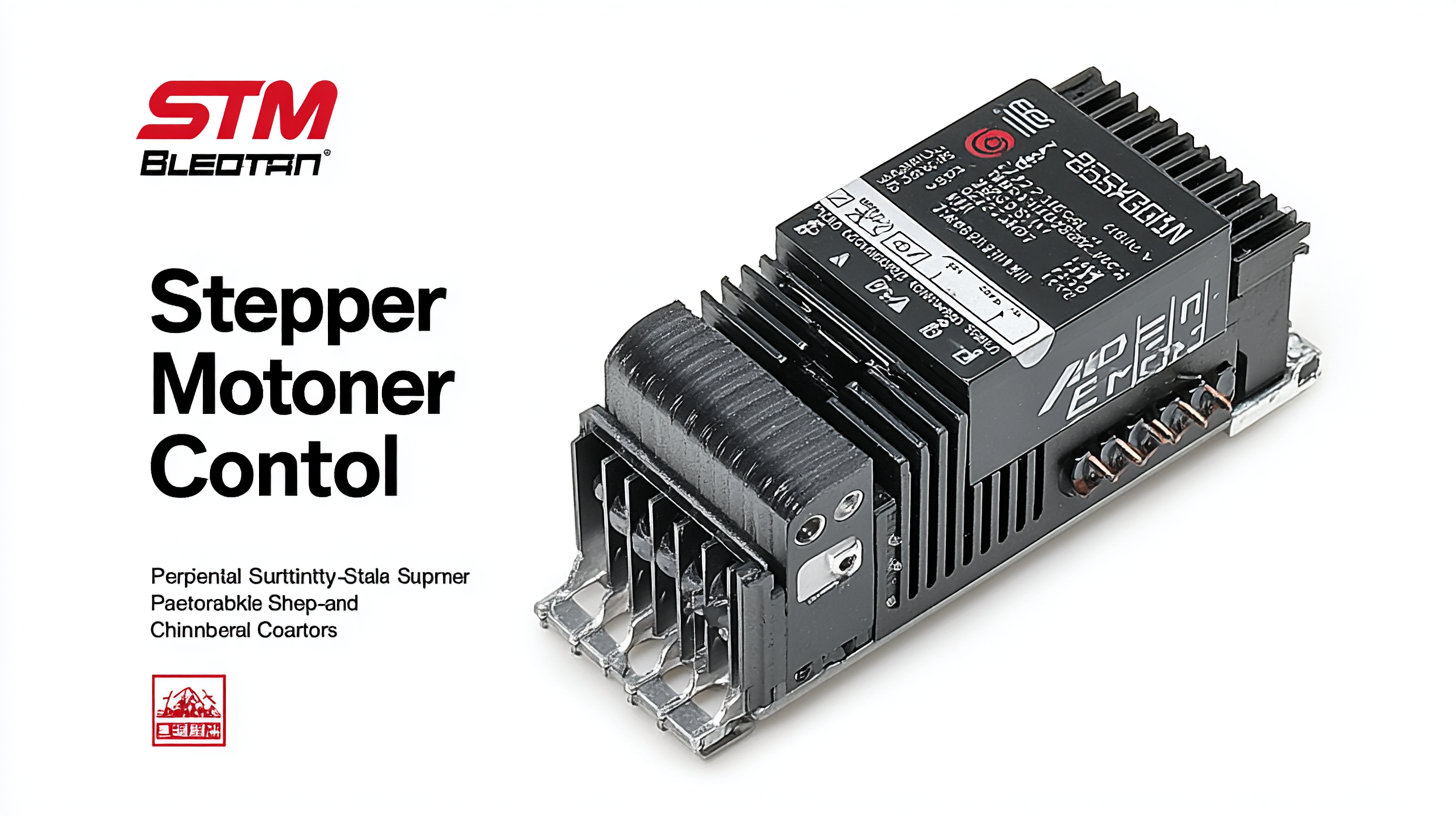

Empowering Global Supply Chains with Premier Stepper Motor Controllers from China

In the rapidly evolving landscape of global supply chains, the demand for precision and reliability is paramount. At the heart of many advanced automation systems lies the Stepper Motor Controller, a crucial component that ensures accurate movement and control in various industrial applications. China has emerged as a powerhouse in manufacturing these essential devices, combining technological innovation with high-quality production to meet the diverse needs of the global market. The mantra "中国制造,以品质赢得世界尊重" (China Manufacturing, Winning the World's Respect through Quality) resonates strongly in this context, highlighting China's commitment to delivering superior products that empower businesses worldwide.

As we delve deeper into the advantages of Chinese-made Stepper Motor Controllers, we will explore how they not only enhance operational efficiency but also contribute to the seamless integration of cutting-edge technologies in supply chains across the globe.

The Role of Stepper Motor Controllers in Modern Supply Chain Efficiency

In the fast-evolving landscape of modern supply chains, stepper motor controllers play a pivotal role in enhancing efficiency and precision. These devices are crucial for automating various processes in industries such as manufacturing, logistics, and packaging. According to a report by MarketsandMarkets, the global stepper motor market is projected to reach $3.5 billion by 2025, driven largely by the increasing demand for automation in production lines. By providing precise control of motor performance, stepper motor controllers significantly reduce operational delays and eliminate errors associated with manual processes.

Moreover, the integration of advanced stepper motor controllers in robotic applications is revolutionizing supply chain dynamics. A study published by Research and Markets indicates that the robotics market, which heavily relies on these controllers, is expected to grow at a compound annual growth rate (CAGR) of 26% from 2020 to 2025. This growth is largely due to the need for greater efficiency and reduced costs in inventory management and fulfillment processes. As stepper motor controllers enable smoother, more accurate movements, they enhance the overall throughput of supply chains, allowing businesses to meet consumer demands more effectively in a globally competitive market.

Understanding Import and Export Certifications for Stepper Motor Products

In the ever-evolving landscape of global supply chains, understanding the intricacies of import and export certifications for stepper motor products is crucial for businesses looking to thrive. Certifications such as CE, RoHS, and UL are essential for ensuring product compliance with international safety and environmental standards. According to a recent report by the International Electromechanical Commission (IEC), the market for stepper motors is projected to grow at a CAGR of 6.2% from 2023 to 2030, highlighting the increasing demand for high-quality motor controllers that meet stringent certification requirements.

When assessing suppliers in China, ensure they possess the necessary certifications to avoid costly delays and failures in compliance. It's recommended to conduct thorough due diligence, requesting copies of certification documentation, and verifying them through official channels. Additionally, consider engaging with third-party inspection companies to ensure the products meet both your expectations and international standards.

Tip: Always stay updated on the latest regulatory changes in the regions you operate. Many industries often undergo shifts in compliance requirements, especially in electronics. Establishing connections with local industry groups can provide valuable insights and keep you informed about crucial changes.

Key Benefits of Sourcing from Chinese Manufacturers for Global Supply Chains

Sourcing stepper motor controllers from Chinese manufacturers offers significant advantages for global supply chains. According to a report by Statista, China accounted for over 28% of the global motor market value in 2021, demonstrating its pivotal role in the industry. The production capabilities and economies of scale in China allow for competitive pricing, which is crucial for businesses aiming to optimize their supply chain costs. Companies can benefit from reduced procurement expenses while maintaining quality, which is essential for meeting consumer demands.

Additionally, Chinese manufacturers are at the forefront of technological advancements in stepper motor controllers. A study by MarketsandMarkets predicts that the global stepper motor market will grow from $3.04 billion in 2022 to $4.23 billion by 2027, driven by innovations in automation and robotics. By partnering with these manufacturers, global supply chains can leverage the latest technologies, ensuring that their systems remain efficient and up to date. The combination of cost-effectiveness and technological advancements positions Chinese stepper motor controllers as a preferred choice for industries looking to enhance their operational efficiencies.

Navigating Compliance and Quality Standards in Stepper Motor Controller Exports

In the competitive landscape of global supply chains, the export of stepper motor controllers from China presents unique challenges, particularly in navigating compliance and quality standards. As the demand for precision and reliability in automation and robotics increases, manufacturers must ensure that their products conform to international regulations such as CE, RoHS, and UL certifications. These certifications not only facilitate access to foreign markets but also instill confidence in buyers regarding the performance and safety of the products they are investing in.

Achieving compliance requires a thorough understanding of both domestic manufacturing regulations and the prerequisites of destination markets. Chinese manufacturers are increasingly adopting international quality management systems like ISO 9001, which play a critical role in quality assurance. By focusing on rigorous testing and quality control processes, companies can enhance their reputation and build lasting relationships with global partners. This commitment to excellence is essential for enhancing competitiveness in a landscape where consumers prioritize quality alongside cost, ensuring that stepper motor controllers exported from China not only meet but exceed international standards.

Future Trends in Supply Chain Management: The Impact of Advanced Motor Technology

As global supply chains continue to evolve, the integration of advanced motor technologies, particularly stepper motor controllers, will play a pivotal role in shaping their future. According to a report by Market Research Future, the stepper motor market is projected to reach $6.14 billion by 2027, growing at a CAGR of 6.4% from 2020. This growth is driven by the increasing demand for automation in various sectors, making advanced motor technology an essential facet of modern supply chain management.

The implementation of high-performance stepper motor controllers enhances system precision and efficiency, crucial in industries ranging from manufacturing to logistics. For instance, a study conducted by the International Society of Automation indicates that automation can increase productivity by up to 30%. As companies strive for operational excellence, the transition to advanced motor technologies not only minimizes downtime but also optimizes resource allocation, ultimately leading to a more resilient supply chain. Embracing these innovations positions organizations to better respond to market fluctuations and customer demands in an era defined by rapid change.