10 Essential Tips for Choosing the Right Machine Tool for Your Workshop

When setting up a workshop, selecting the right machine tool can significantly influence both productivity and the quality of work produced. Renowned machine tool expert, Dr. Emily Carter, once stated, “The foundation of any successful workshop lies in the precision and versatility of its machine tools.” This insight highlights the importance of making informed decisions when it comes to choosing the tools that will define your projects and operations.

With a myriad of options available, the selection process can seem overwhelming. Understanding the essential factors that contribute to the functionality and effectiveness of machine tools is crucial. From assessing the specific needs of your projects to considering the types of materials you'll be working with, the choice of machine tool can either propel your workshop to new heights or hinder its potential.

In this article, we present the top five tips for choosing the right machine tool for your workshop. By delving into these essential guidelines, workshop owners and operators alike will be equipped with the knowledge necessary to make decisions that enhance efficiency and ensure the longevity of their investments.

Understanding Your Workshop Needs and Space Limitations

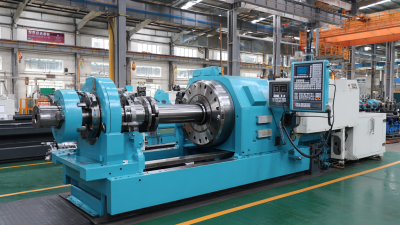

When selecting the right machine tool for your workshop, a crucial first step is understanding your specific needs and the limitations of your workspace. Assess the types of projects you typically undertake, whether they involve wood, metal, or composites. This understanding will guide you in identifying the essential features required in a machine tool, such as power, precision, and versatility. It is also important to consider the size and complexity of the tool, as this will affect not only your workflow but also the overall organization of your workshop.

Space limitations are another key factor in your decision-making process. Evaluate the dimensions of your workshop and the available floor space, ensuring that the machine tool fits comfortably without overcrowding your workspace. Think about the layout, including access to power sources and the movement of materials in and out of the area. Opt for compact tools that provide functionality without sacrificing space, and consider multi-functional machines that can perform various tasks while reducing the need for multiple tools. This thoughtful approach to workshop needs and space management will lead to a more efficient and productive environment.

Evaluating Different Machine Tool Types and Their Functions

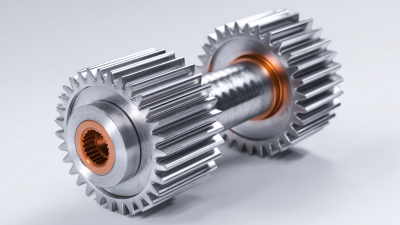

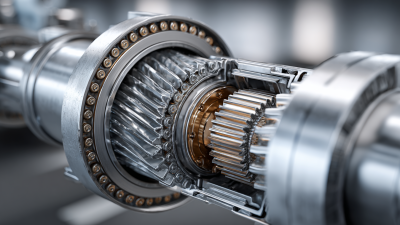

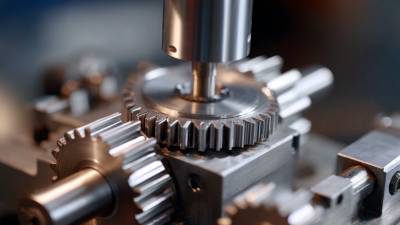

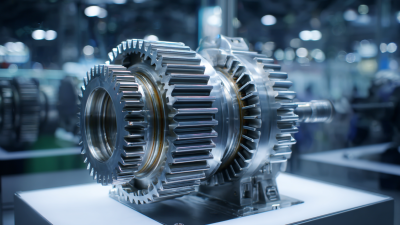

When selecting the right machine tool for your workshop, evaluating the different types of machine tools and their functions is crucial. Each tool has specific applications and benefits that cater to various machining needs. For instance, traditional lathes and milling machines are excellent for precision work in shaping and cutting materials. In contrast, actuating tools can significantly enhance machining capabilities by enabling additional functionalities like turning operations, thus providing flexibility for complex projects.

Moreover, considering advancements in machine learning and technology can influence the choice of machine tools in modern workshops. For example, AI-enabled machine tools are becoming increasingly prevalent, allowing for smarter operations and predictive maintenance. These tools not only improve efficiency but also contribute to better quality control in the manufacturing process. Understanding the distinct roles of each tool type—be it for cutting, shaping, or more advanced automated tasks—will empower workshop owners to make informed decisions that align with their specific operational requirements.

Machine Tool Types and Their Functions

Assessing Budget Constraints and Long-Term Investment Value

When selecting machine tools for your workshop, understanding budget constraints alongside long-term investment value is crucial. According to a 2021 report by Technavio, the global machine tool market is expected to grow by USD 4.22 billion between 2021 and 2025 at a compound annual growth rate (CAGR) of 3%. This growth highlights the necessity of making informed purchasing decisions that align with both immediate financial resources and future production goals.

Assessing your budget is the first step in this process. It’s essential to define not only the initial purchase cost but also the ongoing operational expenses, including maintenance, tooling, and potential downtime. Data from the American Machine Tool Distributors’ Association reveals that a well-maintained machine tool can provide a return on investment (ROI) of up to 300% over its lifespan. Therefore, while a higher upfront cost may seem daunting, investing in quality tools can significantly enhance productivity and profitability in the long run. Balancing initial expenditures with sustained operational savings can protect your bottom line while ensuring your workshop is equipped for future growth.

Researching Brand Reputation and Customer Reviews

When selecting the right machine tool for your workshop, researching brand reputation and customer reviews is paramount. According to a 2022 report by the Association for Manufacturing Technology (AMT), over 60% of manufacturing professionals prioritize brand trust as a critical factor in their purchasing decisions.

A reputable brand often signifies not only quality craftsmanship but also robust support and maintenance services, which are vital for the longevity of the machinery.

Customer reviews can provide invaluable insights into the practical performance of machine tools. A study published in the Journal of Manufacturing Science and Engineering highlighted that 78% of purchasers considered user feedback more influential than product specifications. Detailed reviews can reveal common issues, ease of use, and overall satisfaction levels.

Platforms such as Trustpilot and industry-specific forums often showcase verified user experiences, helping potential buyers make informed decisions. Thus, taking the time to analyze brand reputation alongside customer feedback can significantly impact the effectiveness and reliability of the tools you choose for your workshop.

Considering Maintenance Requirements and Spare Parts Availability

When selecting the right machine tool for your workshop, one crucial aspect to consider is maintenance requirements and the availability of spare parts. According to the 2022 State of the Machine Tool Industry report, approximately 30% of machine tool failures can be attributed to inadequate maintenance. By prioritizing tools that are easy to maintain, you can significantly reduce downtime and extend the lifespan of your equipment. It's essential to choose machines designed with user-friendly access to components for routine checks and repairs.

Tip: Always assess the manufacturer's recommendations for maintenance intervals and procedures. Look for machines that come with detailed guides and support to help you better understand their upkeep.

Availability of spare parts is another vital consideration; delays in obtaining replacement parts can halt production and lead to financial losses. Research indicates that workshops using mainstream brands experience a 25% faster turnaround in parts availability compared to lesser-known manufacturers. Therefore, invest in machine tools from reputable suppliers with an established network for spare parts.

Tip: Before making a purchase, inquire about the local availability of spare parts and any long-term support included with the tool, ensuring that you will not face delays during critical repairs.