| 1 |

Assess the production quality standards. |

Check for ISO certifications. |

24/7 support availability. |

| 2 |

Evaluate the range of machine tools offered. |

Longstanding industry presence. |

Live chat options for quick assistance. |

| 3 |

Consider customization possibilities. |

Positive customer reviews. |

Responsible warranty offerings. |

| 4 |

Inspect machine tooling accuracies. |

Recommendations from peers. |

On-site training availability. |

| 5 |

Review safety features and standards. |

Industry awards and accolades. |

Technical support documentation. |

| 6 |

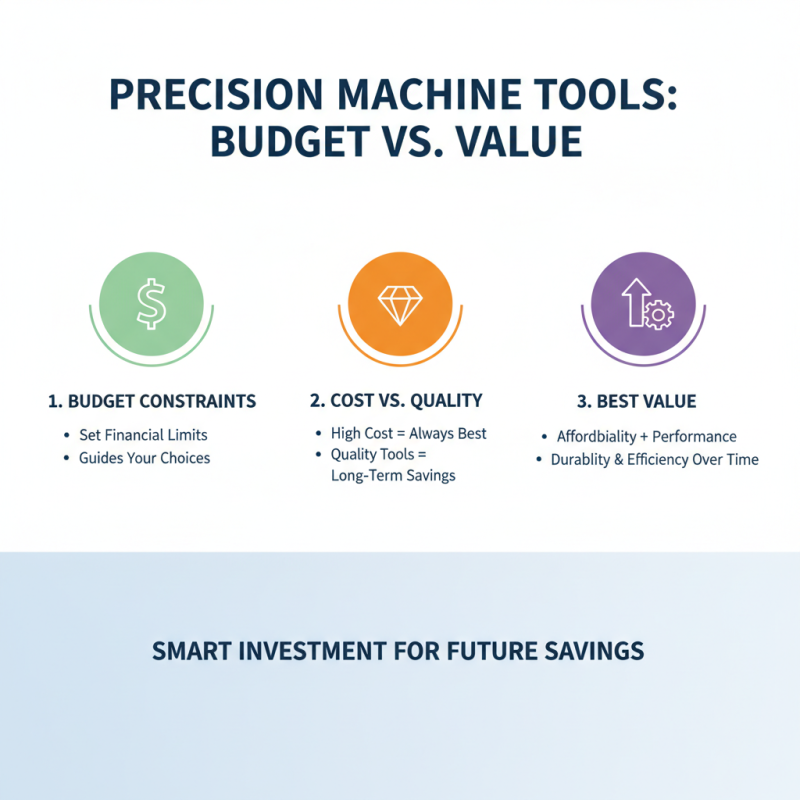

Assess the total cost of ownership. |

Longevity of machine performance. |

Ease of obtaining spare parts. |

| 7 |

Understand the energy consumption rates. |

Client testimonials on longevity. |

Follow-up service response time. |

| 8 |

Ensure compatibility with existing tools. |

Market presence duration. |

Comprehensive FAQs on the website. |

| 9 |

Evaluate the training and resource availability. |

Conformity to recent innovations. |

Accessibility of customer service. |

| 10 |

Make time for adequate evaluation and selection. |

Proven track record in the market. |

User-friendly return policies. |