Exploring Gear Reducers Innovations at China’s 138th Canton Fair 2025: Industry Insights

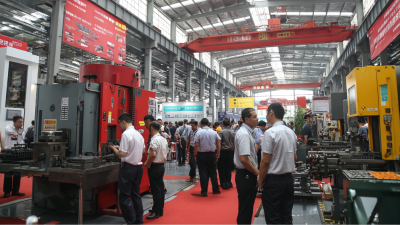

As the global economy continues to pivot towards automation and enhanced efficiency, gear reducers have emerged as a critical component in various industrial applications, ranging from robotics to automotive industries. According to a recent report by MarketsandMarkets, the gear reducer market is expected to grow from USD 19.2 billion in 2020 to USD 25.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.8%. The upcoming 138th Canton Fair in 2025 presents a significant opportunity to showcase the latest innovations in gear reducers, drawing attention from industry professionals keen on leveraging advanced technologies to improve operational efficiencies. At this prestigious event, manufacturers and suppliers from around the globe will converge to exchange insights, explore cutting-edge developments, and identify potential collaborations that can drive the gear reducer industry forward in an increasingly competitive landscape.

Innovations in Gear Reducers: Key Trends to Watch at Canton Fair 2025

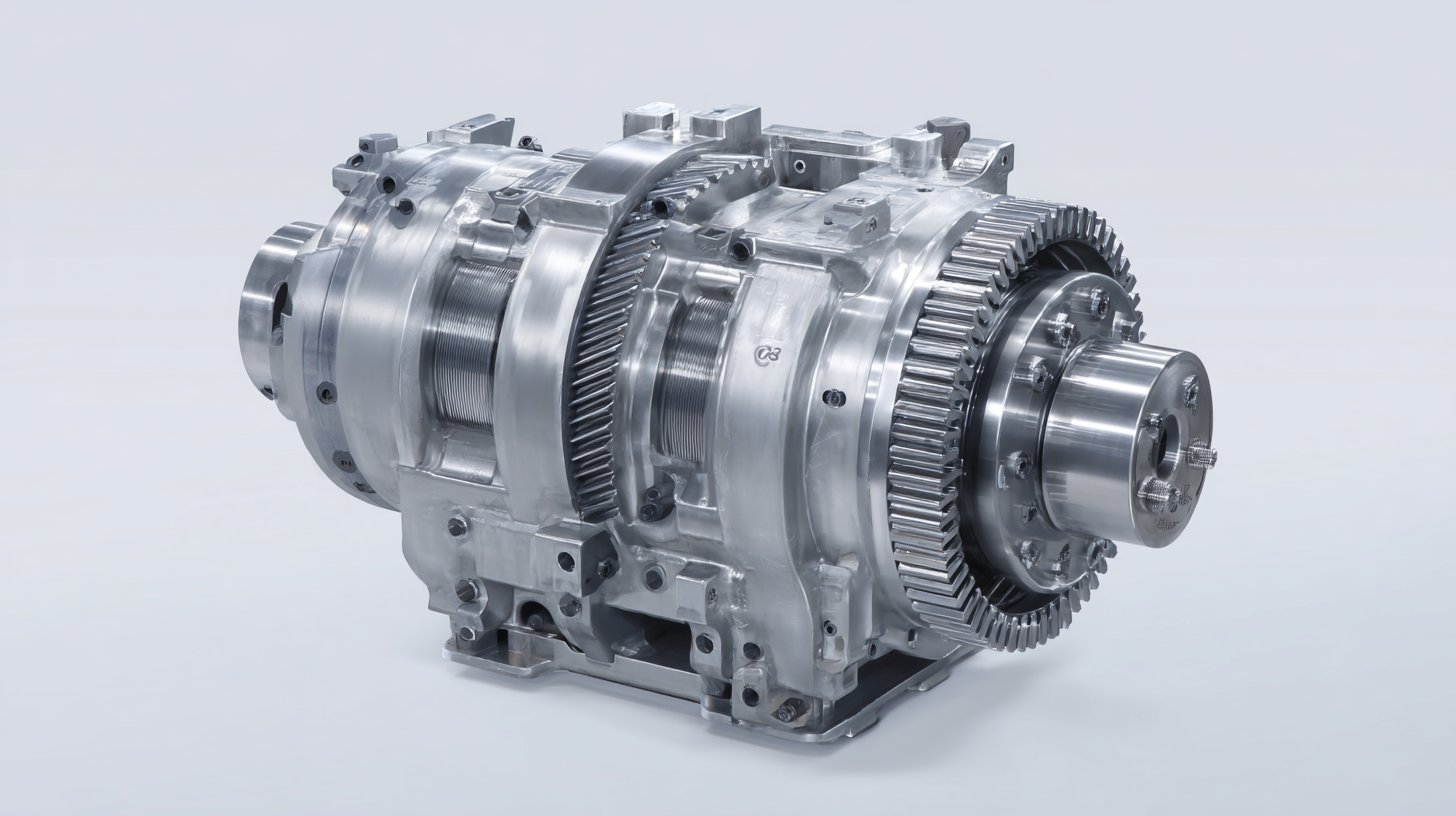

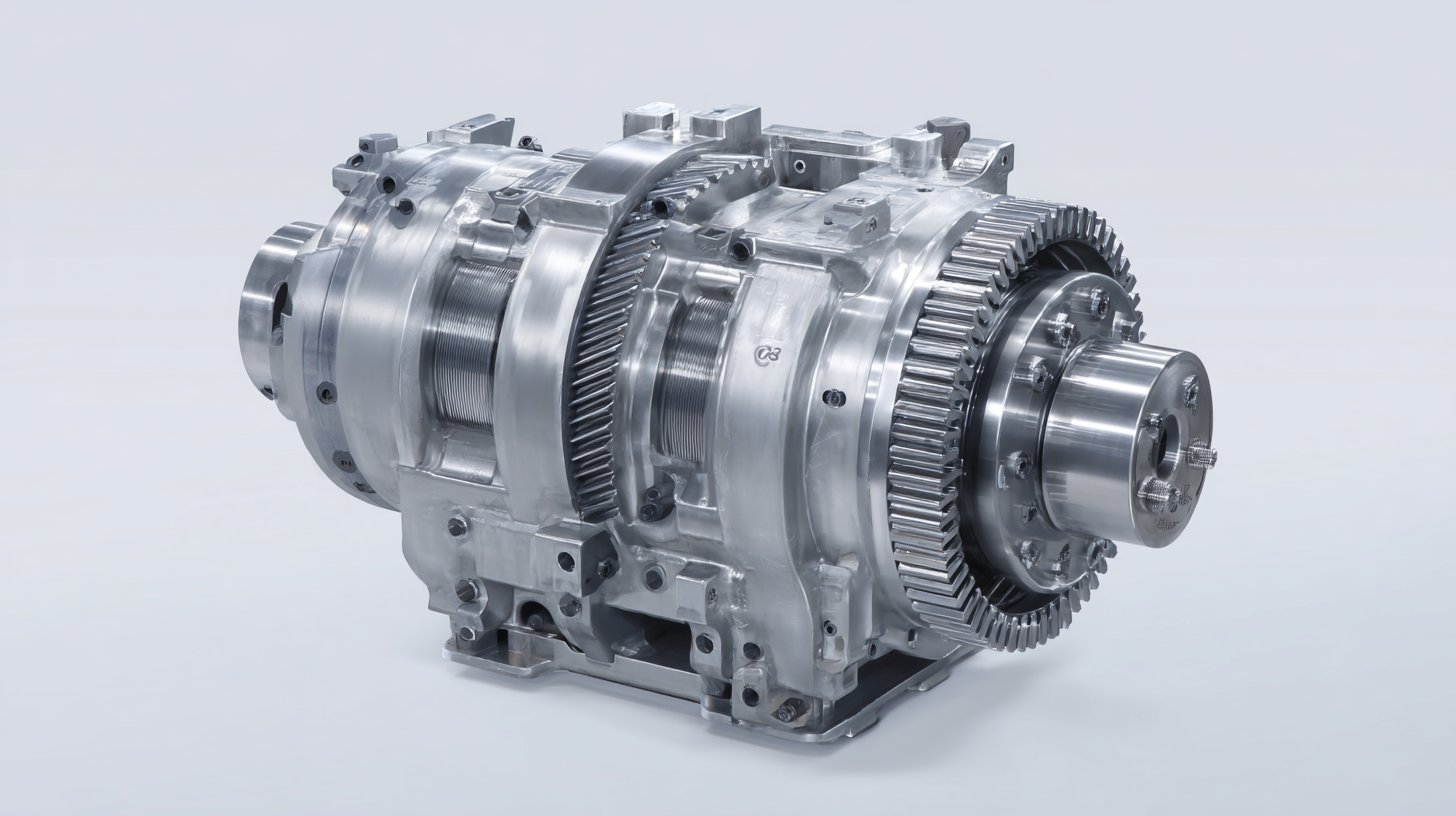

As the 138th Canton Fair approaches in 2025, the spotlight will be on the latest innovations in gear reducers, a crucial component in numerous industrial applications. One significant trend to anticipate is the integration of smart technology in gear reducer systems. With the advent of Industry 4.0, manufacturers are increasingly prioritizing connectivity and automation, leading to the development of gear reducers that can communicate with other machines and systems. This innovation allows for improved monitoring of performance and predictive maintenance, ultimately enhancing operational efficiency in various industries.

Another notable trend is the shift towards sustainable and energy-efficient gear reduction solutions. Manufacturers are responding to environmental concerns by developing gear reducers that minimize energy loss and reduce carbon footprints. Innovations such as advanced materials and optimized designs contribute to lower energy consumption while maintaining high performance. At the Canton Fair, attendees will likely witness products that not only showcase exceptional engineering but also align with global sustainability goals, driving the industry towards a greener future.

Impact of Industry 4.0 on Gear Reducer Technologies and Applications

At the 138th Canton Fair in 2025, the spotlight will be on gear reducers, showcasing how Industry 4.0 is reshaping their technologies and applications. The integration of advanced technologies such as AI and IoT in manufacturing processes is enhancing the efficiency and precision of gear reducers. By leveraging real-time data analytics and automation, manufacturers are able to optimize the performance of gear reducers, ensuring they meet the increasingly complex demands of modern machinery.

The impact of Industry 4.0 extends beyond mere efficiency gains; it fosters greater adaptability in production processes, allowing manufacturers to quickly adjust to market changes and consumer preferences. This adaptability also contributes to environmental sustainability, as technologies promote more resource-efficient production methods. Moreover, as companies invest in Industry 4.0 tools, they are opening the door to innovations that not only enhance product quality but also redefine the entire supply chain, underscoring the disruptive yet positive nature of these advancements in the gear reducer industry.

Market Growth Projections: Assessing the Gear Reducer Industry's Future until 2030

As the gear reducer industry continues to evolve, market growth projections suggest a promising future until 2030, driven by increased demand in various sectors such as automotive, machinery, and renewable energy. According to a recent report by Market Research Future, the global gear reducer market is projected to grow at a compound annual growth rate (CAGR) of approximately 6.5% during the forecast period. This growth is fueled by innovations in gear design and materials, which enhance efficiency and reduce manufacturing costs, positioning companies for competitive advantage in the expanding market.

Tips for industry stakeholders include investing in research and development to harness the latest technological advancements, particularly in smart and energy-efficient gear systems. Additionally, exploring partnerships with technology providers can foster innovation and lead to the development of more robust solutions tailored to specific industrial needs. Companies should also focus on sustainability, as eco-friendly products are increasingly appealing to customers and can open new market opportunities.

As we approach the 138th Canton Fair, showcasing innovations in gear reducers will be vital for businesses looking to establish themselves in the global market. Engaging with industry experts and potential clients at the fair can provide valuable insights into emerging trends and customer preferences, ensuring that companies remain at the forefront of this dynamic industry landscape.

Sustainability in Gear Reducers: Eco-Friendly Innovations Showcased at the Fair

At the 138th Canton Fair in 2025, innovation and sustainability took center stage in the gear reducer industry. With eco-friendly practices becoming imperative, several exhibitors showcased cutting-edge gear reducer technologies designed to minimize environmental impact. These innovations include the use of recyclable materials in production processes and advanced designs that significantly improve energy efficiency. By focusing on reducing energy consumption and emissions, manufacturers are not only enhancing performance but also contributing to a greener future.

Moreover, the fair highlighted companies committed to sustainable manufacturing techniques. Many participants demonstrated their latest gear reducer models, which incorporate features aimed at longevity and reduced waste. Innovations such as biodegradable lubricants and modular designs that allow for easier repairs and recycling were prominent. The push for sustainability in gear reducers is indicative of a broader trend within the industrial sector, where businesses are increasingly prioritizing eco-friendly solutions. This commitment not only aligns with global sustainability goals but also resonates with buyers looking for responsible options in their purchasing decisions.

Comparative Analysis: China’s Gear Reducer Export Trends Against Global Markets

At the 138th Canton Fair in 2025, innovative developments in gear reducers captured significant attention, unveiling a competitive edge in international markets. China’s gear reducer manufacturers are showing evolving design techniques and advanced manufacturing processes, which contribute to increased efficiency and performance. This is crucial for their positioning in global markets, particularly against competitors in Europe and North America, where product standards have traditionally been higher.

As we analyze gear reducer export trends from China, it's evident that shifts in global demand are influencing production strategies. Countries are seeking to capitalize on automation and energy efficiency, driving companies to enhance their offerings. One notable trend is the rise of customized gear reducers tailored to specific industry needs, signaling a move towards more specialized manufacturing.

**Tip:** Companies looking to enter the gear reducer market should focus on understanding regional demand and regulatory standards to enhance competitiveness. Collaborating with local distributors can also help navigate the complexities of international trade. Engaging in trade shows like the Canton Fair is essential for networking and gaining insights into emerging technologies and market trends.

Exploring Gear Reducers Innovations at China’s 138th Canton Fair 2025: Industry Insights

| Region |

Export Volume (Units) |

Growth Rate (%) |

Market Share (%) |

Average Price (USD) |

| North America |

20,000 |

5.2 |

30 |

150 |

| Europe |

25,000 |

4.7 |

35 |

145 |

| Asia |

18,000 |

6.0 |

25 |

160 |

| South America |

12,000 |

3.5 |

10 |

130 |

| Africa |

8,000 |

4.0 |

5 |

120 |