A Comprehensive Guide to Selecting the Best Ac Servo Motor for Your Industry Needs

In today's rapidly evolving industrial landscape, selecting the right Ac Servo Motor is crucial for optimizing performance and ensuring operational efficiency across various applications. This guide aims to provide a comprehensive overview of the diverse types of Ac Servo Motors available, their unique characteristics, and the specific industry needs they cater to. Whether you are in manufacturing, robotics, or any sector requiring precise motion control, understanding the benefits and appropriate use cases of each motor type is essential for making informed decisions. By delving into the features and advantages of different Ac Servo Motors, this article will equip you with the knowledge necessary to choose the best product for your unique requirements, ultimately enhancing productivity and reliability in your operations.

Key Factors to Consider When Choosing an AC Servo Motor for Your Application

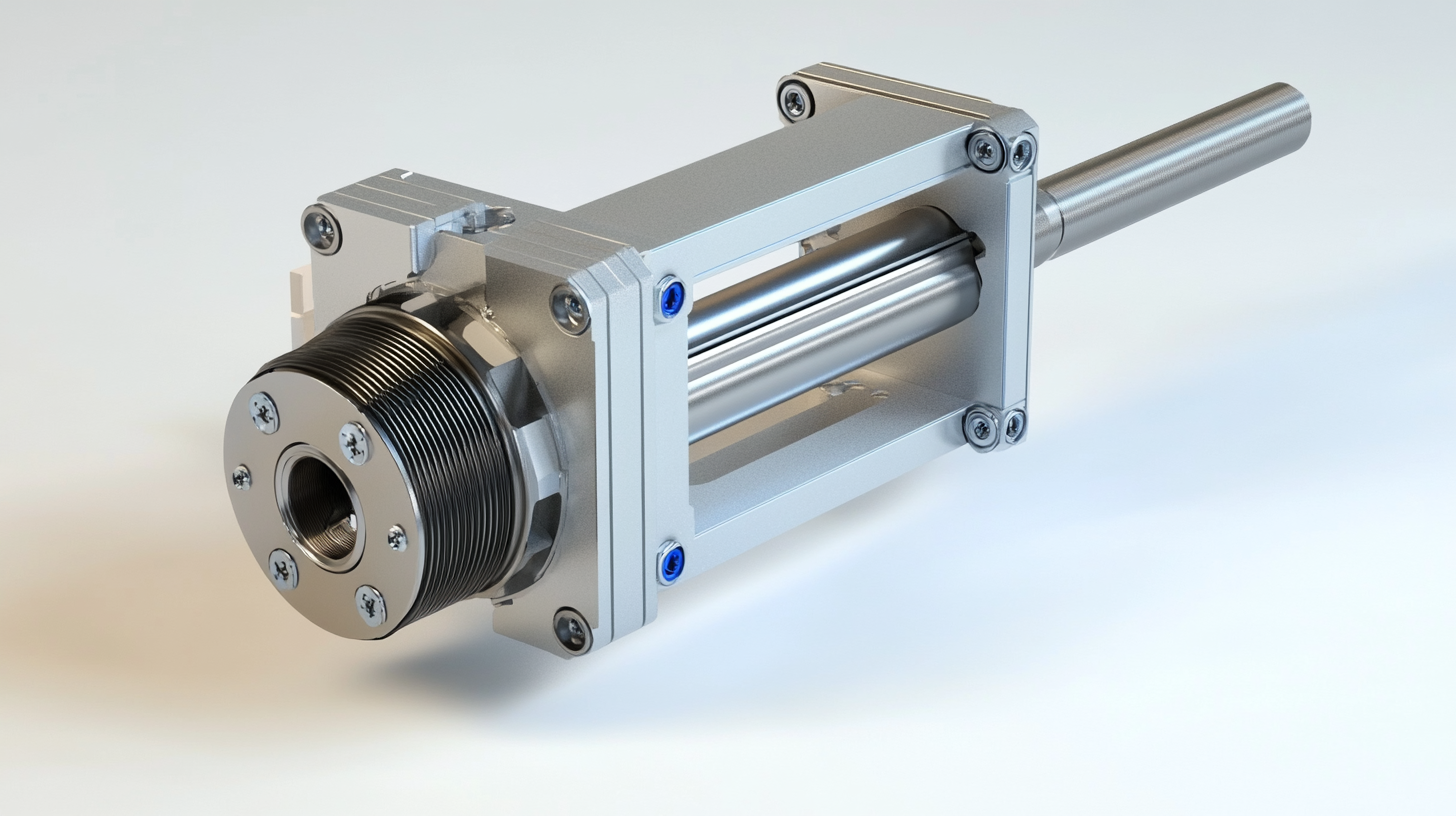

When selecting an AC servo motor for your specific industrial application, several key factors should be carefully evaluated to ensure optimal performance and efficiency. One of the primary considerations is the torque and speed requirements of your application. Different applications demand varying torque levels; therefore, examining the load characteristics and peak demands is crucial. Additionally, the speed range must align with the operational needs, as certain tasks may require high-speed operations while others prioritize torque over speed.

Another important aspect to take into account is the motor's size and mounting configuration. It's essential to ensure that the selected servo motor fits within your existing machinery and complies with space constraints. Compatibility with your control system is also vital; choosing a motor that integrates seamlessly with your existing drives and controllers can significantly enhance overall efficiency. Lastly, consider environmental factors such as temperature and humidity, which can affect the motor's performance and longevity. By addressing these key factors, you can select an AC servo motor that not only meets your current needs but is also adaptable for future demands.

A Comprehensive Guide to Selecting the Best Ac Servo Motor for Your Industry Needs

| Parameter | Description | Importance |

|---|---|---|

| Torque | The rotational force output of the motor. | High |

| Speed | The rate at which the motor can operate. | High |

| Feedback Type | The type of sensor used for position and speed feedback. | Medium |

| Power Rating | The electrical power consumption of the motor. | High |

| Size and Weight | Physical dimensions and weight of the motor. | Medium |

| Operating Environment | Conditions such as temperature, humidity, and exposure to dust. | High |

| Control Method | Type of control technology used (PWM, analog, etc.). | Medium |

Understanding the Different Types of AC Servo Motors Available in the Market

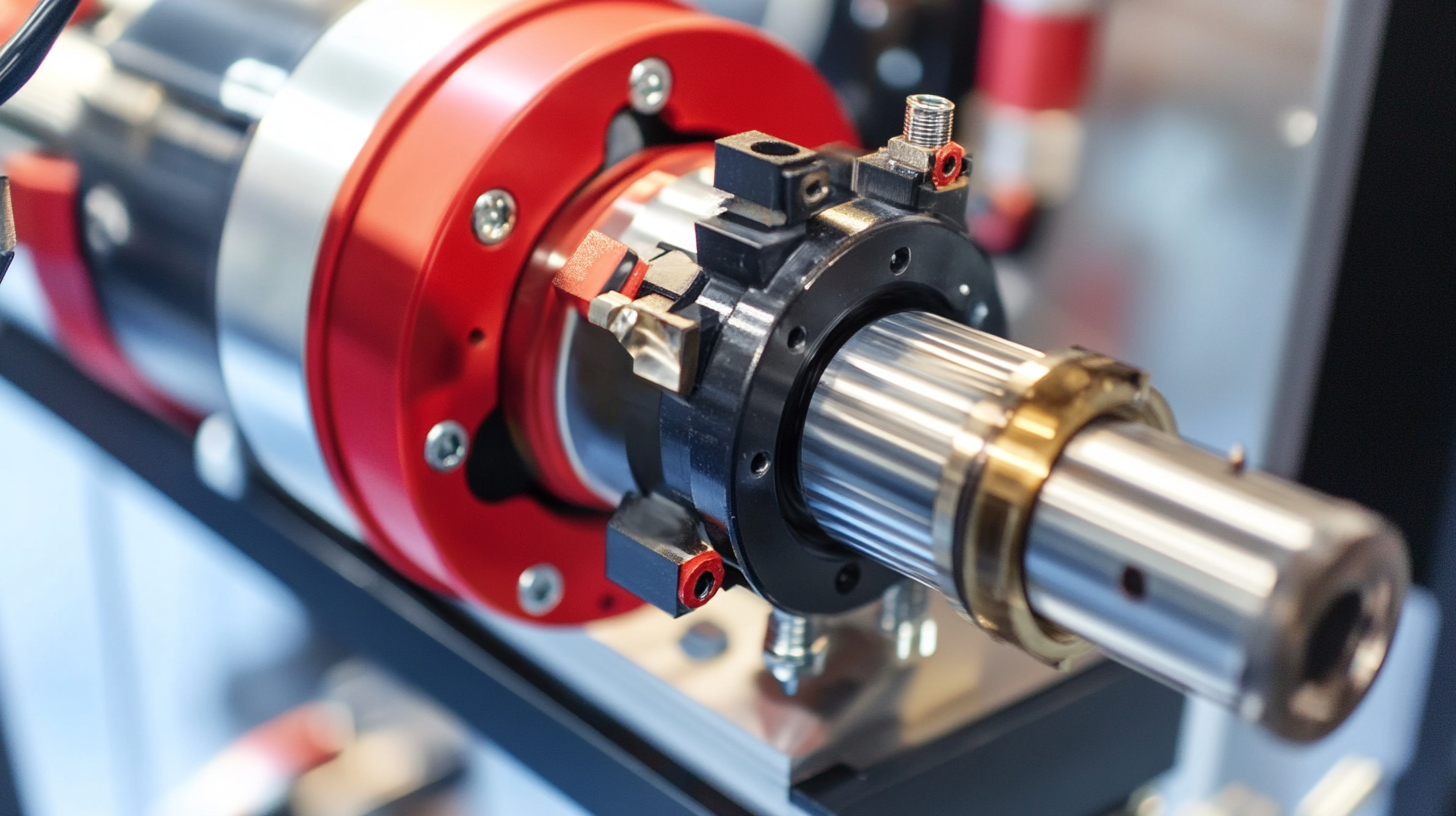

When selecting an AC servo motor for industrial applications, understanding the various types available in the market is crucial. AC servo motors generally fall into three main categories: synchronous, asynchronous, and stepper motors. Synchronous motors are known for their precision and efficiency, making them ideal for high-performance applications. In contrast, asynchronous motors, or induction motors, offer robust performance with lower cost, which can be beneficial in less precision-demanding tasks. Stepper motors provide a good solution for applications requiring precise incremental movements, though they may not meet the speed and torque performance of synchronous models.

According to a recent industry report by Research and Markets, the global AC servo motor market is expected to grow at a CAGR of 6.2% from 2021 to 2026, fueled by advancements in automation technologies. This growth emphasizes the importance of selecting the right type of motor. For instance, industries focusing on robotics, CNC machinery, and conveyor systems are increasingly adopting synchronous motors due to their high positional accuracy and dynamic response. Furthermore, the automotive sector has shown a marked preference for induction motors, leveraging their durability and performance in manufacturing processes. Understanding these distinctions aids businesses in making informed decisions that align with their operational requirements and budget constraints.

A Comprehensive Guide to Selecting the Best AC Servo Motor for Your Industry Needs

This chart represents the key characteristics of AC Servo Motors, showcasing torque, speed, precision, efficiency, and cost. These metrics are crucial for selecting the best servo motor tailored to your industrial needs.

How to Calculate the Required Torque and Speed for Your Industry Needs

When selecting an AC servo motor for your industrial applications, understanding how to calculate the required torque and speed is essential. The first step is to determine the load requirements of your machinery. You need to assess both the static and dynamic loads that the motor will encounter. The static load refers to the constant force required to keep components in motion, while the dynamic load accounts for forces during acceleration and deceleration. By calculating these loads, you can ensure that the motor selected will be capable of handling the demands of your specific application.

Next, it’s crucial to consider the speed requirements. The motor's speed must be aligned with the operational speed of the machinery to achieve optimal performance. This involves calculating the necessary RPM (revolutions per minute) based on the application’s needs, such as the type of machinery and the product being processed. Additionally, factoring in the required acceleration time and the distance over which the load will move will help in fine-tuning your motor selection. By carefully analyzing torque and speed together, you can ensure that the AC servo motor you choose will meet the performance criteria of your industry efficiently.

Evaluating the Control Systems Compatible with Your AC Servo Motor Choice

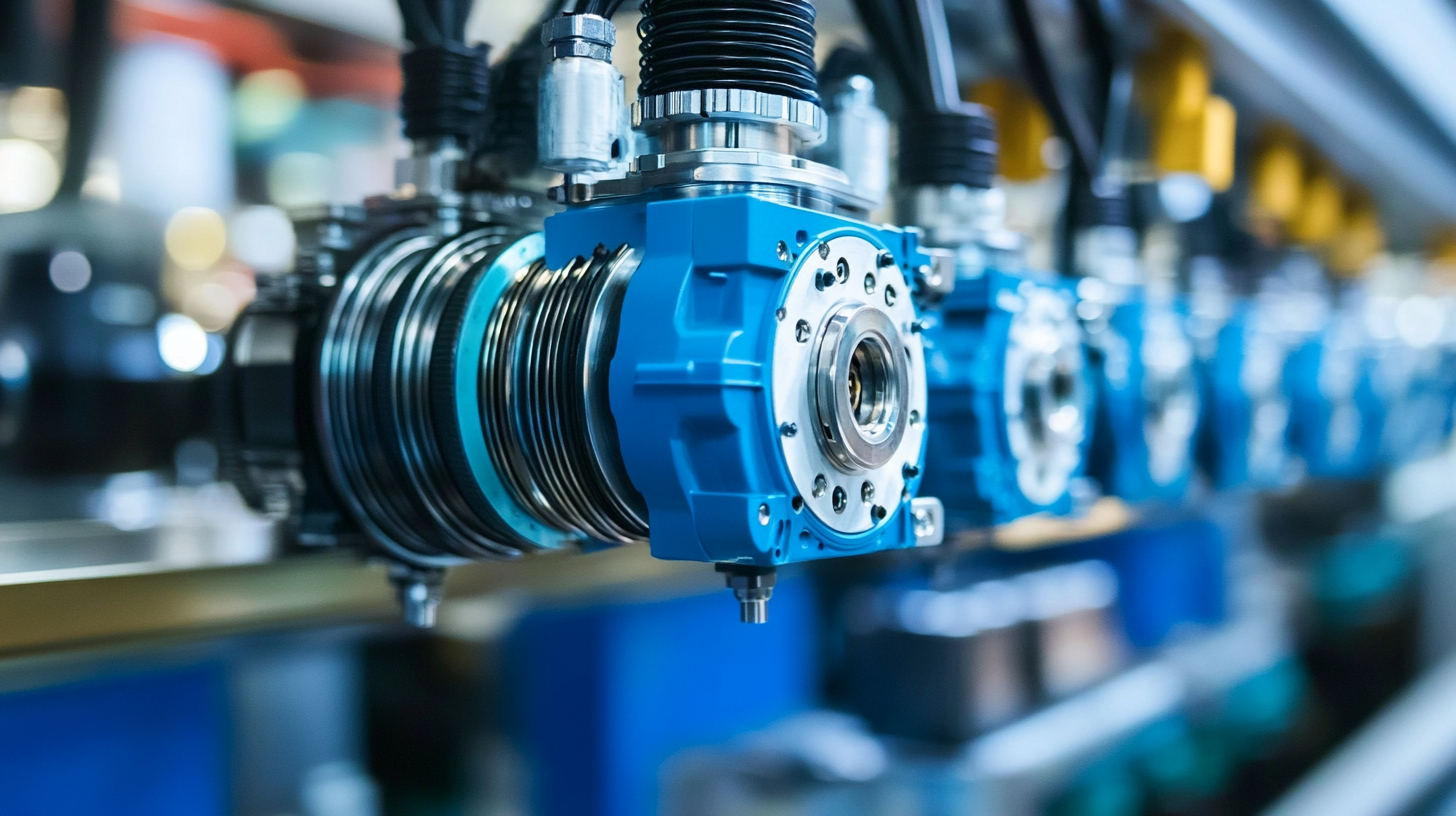

When selecting an AC servo motor, understanding the compatibility of control systems is essential for optimizing performance in industrial applications. According to a report by MarketsandMarkets, the global servo motors and drives market is projected to grow from USD 10.9 billion in 2020 to USD 15.2 billion by 2025, indicating the increasing importance of efficient control solutions. The choice of control system can significantly influence not only the responsiveness and accuracy of the motor but also overall operational efficiency.

Different control systems, such as PWM (Pulse Width Modulation) and vector control, cater to various application needs. For instance, vector control systems provide superior torque and speed regulation, making them ideal for high-precision tasks, while PWM controls are more suited for simpler applications with less stringent performance demands. A study from Grand View Research highlights that the market for advanced motion control systems is expected to experience a CAGR of 7% from 2021 to 2028, emphasizing the growing need for businesses to align their AC servo motor selections with state-of-the-art control technologies to remain competitive. Understanding these dynamics is crucial for industries aiming to enhance their automation capabilities.

Top Brands and Specifications to Look for in High-Performance AC Servo Motors

When selecting high-performance AC servo motors for industrial applications, it’s essential to consider both reputable brands and key specifications. Leading manufacturers such as Siemens, Mitsubishi Electric, and Yaskawa have consistently demonstrated their commitment to innovation and reliability. According to a recent report by Research and Markets, the global AC servo motor market is expected to reach $6.57 billion by 2027, driven by the increasing demand for automation in various sectors, including manufacturing and robotics.

Key specifications to look for when choosing an AC servo motor include torque output, speed range, and encoder resolution. A torque output that meets the application’s requirements is crucial, as it directly affects the motor’s performance in dynamic environments. For instance, motors with high-resolution encoders can provide precise control, improving overall system efficiency. Additionally, speed range considerations ensure that the selected motor can operate effectively under varying load conditions. Industry data highlights that systems using high-performance AC servo motors can achieve a 15-30% improvement in energy efficiency compared to conventional motors, showcasing the impact of selecting the right specifications and brands on operational success.