The Ultimate Guide to Selecting the Best Electric Motor: Insights and Industry Data You Can't Miss

In today's rapidly evolving industrial landscape, selecting the right Electric Motor is crucial for optimizing efficiency and performance. According to a recent report by the International Energy Agency (IEA), electric motors account for approximately 45% of global electricity consumption, emphasizing their significance in both energy savings and operational costs. The growth of automation and electrification across various sectors, including manufacturing and transportation, has increased the demand for high-performance Electric Motors, projected to reach $150 billion by 2025, as highlighted by various market analyses. However, with an array of options available, businesses face challenges in determining the most suitable motor type for their specific applications. This guide aims to provide insights and critical industry data that will help you navigate common problems associated with different types of Electric Motors, ensuring informed decision-making in your procurement process.

Key Factors to Consider When Choosing an Electric Motor for Your Application

When selecting an electric motor for your application, several key factors must be considered to ensure optimal performance and efficiency. One of the most critical determinants is energy efficiency, as research indicates that a significant majority of businesses prioritize this aspect in their purchasing decisions. An energy-efficient motor not only reduces operational costs but also supports sustainability goals, making it a vital consideration for modern applications, particularly in industries such as electric vehicles.

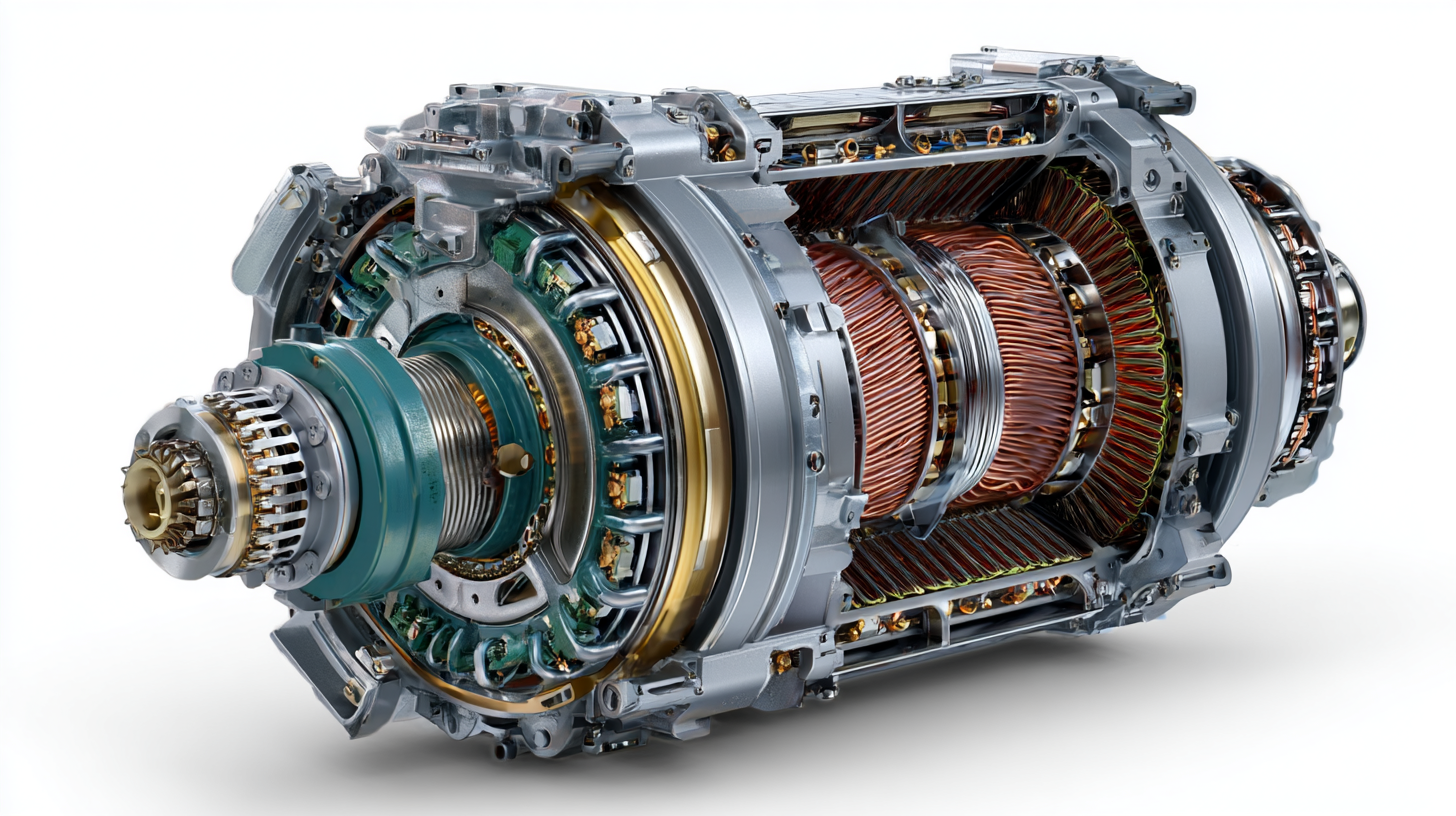

Another important factor is the specific requirements of your application. Different industries may necessitate unique motor designs, such as high power density for aircraft electrification or robust features for automation processes. Understanding your application will guide you in selecting the right motor type—be it induction, brushless, or another variant—that can handle the operational demands effectively.

**Tips:** Always perform a thorough thermal analysis of your motor choice, as effective thermal management is crucial for maintaining performance and extending motor lifespan. Additionally, consider the material choices during the design phase to enhance efficiency and sustainability. Finally, keep in mind that proper maintenance strategies can significantly impact the reliability and longevity of your electric motors, so factor in service capabilities and support when making your selection.

Understanding Different Types of Electric Motors: Pros and Cons

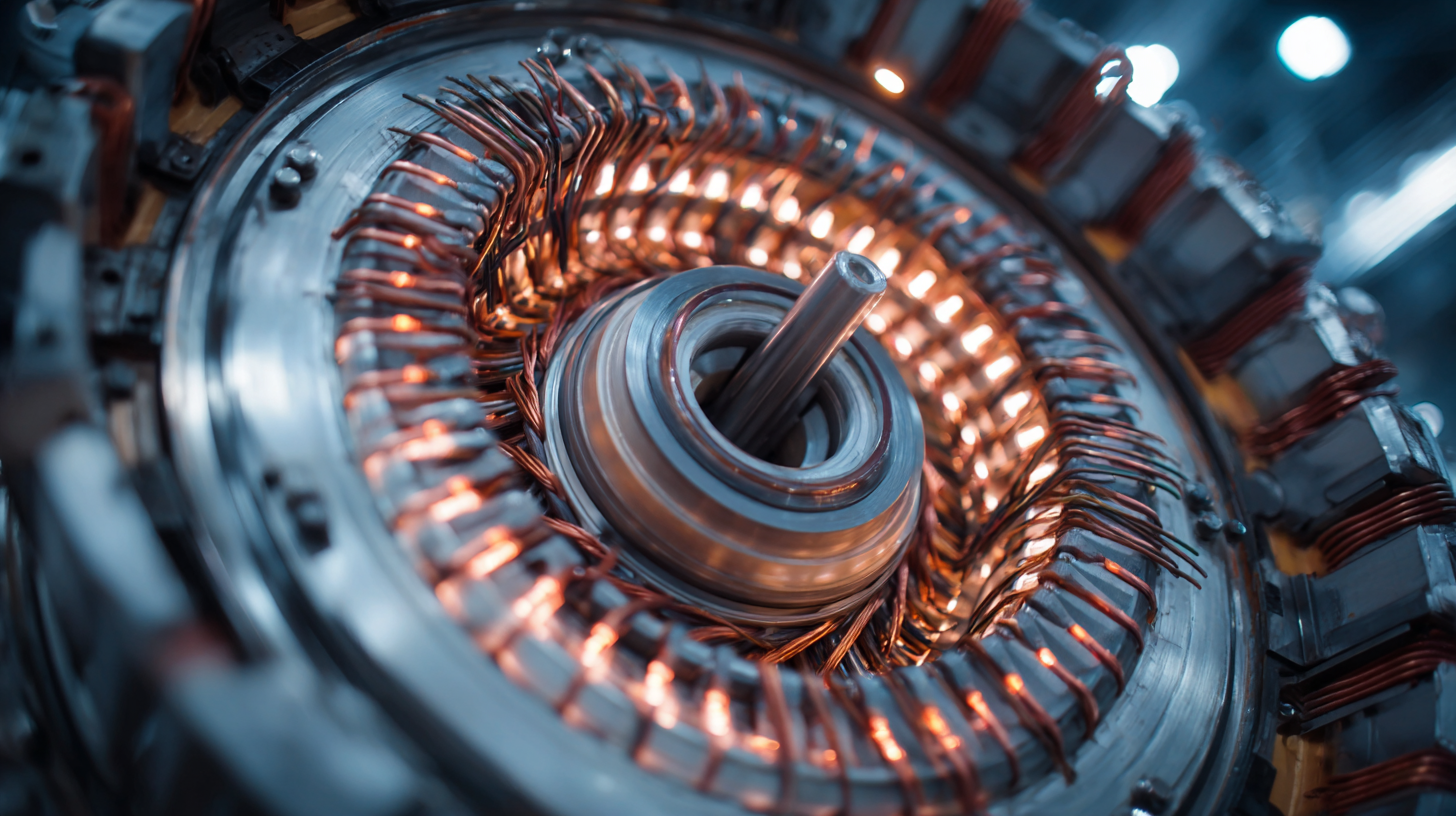

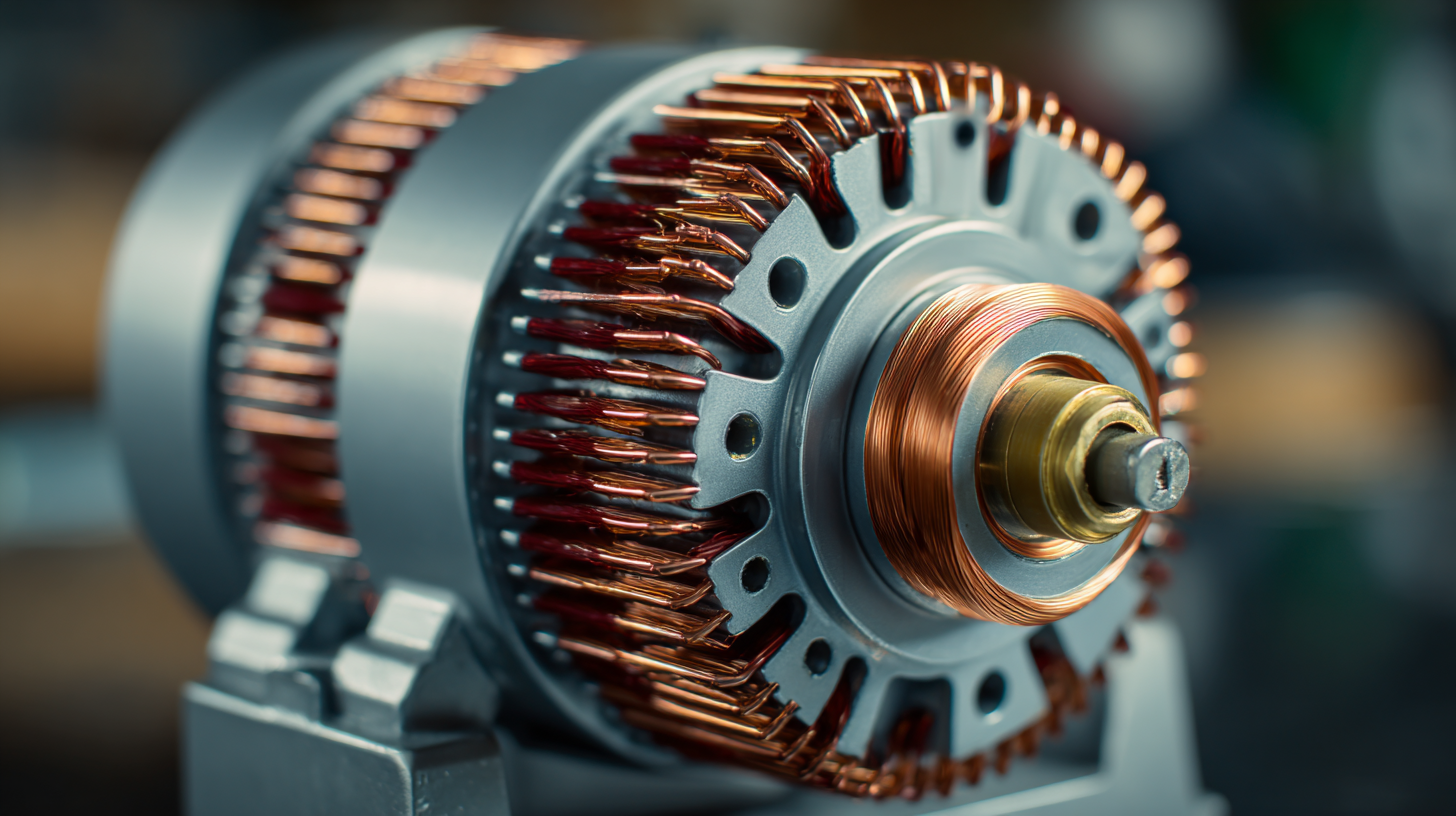

When selecting the best electric motor, understanding the various types and their respective advantages and disadvantages is crucial. Electric motors can be categorized primarily into brushed and brushless types. Brushed motors are known for their simplicity and cost-effectiveness, making them a common choice for small applications. However, they typically have a shorter lifespan due to wear on the brushes. In contrast, brushless motors are more efficient and require less maintenance, making them ideal for high-performance applications, despite their higher initial cost.

Another important aspect to consider is the application of the electric motor in different vehicles, especially in the rapidly evolving electric vehicle market. For instance, in electric trucks, the use of powerful motors ensures that these vehicles can handle heavier loads while remaining efficient. Additionally, the rise of technology such as wheel hub motors is revolutionizing the electric vehicle sector by simplifying designs and enhancing performance. Understanding these variables can have a significant impact on the choice of electric motor, helping manufacturers and consumers make informed decisions tailored to their specific automotive needs.

Market Trends and Predictions: Electric Motor Industry Insights for 2025

As we look toward 2025, the electric motor industry is poised for significant growth, driven by emerging market trends and technological advancements. The global outdoor power equipment (OPE) market is projected to increase from $37.36 billion in 2025 to $54.24 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.47%. This growth underscores the rising demand for efficient electric motors in a variety of applications, from landscaping to agriculture.

Another notable segment is the permanent magnet synchronous motor (PMSM) market, which is expected to expand dramatically from $1.936 billion in 2025 to approximately $4.582 billion by 2033, showcasing an impressive CAGR of 11.37%. This acceleration highlights the importance of PMSMs in sectors that prioritize energy efficiency and performance. Additionally, the HVAC systems market in North America is projected to grow from $51.61 billion in 2025 to $75.75 billion by 2032, reflecting the escalating need for innovative electric motor solutions in climate control systems. These trends illustrate the vital role that electric motors will play in shaping the future of various industries.

Essential Technical Specifications to Evaluate in Electric Motors

When selecting the best electric motor for your application, understanding essential technical specifications is crucial. Key factors to evaluate include torque density, efficiency, and operational lifespan. Torque density determines how much torque a motor can produce relative to its size, which is vital for applications requiring compact designs without sacrificing performance. Efficiency impacts energy consumption and operational costs, especially in large systems where electric motors drive processes continuously. A thorough assessment of these specifications can lead to significant savings and enhanced performance.

Moreover, advancements in technology, such as multiphase cascaded H-bridge inverters and in-wheel electric motor designs, are pushing the boundaries of traditional electric motor applications. These innovations enable improved power control and integrate seamlessly with modern electric vehicle architectures. By staying informed about these developments, businesses can make better decisions, ensuring their electric motor solutions are not just effective today, but also future-proof against the rapid pace of technological change in the industry.

The Ultimate Guide to Selecting the Best Electric Motor

| Motor Type | Power Rating (kW) | Voltage (V) | Efficiency (%) | Speed (RPM) | Weight (kg) | Cooling Method |

|---|---|---|---|---|---|---|

| AC Induction Motor | 15 | 400 | 90 | 1500 | 80 | Air-Cooled |

| DC Brushless Motor | 5 | 24 | 85 | 3000 | 20 | Fan-Cooled |

| Stepper Motor | 2 | 12 | 80 | 2000 | 2 | N/A |

| Synchronous Motor | 10 | 480 | 92 | 1800 | 70 | Water-Cooled |

| Permanent Magnet Motor | 12 | 220 | 95 | 3000 | 50 | Air-Cooled |

How to Calculate the Efficiency and Performance Needs of Electric Motors

When selecting the best electric motor for your application, a critical factor to consider is the efficiency and performance needs specific to your requirements. The rising demand for electric powertrains in the automotive industry has led to remarkable advancements, particularly in high-speed motor designs. For instance, recent developments in electric motors have achieved astonishing speeds, with some models reaching up to 30,000 RPM. This performance showcases not only efficiency but also the need for meticulous calculations to ensure that an electric motor meets the performance specifications necessary for success in today's competitive market.

To properly assess efficiency, it’s vital to understand the relationship between motor speed, torque, and power input/output. By analyzing these variables, you can identify the optimal balance that aligns with your operational goals. Additionally, as manufacturers grapple with the challenges of minimizing size while maximizing performance, innovations in materials and design strategies continue to reshape the electric motor landscape. Focused on delivering greater efficiency and diminished energy losses, the new breed of electric motors is not just about speed; it is about harnessing sustainable energy use in the quest for superior automotive performance.