The Definitive Guide to Sourcing the Best Small Stepper Motor Suppliers Worldwide

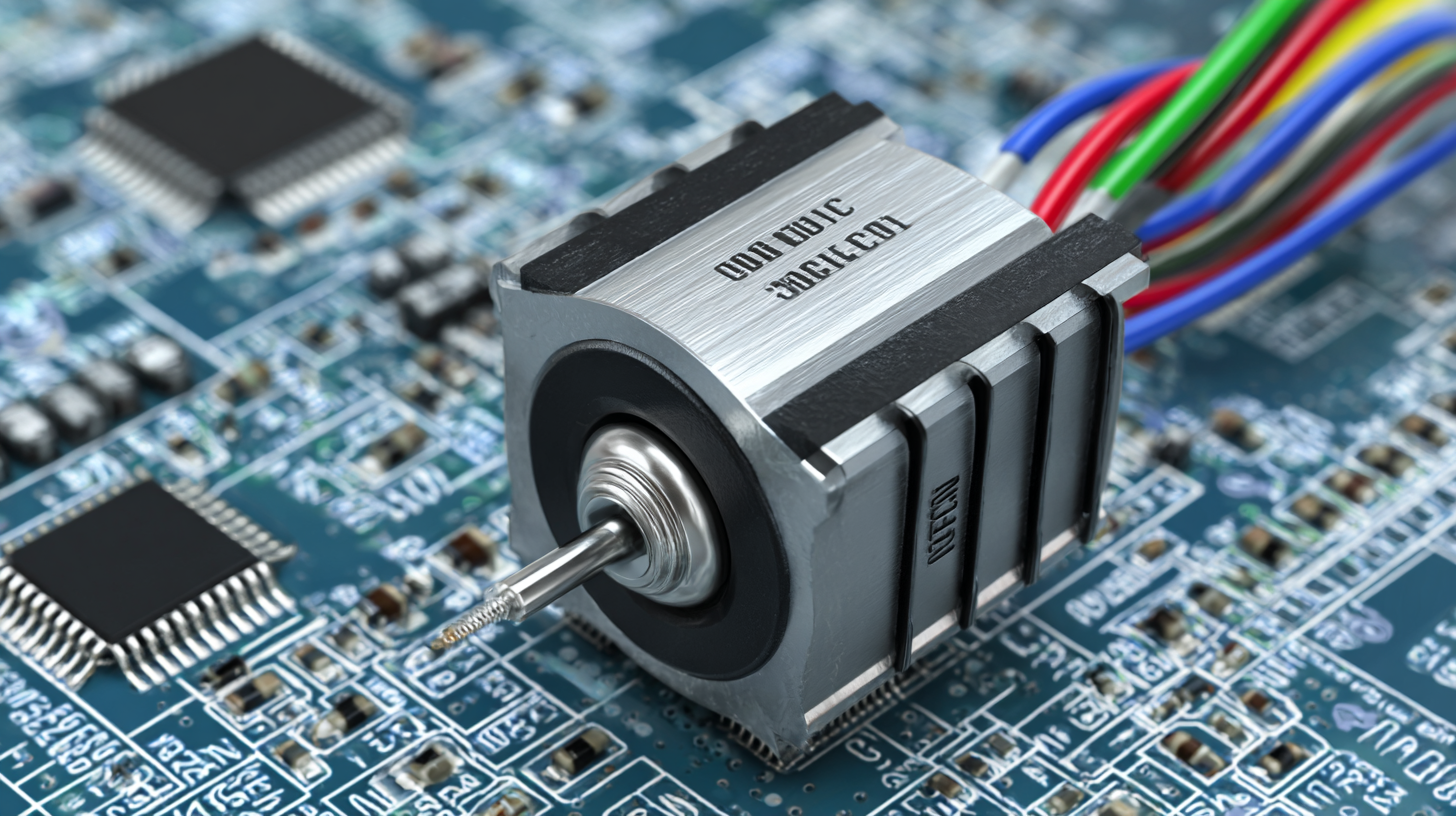

In the ever-evolving landscape of automation and precision engineering, the demand for small stepper motors has surged, driven by advancements in robotics, CNC machinery, and 3D printing applications. According to the latest market research report by Grand View Research, the global stepper motor market is expected to reach USD 9.1 billion by 2025, growing at a CAGR of 6.2%. This significant growth underscores the critical role that small stepper motors play in enhancing efficiency and precision in various industries. As manufacturers seek to optimize performance while reducing costs, sourcing high-quality small stepper motor suppliers becomes paramount. In this definitive guide, we will explore the key factors to consider when comparing suppliers worldwide, ensuring that you find the best fit for your specific application needs.

Identifying Key Characteristics of Quality Stepper Motor Suppliers

When sourcing small stepper motor suppliers, identifying key characteristics that signify quality is essential. Industry trends emphasize that high-quality manufacturing can greatly reduce costs, particularly relevant in sectors like medical devices, where quality control directly impacts compliance and safety. A recent analysis suggests that implementing Total Quality Management (TQM)—a systematic approach to continuous improvement—can lead to significant efficiencies in production. Companies that integrate TQM principles into their manufacturing processes report up to a 30% reduction in errors, thereby ensuring more reliable products.

Furthermore, thorough assessments of suppliers' practices in product lifecycle management (PLM) reveal best practices that enhance integration and reduce risks throughout the supply chain. Key characteristics of suppliers include their commitment to robust quality management methodologies and adherence to international standards. A survey indicated that suppliers employing comprehensive quality checks throughout their production cycles saw a 25% increase in customer satisfaction ratings, bolstering their standing in the competitive marketplace for small stepper motors.

By focusing on these critical characteristics, businesses can ensure they partner with suppliers that not only meet technical specifications but also demonstrate a consistent commitment to quality and innovation.

The Best Small Stepper Motor Suppliers Worldwide

Evaluating Supplier Manufacturing Capabilities and Technologies

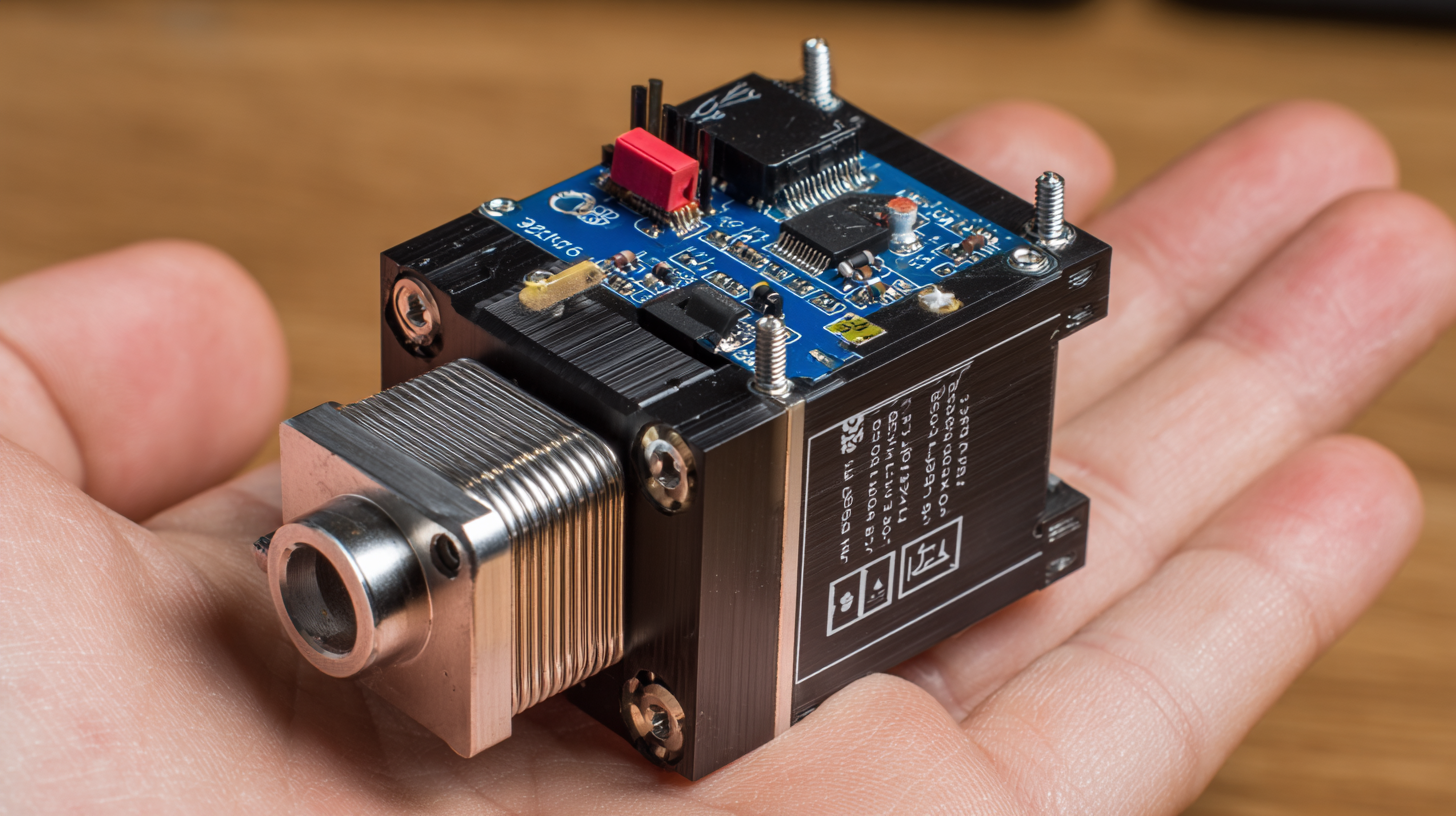

When sourcing small stepper motors, understanding the manufacturing capabilities and technologies of potential suppliers is critical. A thorough evaluation of their production processes can reveal whether a supplier is equipped to meet your specific needs. Look for suppliers that leverage advanced manufacturing techniques such as CNC machining, automated assembly lines, and quality control systems. These technologies not only enhance precision but also increase efficiency, reducing lead times and manufacturing costs.

Additionally, consider suppliers that invest in ongoing research and development. This commitment often reflects a supplier's dedication to innovation and indicates their ability to adapt to new technologies and market demands. A supplier with a robust R&D program is likely to provide products that incorporate the latest advancements in stepper motor technology, ensuring higher performance and reliability. Evaluating these factors will help ensure that you partner with a supplier who can deliver high-quality stepper motors tailored to your project requirements, ultimately contributing to the success of your engineering applications.

Understanding the Importance of Supplier Certifications and Standards

In the realm of small stepper motors, the selection of suppliers is critical, not only for product quality but also to ensure compliance with industry standards. According to the International Organization for Standardization (ISO), over 70% of manufacturing defects can be traced back to supplier performance. If a supplier lacks necessary certifications such as ISO 9001, it raises significant red flags about their quality management systems. These certifications signal a commitment to maintaining quality through established procedures, which can lead to reduced production errors and increased reliability.

Moreover, compliance with industry-specific standards like the RoHS Directive (Restriction of Hazardous Substances) is essential, particularly in electronic components. A report from MarketsandMarkets estimates that the global small stepper motors market will reach $2.2 billion by 2026, emphasizing the growing demand for reliable suppliers who adhere to high standards of safety and compliance. As industries become more competitive, sourcing from certified suppliers not only mitigates risks but also enhances overall operational efficiency, impacting the bottom line positively. Thus, understanding and prioritizing supplier certifications and standards is crucial for businesses looking to thrive in the small stepper motor market.

Exploring Global Markets for Competitive Stepper Motor Sourcing

When it comes to sourcing stepper motors, understanding global markets is crucial for finding competitive suppliers. According to a report by MarketsandMarkets, the global stepper motor market is projected to grow from USD 3.75 billion in 2020 to USD 5.58 billion by 2025, with a compound annual growth rate (CAGR) of 8.2%. This growth is driven by increasing automation in industries such as aerospace, automotive, and consumer electronics, where precision control is critical.

Navigating this international landscape requires identifying suppliers who not only meet quality standards but also offer competitive pricing. Regions known for their manufacturing prowess, like East Asia and parts of Europe, are home to some of the leading stepper motor suppliers. A recent analysis by Grand View Research highlighted that Asia Pacific accounted for over 40% of the stepper motor market share in 2020, emphasizing the importance of leveraging these regional advantages. By strategically sourcing from these global markets, businesses can secure better deals, enhance product quality, and ultimately improve their market position.

The Definitive Guide to Sourcing the Best Small Stepper Motor Suppliers Worldwide

| Supplier Region | Average Price (USD) | Lead Time (Days) | Quality Rating (1-5) | Certifications |

|---|---|---|---|---|

| North America | $200 | 30 | 4 | ISO 9001, CE |

| Europe | $180 | 25 | 5 | ISO 9001, RoHS |

| Asia | $150 | 20 | 4 | ISO 9001, TS 16949 |

| South America | $210 | 40 | 3 | CE |

| Africa | $190 | 35 | 4 | ISO 9001 |

Strategies for Building Lasting Relationships with Stepper Motor Suppliers

Building lasting relationships with stepper motor suppliers is crucial for ensuring a steady supply chain and maintaining product quality. According to a report by MarketsandMarkets, the stepper motor market is expected to reach $4.7 billion by 2025, growing at a CAGR of 4.5%. This growth underscores the increasing demand for high-quality suppliers. However, a successful partnership goes beyond mere transactions; it involves ongoing communication, mutual trust, and shared goals.

Tip 1: Regularly check in with your suppliers and provide feedback on their products and services. This fosters open communication and shows your commitment to a collaborative relationship.

To maximize your supplier relationships, leverage technology to streamline communication. Automated systems and supplier portals can facilitate real-time updates on orders and inventory levels, reducing potential misunderstandings. A study by Supplier Management Solutions found that companies actively engaging in digital collaboration experience a 22% improvement in supplier performance over those that don't.

Tip 2: Invest in joint training sessions or workshops, which can strengthen your relationship and ensure that both parties understand each other's processes better. This mutual investment can lead to innovative solutions that benefit both sides, ultimately driving efficiencies within the supply chain.