Navigating Import and Export Certifications for the Best Stepper Motor and Driver: A Comprehensive Guide

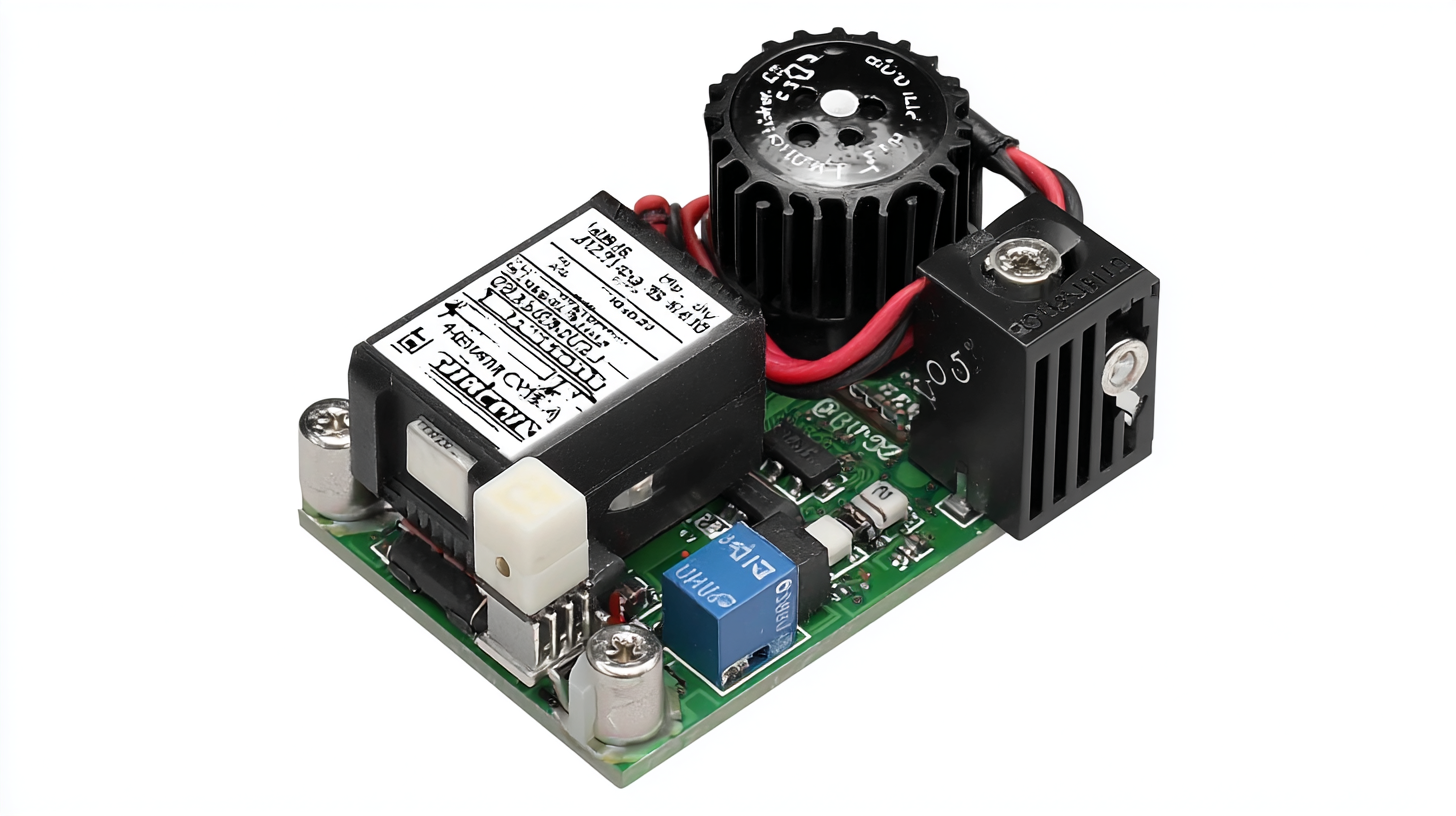

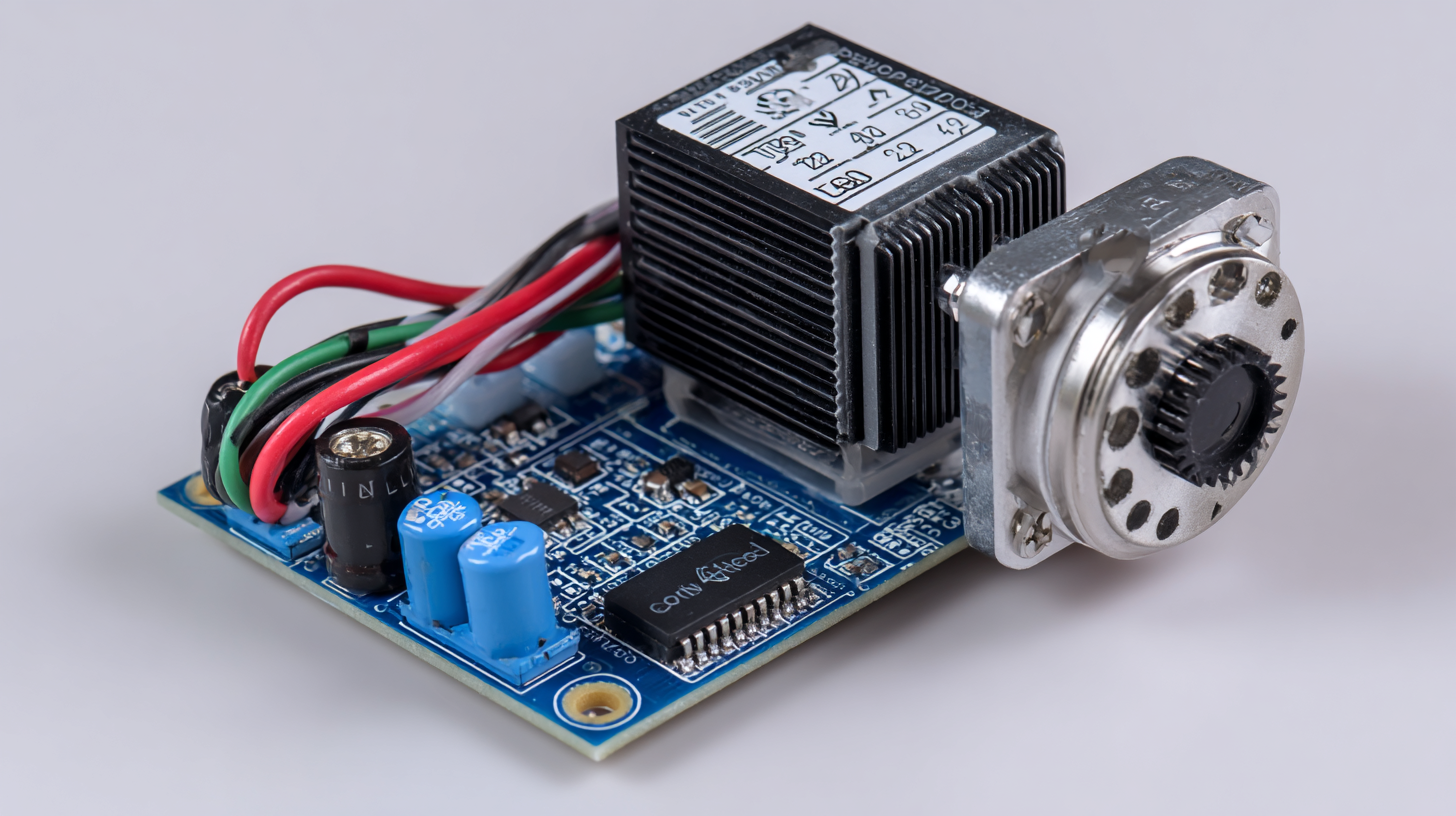

In the rapidly evolving world of automation and robotics, the significance of Stepper Motor and Driver systems cannot be overstated. According to a recent market research report by Research and Markets, the global stepper motor market is projected to reach USD 5.25 billion by 2026, growing at a CAGR of 5.7% from 2021. This surge is driven by increasing demand for precise motion control across various applications, from industrial machinery to consumer electronics. However, navigating the complexities of import and export certifications for these systems can be daunting. Compliance with industry production standards is crucial not only for quality assurance but also for unlocking new markets. In this comprehensive guide, we aim to demystify the certification process and provide manufacturers and distributors with essential insights to ensure their Stepper Motor and Driver products meet both local and international regulatory requirements.

Understanding Import and Export Certifications: Key Terms and Requirements

Navigating the complexities of import and export certifications is essential for businesses dealing with stepper motors and drivers. Understanding key terms, such as CE marking, RoHS compliance, and UL certification, is crucial for smooth international trade. According to a report by MarketsandMarkets, the global stepper motor market is projected to reach $7.5 billion by 2025, highlighting the importance of adhering to certification standards to ensure product acceptance in global markets.

Navigating the complexities of import and export certifications is essential for businesses dealing with stepper motors and drivers. Understanding key terms, such as CE marking, RoHS compliance, and UL certification, is crucial for smooth international trade. According to a report by MarketsandMarkets, the global stepper motor market is projected to reach $7.5 billion by 2025, highlighting the importance of adhering to certification standards to ensure product acceptance in global markets.

Import and export certifications not only verify product safety and efficiency but also enhance market competitiveness. A study by Mordor Intelligence indicates that compliance with certifications can reduce import tariffs by up to 15% in certain regions, significantly impacting the overall cost structure. Therefore, manufacturers must stay informed about the latest regulatory changes and requirements to leverage these benefits effectively and facilitate seamless shipping processes. Proper documentation and adherence to international standards are vital for avoiding delays and penalties during transit.

The Role of International Standards in Stepper Motor and Driver Certification

In the realm of stepper motors and drivers, understanding international certification standards is crucial for ensuring quality and compliance. These certifications act as a benchmark, assuring manufacturers and consumers alike that the products meet specific criteria for safety, performance, and reliability. The interconnectedness of global markets necessitates adherence to these international standards, as they facilitate smoother trade operations and streamline the import-export process. As companies navigate the complexities of certification, it becomes evident that aligning with established norms not only boosts product credibility but also enhances import-export efficiency.

Additionally, as technology evolves, so does the regulatory landscape for automated systems and components such as stepper motors. The need for robust legal frameworks that support innovation while ensuring safety cannot be overstated. Different regions may adopt varying standards, impacting how products are certified and marketed. Thus, companies must stay abreast of both local and international regulations to ensure compliance and harness the full potential of their stepper motor offerings in the global market. This careful navigation of certifications underscores the importance of a strategic approach in maintaining competitive edge through adherence to quality and safety mandates.

Navigating Import and Export Certifications for Stepper Motors and Drivers

This chart illustrates the number of various certifications obtained for stepper motors and drivers. The data shows the importance of international standards in ensuring product quality and compliance for international trade.

Step-by-Step Guide to Securing Necessary Certifications for Importing

When importing stepper motors and drivers, securing the necessary certifications is crucial for compliance and market entry. According to a recent report from Industry Insights, over 55% of companies face delays due to incomplete or incorrect certification documentation. A systematic approach can mitigate these risks significantly. Start by identifying the specific certifications required for your target market, which may include CE, UL, and RoHS. Each certification has its own prerequisites, such as product testing and quality management system audits, which can vary greatly depending on the region.

Once you have a clear understanding of the requirements, create a checklist to guide your certification process. Engaging with third-party testing labs can streamline the validation of your products against compliance standards, as highlighted by the Global Regulatory Compliance Report, which notes that companies that collaborate with certified labs experience a 30% reduction in approval times. Moreover, maintaining rigorous documentation during manufacturing will support your certification efforts and provide peace of mind that your stepper motors and drivers meet international safety and quality expectations.

Navigating Import and Export Certifications for the Best Stepper Motor and Driver: A Comprehensive Guide

| Certification Type | Purpose | Issuing Authority | Validity Period | Notes |

|---|---|---|---|---|

| CE Marking | Compliance with European safety standards | European Commission | Indefinite, subject to regular audits | Mandatory for selling in EU |

| UL Certification | Safety testing for electrical devices | Underwriters Laboratories | Generally 5 years before re-evaluation | Widely recognized in North America |

| RoHS Compliance | Restriction of hazardous substances | European Union | No expiration | Required for electronic components in the EU |

| ISO 9001 | Quality management standards | International Organization for Standardization | 3 years, renewable | Enhances product quality and customer satisfaction |

| FCC Certification | Compliance with electromagnetic interference regulations | Federal Communications Commission | Indefinite | Necessary for electronic devices in the USA |

Challenges in the Certification Process: Common Pitfalls to Avoid

When navigating the certification process for stepper motors and drivers, it's crucial to recognize the common pitfalls that can lead to delays and increased costs. One major challenge is the misunderstanding of regulatory requirements. Manufacturers may overlook specific standards required by different countries, which can result in non-compliance and delayed shipments. It’s essential to thoroughly research and understand the certification requirements applicable to your target markets, as each country may have unique regulations governing electrical components.

Another common issue is inadequate documentation. Many manufacturers underestimate the importance of thorough, accurate documentation for their products. Missing or incomplete paperwork can cause certification applications to be rejected or delayed. It’s vital to maintain meticulous records of all tests, specifications, and compliance measures taken. Engaging with certification bodies early in the process can also help identify critical documentation needs and streamline the approval process, ensuring a smoother path to market for your stepper motors and drivers.

Tips for Ensuring Compliance and Maximizing Import/Export Success

When delving into the intricacies of importing and exporting stepper motors and drivers, ensuring compliance with certification requirements is paramount. Various countries have specific regulations that dictate what certifications are necessary to legally import or export these components. Start by researching the regulations pertinent to your target markets, such as CE marking in Europe or UL certification in the United States. Understanding these requirements not only facilitates smoother transactions but also mitigates the risk of costly fines or delayed shipments.

When delving into the intricacies of importing and exporting stepper motors and drivers, ensuring compliance with certification requirements is paramount. Various countries have specific regulations that dictate what certifications are necessary to legally import or export these components. Start by researching the regulations pertinent to your target markets, such as CE marking in Europe or UL certification in the United States. Understanding these requirements not only facilitates smoother transactions but also mitigates the risk of costly fines or delayed shipments.

Additionally, maintaining open lines of communication with your suppliers and freight forwarders can significantly enhance your import/export success. Collaborating closely with these partners ensures that you are up-to-date on any changes in regulations or compliance standards. Implementing a rigorous documentation process to track certifications and other compliance-related paperwork is equally crucial. This proactive approach will help streamline your operations and build a trustworthy relationship with regulatory bodies, ultimately leading to a more successful and efficient import/export strategy for your stepper motors and drivers.