Understanding Industry Standards for Best Stepper Motor and Controller Selection

In today's rapidly evolving technological landscape, the selection of the right stepper motor and controller is crucial for optimizing performance and efficiency in various applications, from automation to robotics. According to a market research report by Mordor Intelligence, the global stepper motor market is projected to reach USD 4.8 billion by 2026, reflecting a compound annual growth rate (CAGR) of 4.3% from 2021 to 2026. This growth is driven by the increasing demand for precision motion control systems, highlighting the importance of understanding industry standards for selecting the best stepper motor and controller. Properly matching the motor with an appropriate controller not only enhances operational efficiency but also minimizes energy consumption, making it essential for engineers and design professionals to stay informed about the latest advancements in this field.

Importance of Stepper Motors in Precision Applications for 2025 Industry Standards

As industries increasingly rely on automation and precision engineering, the role of stepper motors has become paramount. In 2025, industry standards will place significant emphasis on the accuracy and reliability of stepper motor applications, particularly in sectors such as robotics, medical devices, and CNC machinery. According to a report by MarketsandMarkets, the stepper motor market is projected to reach $5.8 billion by 2025, growing at a CAGR of 6.6%. This growth reflects the heightened demand for precise control in systems that require exact movements and repeatability.

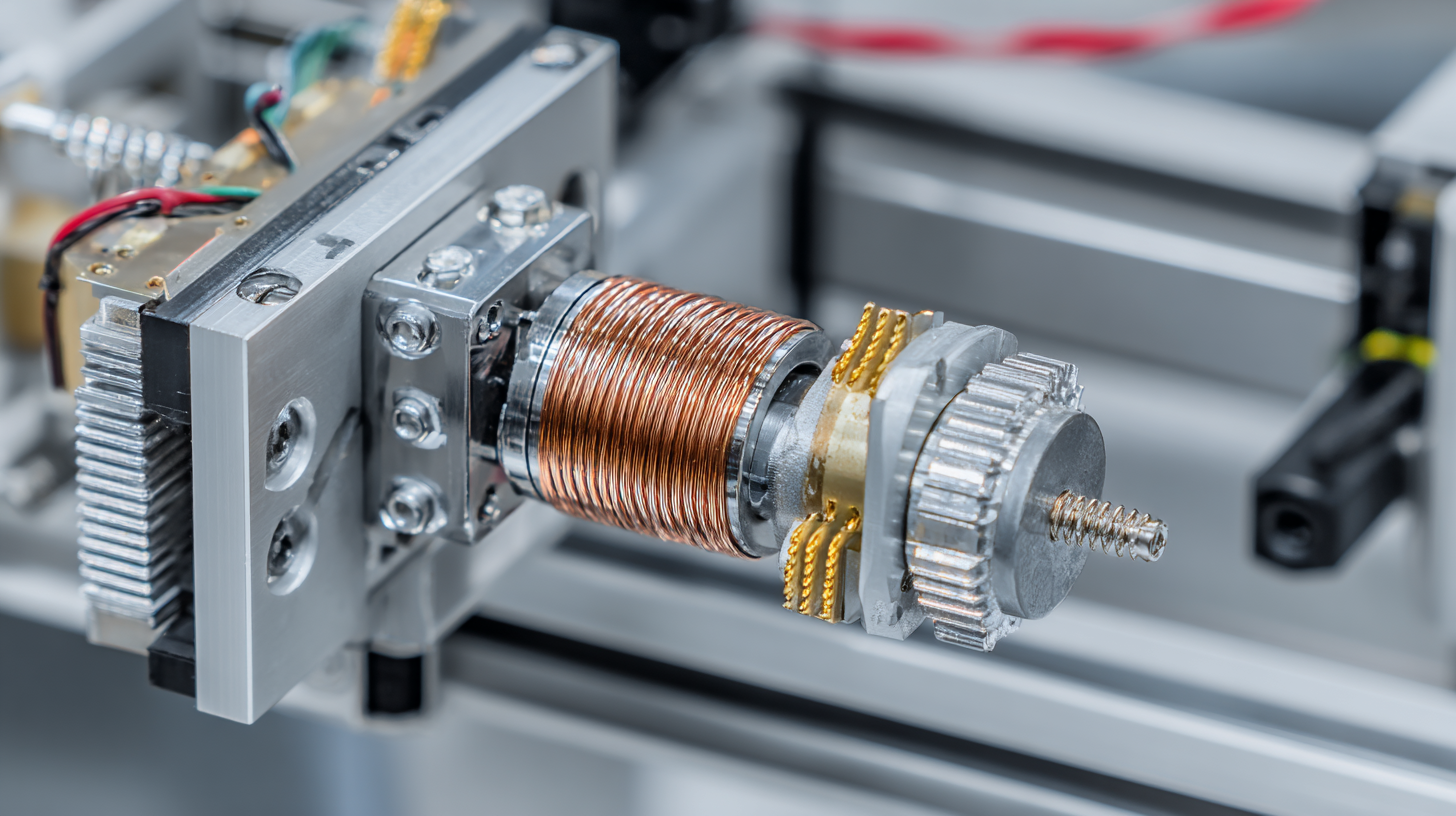

The importance of implementing high-standard stepper motors in precision applications cannot be overstated. With advancements in technology, such as hybrid stepper motors that combine permanent magnet and variable reluctance principles, manufacturers can achieve better performance metrics. For instance, the torque output and efficiency of these motors are critical for applications where precision is vital, as highlighted in the International Electrotechnical Commission's (IEC) guidelines. Furthermore, ensuring compliance with evolving industry standards will not only enhance operational efficiency but also improve safety and reliability, critical factors in the design and selection process of motor systems for various applications.

Stepper Motor Performance Analysis for Precision Applications (2025)

Key Factors for Selecting Stepper Motors and Controllers: Torque, Speed, and Accuracy

When selecting stepper motors and controllers for automation applications, three critical factors come to the forefront: torque, speed, and accuracy. Each of these parameters plays a vital role in ensuring that the motion control systems operate efficiently and meet the desired performance standards. The torque produced by a stepper motor determines its ability to handle loads effectively, while speed considerations affect the overall responsiveness of the system. A motor must provide sufficient torque at desired speeds to prevent lag or stalling, which could compromise the precision of positioning tasks.

In addition to torque and speed, accuracy is paramount. Precision in motion control not only enhances the effectiveness of machinery but also ensures safety and reliability in complex systems. Techniques such as parabolic acceleration and deceleration curves can significantly improve the accuracy of stepper motors by enabling smooth transitions between speeds, thus minimizing mechanical stress. Employing advanced control algorithms, such as fuzzy logic and predictive direct torque control, can further optimize motor performance. These methods allow for adaptive adjustments to changing load conditions, ensuring that the system remains responsive and performs at peak efficiency throughout operations.

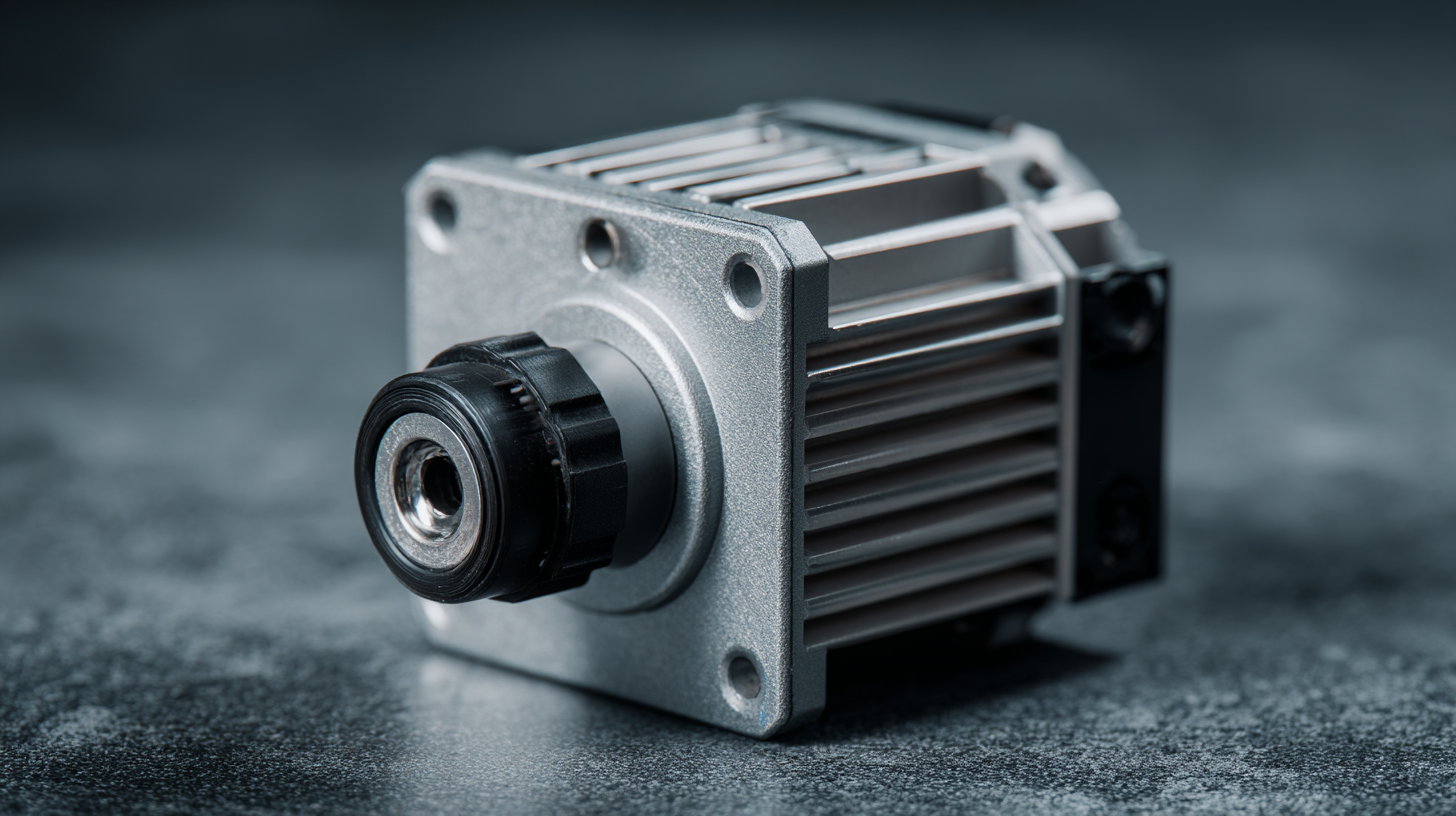

Emerging Trends in Stepper Motor Technology: Integrating IoT and Smart Automation

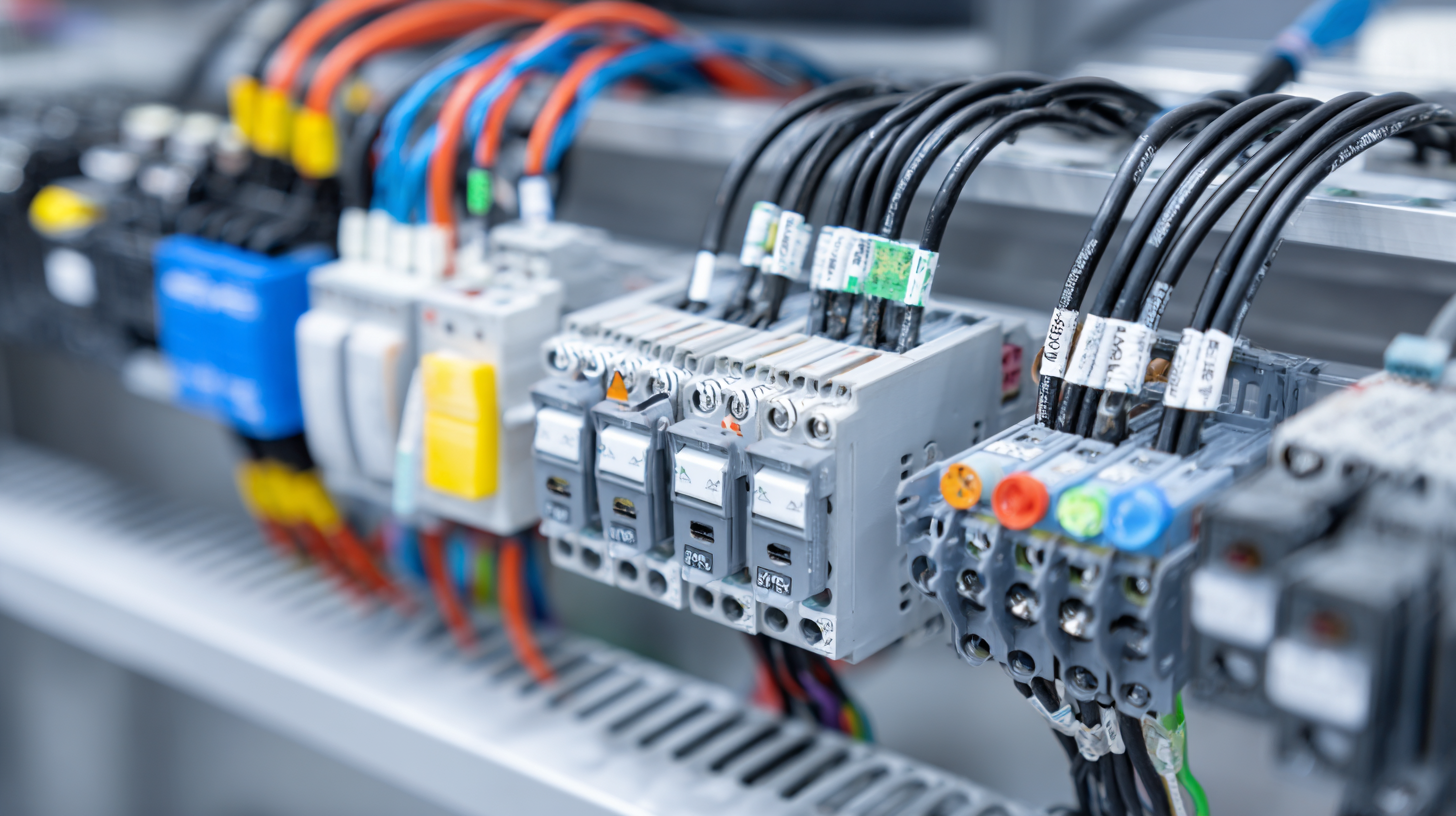

The integration of the Internet of Things (IoT) into stepper motor technology is revolutionizing the way industries approach automation. As more devices become interconnected, stepper motors now play a pivotal role in systems requiring precision and control. Leveraging IoT capabilities, manufacturers can monitor the performance of stepper motors remotely, analyze data in real-time, and optimize operational efficiency. This capability not only enhances machine performance but also allows for predictive maintenance, reducing downtime and improving productivity.

Moreover, the rise of smart automation is leading to a demand for advanced controllers that can manage these sophisticated stepper motor systems. With the ability to communicate with other smart devices, modern controllers facilitate seamless integration and user-friendly management. They enable more complex tasks, such as coordinated movement in robotic arms or precise positioning in CNC machines, making them invaluable in manufacturing and assembly processes. As industries continue to embrace these trends, the synergy between stepper motors, controllers, IoT, and smart automation will undoubtedly drive innovation and efficiency in various applications.

Understanding Industry Standards for Best Stepper Motor and Controller Selection - Emerging Trends in Stepper Motor Technology: Integrating IoT and Smart Automation

| Parameter | Standard Value | Emerging Trend | Integration Aspect |

|---|---|---|---|

| Holding Torque | 0.5 - 2.0 Nm | High Torque Density | IoT-enabled Feedback Loops |

| Step Angle | 1.8° (200 steps/rev) | Microstepping Technology | Smart Motion Control |

| Voltage Rating | 12 - 48 V | Higher Voltage for Efficiency | Remote Operation via IoT |

| Current Rating | 1 - 3 A | Adaptive Current Control | Smart Power Management |

| Controller Type | Digital / Analog | IoT-Enabled Controllers | Cloud Connectivity |

Analyzing Industry Standards: Comparing Performance Metrics of Leading Stepper Motor Brands

When selecting the best stepper motors and controllers for industrial applications, understanding the performance metrics of leading brands is essential. Industry reports from sources like TechNavio indicate that the global stepper motor market is projected to grow at a CAGR of over 7% through 2025, driven by advancements in automation technology and the increasing demand for precise control in diverse applications. Key performance metrics such as torque, step accuracy, and holding torque are critical when comparing different brands. For instance, NEMA 17 stepper motors typically offer holding torque values ranging from 0.2 Nm to 0.5 Nm, significantly impacting their suitability across robotics, CNC machinery, and 3D printing applications.

Furthermore, comprehensive analyses highlight the variations in step accuracy among manufacturers. According to a report by Grand View Research, brands like Moons’ and Oriental Motor consistently outperform their competitors with step resolutions as precise as 1.8 degrees and microstepping capabilities that enhance smooth operation and reduce vibrations. Such performance metrics not only influence the operational efficiency of equipment but also determine the longevity and reliability of the systems in which these motors are integrated. As industries continue to evolve, aligning with reputable stepper motor brands that adhere to stringent quality standards will be imperative for achieving optimal performance.

Future-Proofing Your Projects: Compliance with 2025 Regulations and Sustainability Practices

As industries prepare for a more regulated future, compliance with 2025 regulations becomes paramount, especially in the realm of stepper motors and controllers. Companies are increasingly recognizing the necessity to adapt their operations to meet new environmental standards. The integration of sustainability practices not only addresses regulatory demands but also fosters innovation and aligns with consumer expectations. With predictions indicating that over 70% of mining deals will require stringent environmental compliance documentation, businesses must prioritize environmentally responsible practices now to thrive in the shifting regulatory landscape.

Moreover, the focus on sustainability serves as a powerful driver for corporate growth. By employing eco-friendly technologies and optimizing energy consumption, organizations can enhance their operational efficiency while fulfilling compliance requirements. For instance, the roadmap for future mining operations includes a mandate for recycling over 95% of wastewater, emphasizing the need for robust safety management systems. As industries embrace these changes, adapting stepper motors and controllers to be compliant with upcoming regulations and sustainability goals will greatly benefit long-term project success.