Innovative Techniques in Metal Forming for Enhanced Manufacturing Efficiency

The field of manufacturing is witnessing a significant transformation, driven by the adoption of innovative techniques in metal forming. As reported by the Manufacturing Institute, the global metal forming market is projected to reach $254 billion by 2025, highlighting the critical role of advanced methodologies in enhancing production efficiency. Techniques such as additive manufacturing, advanced die design, and real-time process monitoring are reshaping how industries approach metal forming, allowing for greater precision and reduced waste. Moreover, a study by Deloitte indicates that implementing cutting-edge technologies can boost overall equipment effectiveness by 30%, thereby streamlining operations and fostering sustainable practices. As manufacturers strive to meet rising demands and maintain competitiveness, embracing these innovative metal forming techniques will be essential for achieving superior operational outcomes.

Understanding Advanced Metal Forming Techniques for Modern Manufacturing

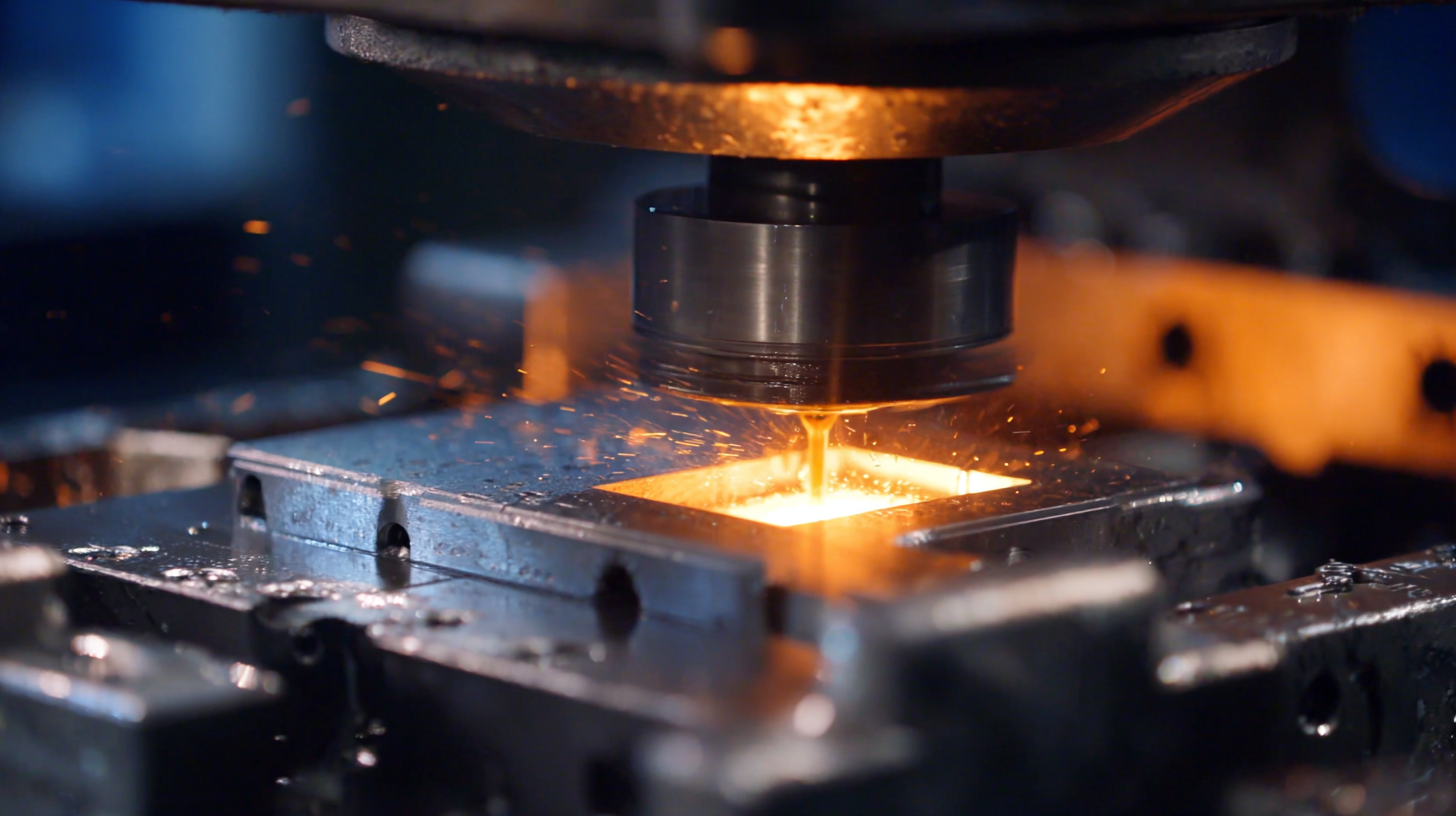

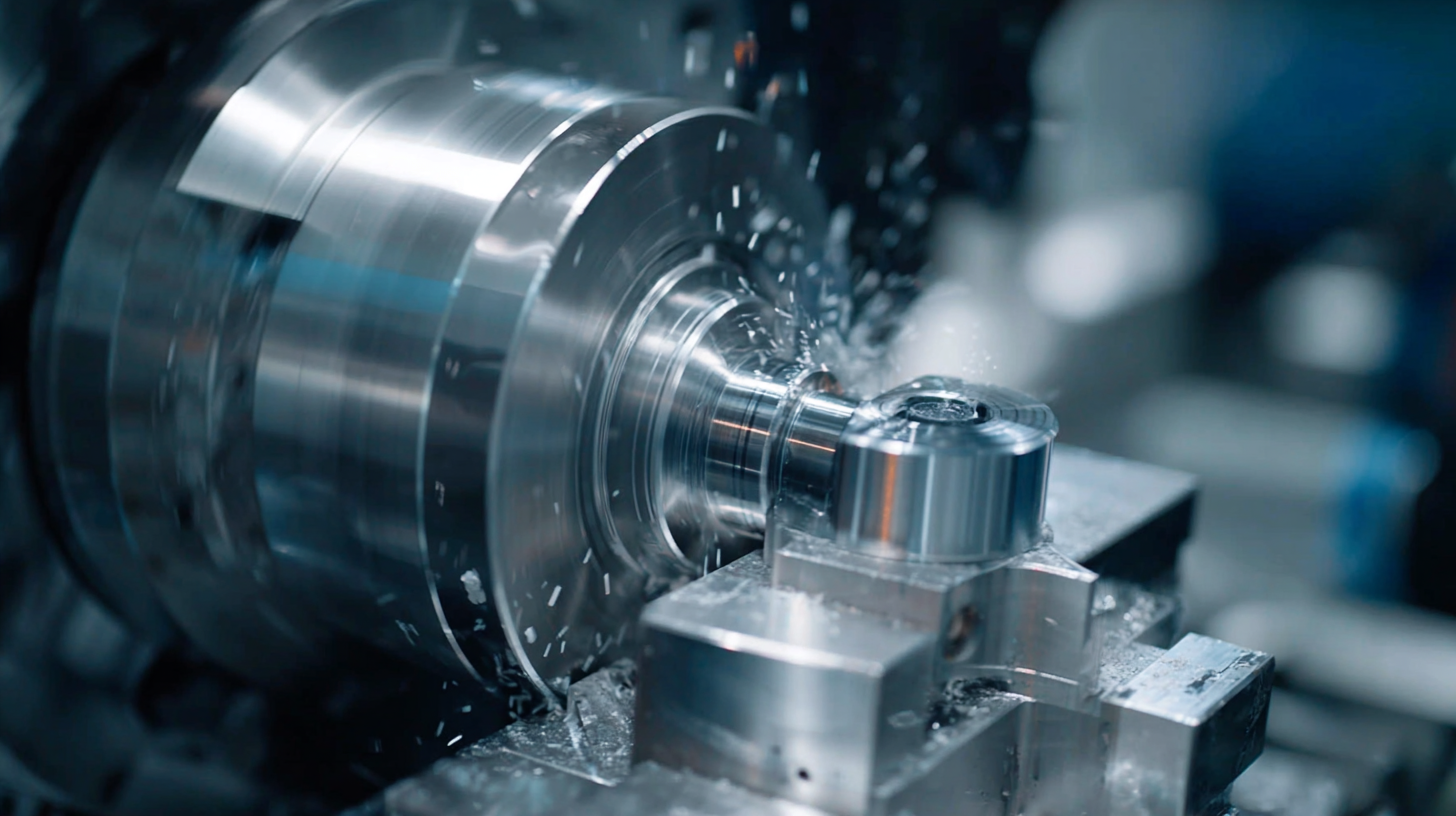

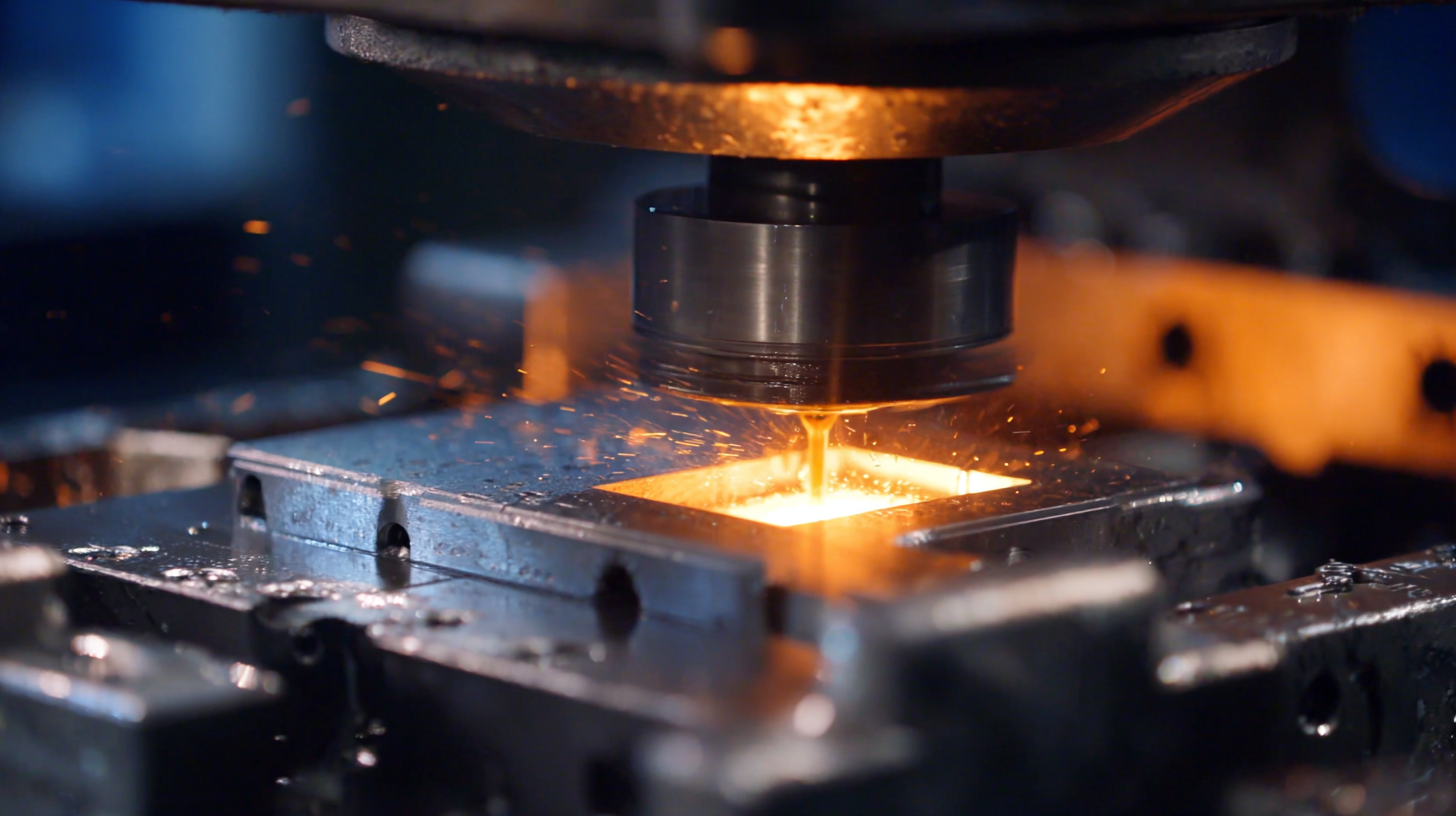

Advanced metal forming techniques play a crucial role in modern manufacturing by enhancing efficiency and precision in the production processes. Techniques such as hot and cold forging, hydroforming, and incremental sheet forming have emerged as essential methods for shaping metals into complex geometries while minimizing waste. These methods enable manufacturers to produce lightweight components that maintain structural integrity, thereby meeting the demands of industries ranging from aerospace to automotive.

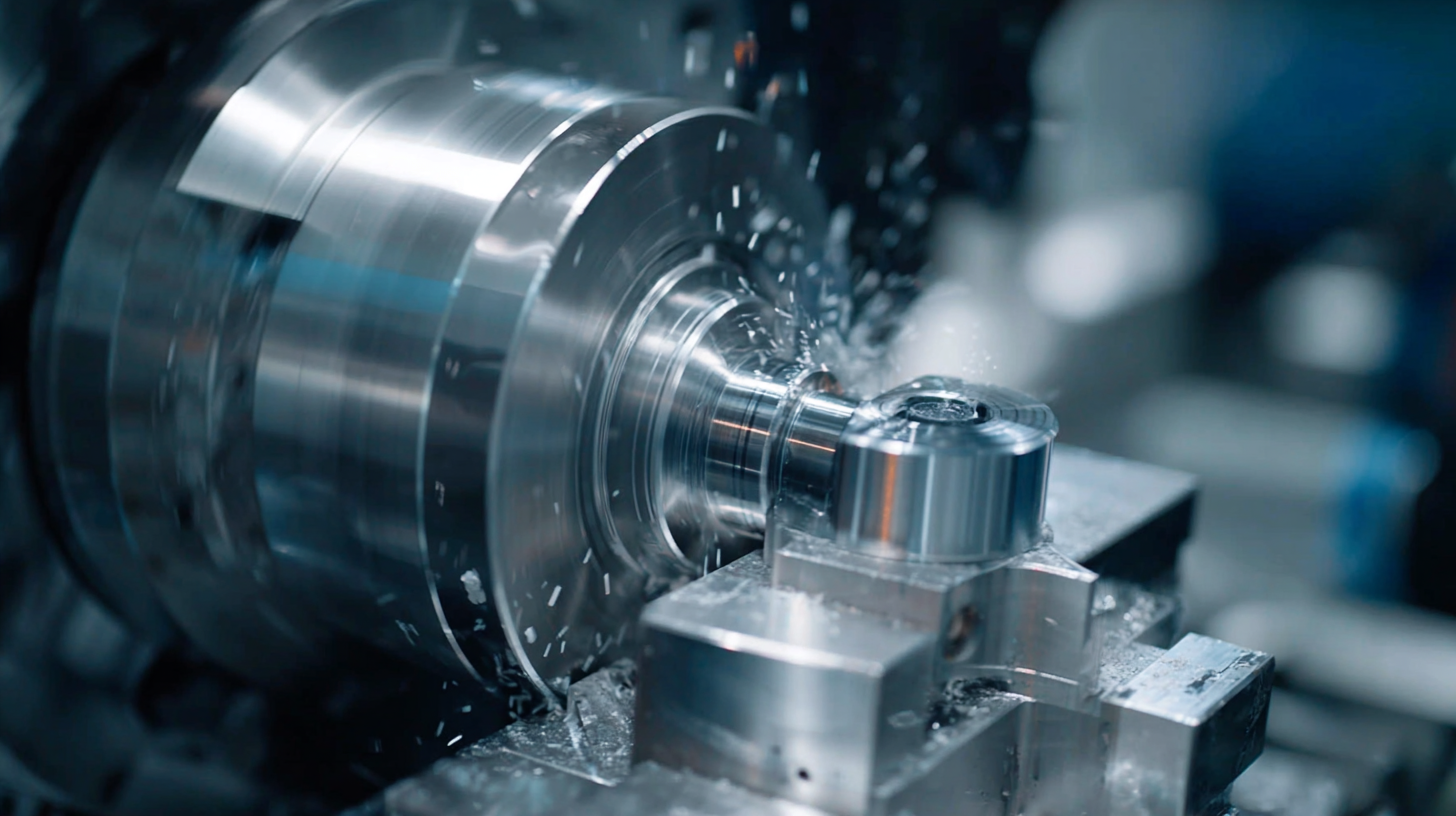

Moreover, the integration of automation and digital technologies into metal forming processes has revolutionized traditional methods. Computer Numerical Control (CNC) machines and robotics have improved accuracy and repeatability in metal shaping, allowing for faster production times and reduced labor costs. Additionally, the use of advanced simulations and modeling tools enables engineers to predict and analyze the outcomes of various forming techniques, optimizing designs before physical production. As these innovative approaches continue to evolve, they will undoubtedly reshape the landscape of manufacturing, driving efficiency and innovation in the industry.

Exploring the Role of Automation in Metal Forming Processes

The metal fabrication industry is witnessing significant advancements through automation, which plays a pivotal role in enhancing manufacturing efficiency. According to industry projections, the global metal fabrication equipment market is expected to grow from $64.64 billion in 2025 to $82.78 billion by 2032, demonstrating a compound annual growth rate (CAGR) of 3.6%. This growth is largely fueled by the adoption of innovative automated processes that streamline fabrication tasks.

In autonomous fabrication, particularly in sheet metal operations, software algorithms are increasingly utilized to optimize workflows. These algorithms identify components best suited for specific cutting and bending techniques, assign ideal routings, and generate necessary programming automatically. By minimizing manual intervention, manufacturers can reduce lead times, enhance product accuracy, and ultimately lower production costs. As automation continues to evolve, its integration into metal forming processes will not only redefine operational efficiencies but also enable more sophisticated and customized fabrication solutions.

Innovative Techniques in Metal Forming for Enhanced Manufacturing Efficiency

This chart illustrates the importance of automation in various metal forming processes, measuring efficiency improvements in percentage over traditional methods.

Leveraging Computational Modeling for Precision Metal Forming

The integration of computational modeling into metal forming processes is revolutionizing the manufacturing landscape by enhancing precision and efficiency. Techniques such as SLF-YOLO, a lightweight object detection model, have addressed the critical need for accurate metal surface defect detection. By leveraging advanced machine learning algorithms, manufacturers can significantly reduce detection times and improve quality control, ensuring that only products meeting stringent standards proceed through the production line.

Additionally, innovations in multiscale modeling enable engineers to simulate the behavior of materials at different scales, thereby providing insights into anisotropic characteristics that affect forming processes. For instance, the anisotropic behavior of materials like 316 L stainless steel can remarkably alter forming outcomes, highlighting the importance of rigorous computational analysis. Such simulations not only streamline tooling design but also validate processes before physical implementation, fostering a more efficient and cost-effective metal forming environment.

These advancements underscore the pivotal role computational modeling plays in modern manufacturing, driving the industry toward unparalleled efficiency and precision.

Integrating Sustainable Practices in Metal Forming Operations

In the ever-evolving landscape of metal forming operations, integrating sustainable practices is becoming increasingly vital. As industries shift towards more responsible practices, companies are realizing that sustainability not only benefits the environment but also enhances operational efficiency. By adopting innovative techniques in metal forming, such as using eco-friendly materials and optimizing energy consumption, manufacturers can significantly reduce their carbon footprint while improving productivity.

**Tips for Sustainable Metal Forming:**

1. Explore alternatives to traditional raw materials, such as recycled metals, to minimize waste.

2. Invest in energy-efficient machinery that reduces power consumption without compromising quality.

3. Implement a robust supply chain management strategy that emphasizes sustainable sourcing and stakeholder engagement.

In addition to the operational benefits, a commitment to sustainability can enhance supplier relationships and customer loyalty. By transparently sharing sustainability goals and achievements, companies can foster trust and collaboration with partners. As the mining and metals industry moves toward sustainable innovation, the future looks promising for those who prioritize both performance and ecological responsibility.

Innovative Techniques in Metal Forming for Enhanced Manufacturing Efficiency - Integrating Sustainable Practices in Metal Forming Operations

| Technique |

Description |

Efficiency Improvement (%) |

Sustainability Impact |

Implementation Cost ($) |

| Hydroforming |

Uses high-pressure fluid to shape metal. |

25% |

Reduces material waste |

20,000 |

| Incremental Forming |

Progressively shapes sheet metal using a CNC tool. |

30% |

Uses less energy |

15,000 |

| Additive Manufacturing Integration |

Combines 3D printing with traditional forming techniques. |

40% |

Minimizes scrap production |

25,000 |

| Thermomechanical Processing |

Controls temperature during deformation. |

20% |

Enhances material properties |

18,000 |

| Smart Sensors and IoT |

Real-time monitoring of forming processes. |

35% |

Improves process efficiency |

30,000 |

Evaluating the Impact of Innovative Materials on Metal Forming Efficiency

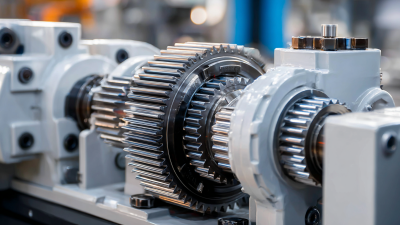

Innovative materials play a pivotal role in enhancing metal forming efficiency, significantly impacting the manufacturing landscape. Recent advancements in composites and high-strength alloys have led to improvements in the mechanical properties of metals, enabling manufacturers to create more complex shapes while reducing material waste. These materials are designed to withstand higher temperatures and pressures, resulting in shorter processing times and lower energy consumption, which ultimately contributes to a more sustainable manufacturing process.

Furthermore, the integration of smart materials, such as shape memory alloys, allows for dynamic adaptability during the forming process. These materials can respond to external stimuli, offering manufacturers flexible options to adjust their techniques according to specific requirements. By leveraging these innovative materials, manufacturers can improve productivity, optimize tool life, and enhance product quality, leading to a competitive edge in the market. The interplay between advanced materials and metal forming techniques is becoming increasingly crucial as industries strive for higher efficiency and sustainability.