Why Manufacturing Solutions are Essential for Business Growth and Efficiency

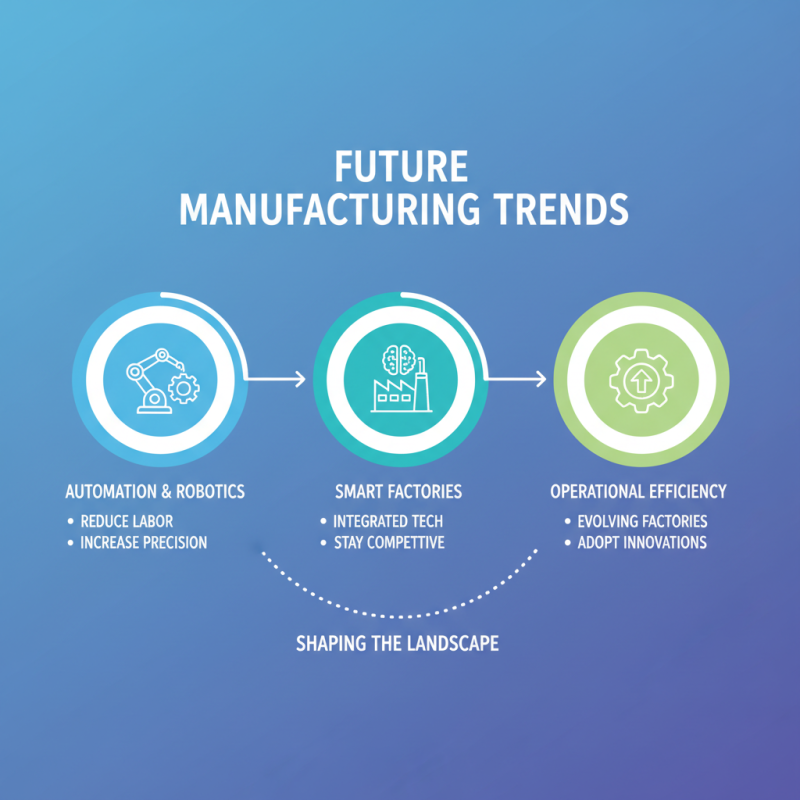

In today’s fast-paced market, businesses must adapt quickly to stay competitive. Manufacturing solutions have emerged as vital tools for driving growth and maximizing efficiency. These solutions streamline operations, reduce waste, and enhance productivity.

Manufacturing solutions often include advanced technologies like automation and data analytics. They provide insights that help organizations make informed decisions. However, the implementation of these solutions is not without challenges. Companies may struggle with integration and require time to retrain employees.

Choosing the right manufacturing solutions can feel overwhelming. There are numerous options available, and each business presents unique needs. It is crucial to reflect on specific requirements and potential obstacles. Embracing these solutions can lead to significant benefits but may require a shift in mindset and operations.

The Role of Manufacturing Solutions in Modern Business Strategies

In today's competitive landscape, manufacturing solutions play a critical role in shaping modern business strategies. Companies of all sizes are increasingly recognizing the need for streamlined operations. Efficient manufacturing processes lead to quicker turnaround times and reduced waste. However, not all businesses utilize these solutions effectively. Many struggle with integration and implementation. As a result, they may miss opportunities for growth.

Investing in technology and automation is essential. It can enhance productivity and drive innovation. Yet, this shift can be overwhelming. Employees might resist new systems. Training and support are often lacking, leading to confusion. Companies need to address these obstacles to fully benefit from manufacturing solutions. A culture of adaptability and learning is vital for success.

Moreover, sustainability is becoming a crucial factor in manufacturing. Consumers now demand eco-friendly practices. Businesses must find ways to reduce their carbon footprint while maintaining efficiency. Balancing profitability with responsibility can be challenging. Yet, those who succeed will stand out in the market. Failing to adapt could result in losing valuable customers and market share.

Key Benefits of Implementing Manufacturing Solutions for Growth

Manufacturing solutions play a pivotal role in driving business growth and enhancing operational efficiency. According to a 2022 report by the International Data Corporation, companies that implement advanced manufacturing technologies can increase their productivity by up to 30%. This increase comes from streamlined processes and reduced waste, which are crucial for staying competitive in today's fast-paced market.

Moreover, having the right manufacturing solutions allows businesses to respond quickly to market changes. A study from Deloitte highlighted that adaptive manufacturing practices could help firms achieve a 15% reduction in lead times. This agility is essential, yet many companies still struggle with outdated processes that hinder their progress. This disconnect often leads to stagnation, especially when competitors embrace innovation. Companies must reflect on their current strategies to avoid falling behind.

Additionally, implementing these solutions can enhance quality control. Research from the Manufacturing Performance Institute indicates that firms utilizing automation and data analytics can reduce defects by 50%. However, not all organizations are leveraging this potential. Many fear the upfront investment or face resistance to change. Businesses should consider that the long-term benefits often outweigh initial costs. Overcoming these hurdles is vital for sustained success and growth in a competitive landscape.

Impact of Manufacturing Solutions on Business Growth and Efficiency

Efficiency Improvements Through Advanced Manufacturing Technologies

Advanced manufacturing technologies play a crucial role in enhancing efficiency. Data from the World Economic Forum indicates that companies adopting these technologies can improve productivity by up to 30%. Techniques like automation and data analytics streamline operations. These tools help identify bottlenecks and reduce waste. Manufacturers must embrace these tools to stay competitive.

Incorporating technologies like additive manufacturing further boosts efficiency. According to a report by Deloitte, 74% of companies using additive manufacturing saw reduced production times. This shift leads to faster time-to-market for products. However, not all businesses have adapted effectively. Many still rely on outdated processes, which can hinder growth.

Moreover, workforce training remains a challenge. Although technology advances, employees must keep pace. A survey by PwC found that 79% of manufacturers struggle with skill shortages. This gap can slow down the implementation of advanced solutions. Investing in a skilled workforce is essential. Companies must prioritize training to maximize potential.

Case Studies: Successful Business Growth via Manufacturing Solutions

In today’s competitive landscape, manufacturing solutions play a critical role in driving business growth. Take a look at how companies are leveraging these solutions successfully. A study from the Manufacturing Institute revealed that 90% of manufacturers see technology integration as essential for enhancing productivity. This is not just about speed; it’s about efficiency and quality.

For example, a mid-sized manufacturer adopted a new automation system. Initially, there were challenges, including staff resistance and integration issues. However, after refining the approach, productivity increased by 25%. Reporting reflects a common scenario; companies often underestimate the resistance to change within their teams.

Another case from a leading industry report indicates that businesses implementing smart technologies boost their revenue by 15% on average. Yet, the journey is not perfect. Many companies still face hurdles like data management and training. Addressing these struggles is vital for long-term success. Companies need to embrace a culture of continuous improvement. The path to efficiency can be bumpy, but the rewards are significant.

Why Manufacturing Solutions are Essential for Business Growth and Efficiency

| Case Study |

Solution Implemented |

Key Metrics Before |

Key Metrics After |

Growth Achieved |

| Case Study 1 |

Automated Production Line |

Production Rate: 100 units/hr |

Production Rate: 150 units/hr |

50% Increase |

| Case Study 2 |

Supply Chain Optimization |

Lead Time: 30 days |

Lead Time: 20 days |

33% Reduction |

| Case Study 3 |

Quality Control System |

Defect Rate: 5% |

Defect Rate: 1% |

80% Improvement |

| Case Study 4 |

Lean Manufacturing Implementation |

Waste: 20% of Production |

Waste: 5% of Production |

75% Reduction |