Top Strategies for Maximizing Efficiency with the Best Stepper Motor and Controller Solutions

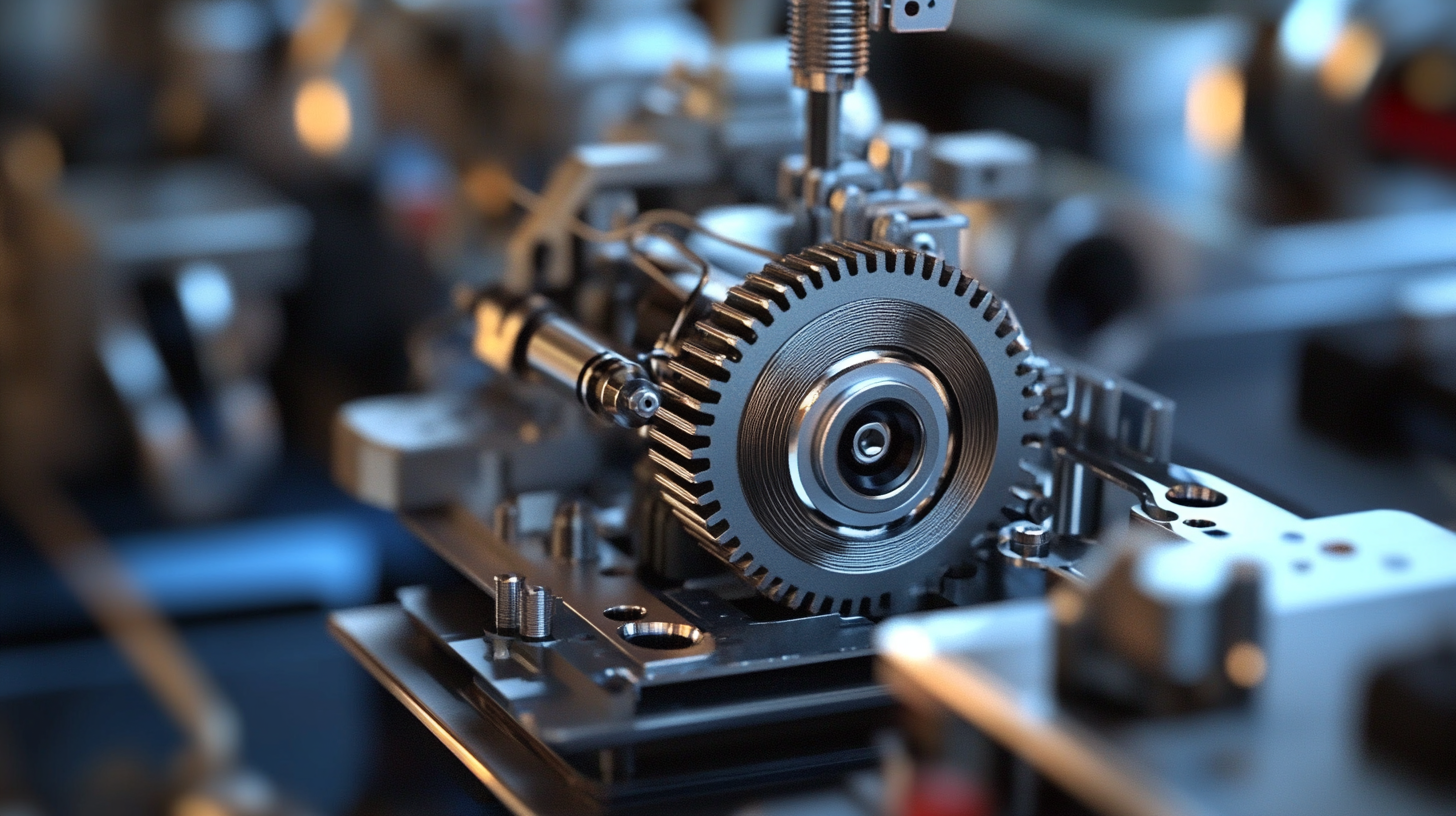

In today’s rapidly evolving industrial landscape, the demand for precision and efficiency has never been greater. According to a recent report by the Research Institute for Advanced Manufacturing, stepper motors and controllers are projected to see a growth rate of over 6% annually through 2028, driven by their unparalleled ability to deliver accurate positioning, high torque at low speeds, and superior control in applications ranging from robotics to CNC machinery. As industries strive to enhance their operational efficiency, understanding how to effectively implement the best stepper motor and controller solutions becomes imperative. This blog will explore top strategies to maximize efficiency with these technologies, ensuring that businesses can thrive in an increasingly competitive market.

Key Features to Look for in Stepper Motors for Optimal Performance

When selecting stepper motors for optimal performance, it is crucial to focus on key features that significantly enhance efficiency. One vital aspect is torque output. According to a report by the International Society of Automation, motors with at least 0.5 Nm of holding torque are essential for applications demanding precise movements and heavy loads. A higher torque rating allows for better performance under varied load conditions, ultimately leading to improved machine throughput.

Another critical feature to consider is step angle, which dictates the resolution of the motor's movement. Stepper motors with smaller step angles, such as 1.8° or even 0.9°, provide finer control and smoother operation, reducing the risk of vibration and resonance during performance. A study from the Journal of Robotics and Automation indicates that motors with smaller step angles can increase positioning accuracy by up to 50%, making them ideal for high-precision applications.

Another critical feature to consider is step angle, which dictates the resolution of the motor's movement. Stepper motors with smaller step angles, such as 1.8° or even 0.9°, provide finer control and smoother operation, reducing the risk of vibration and resonance during performance. A study from the Journal of Robotics and Automation indicates that motors with smaller step angles can increase positioning accuracy by up to 50%, making them ideal for high-precision applications.

Finally, the type of controller paired with the stepper motor can greatly influence performance. Advanced controllers with microstepping capabilities are known to enhance smoothness and efficiency. Data shows that microstepping can improve torque output by 30% while reducing power consumption and heat generation. Investing in a quality motor and an efficient controller can significantly maximize operational efficiency and performance in various automated systems.

Understanding the Role of Controllers in Enhancing Stepper Motor Efficiency

Stepper motors are increasingly recognized for their precision and reliability in various applications, making them a popular choice in automation and robotics. However, to optimize their performance, the role of controllers cannot be overstated. Advanced controllers are essential in enhancing stepper motor efficiency by providing precise pulse control, which directly impacts the motor's torque, speed, and positioning accuracy.

Research indicates that the integration of sophisticated closed-loop control systems can improve the efficiency of stepper motors by up to 40%, compared to traditional open-loop systems. These systems allow for real-time adjustments based on feedback from the motor's performance, effectively reducing issues such as missed steps and overheating. In particular, utilizing current control techniques can lead to a significant decrease in energy consumption, with some studies showing reductions of up to 30% in power usage, while maintaining performance and extending the lifespan of the motor.

Furthermore, employing intelligent motion control algorithms enables stepper motors to operate more smoothly and responsively. By analyzing operational conditions and adjusting parameters dynamically, these controllers can minimize mechanical stress and wear, ensuring longevity and reliability. Data from industry reports underscore the importance of selecting the right controller, with high-performance models demonstrating notable advancements in reducing operational costs and improving overall system throughput.

Integration Techniques for Stepper Motors in Modern Industrial Applications

In today’s fast-paced industrial landscape, the integration of stepper motors into automation systems is rapidly gaining traction. According to the latest report from MarketsandMarkets, the global stepper motor market is projected to reach $4.99 billion by 2026, growing at a CAGR of 7.1%. This surge is primarily driven by the need for precise positioning and control in applications such as robotics, CNC machinery, and 3D printing. Effective integration techniques are essential to harness the full potential of these motors, ensuring they operate at peak efficiency within complex systems.

One of the leading strategies for successful integration involves the use of advanced controllers that facilitate seamless communication between the motor and the machine's control system. Industry data highlights that employing closed-loop control systems can enhance performance by reducing energy consumption by up to 20% compared to open-loop systems. Furthermore, optimizing the mechanical design to accommodate stepper motors plays a crucial role in maintaining operational stability, reducing vibrations, and prolonging equipment lifespan. By implementing these integration techniques, manufacturers can significantly increase throughput and reduce maintenance costs, positioning themselves competitively in the market.

Top Strategies for Maximizing Efficiency with the Best Stepper Motor and Controller Solutions

| Application Area | Stepper Motor Type | Controller Type | Efficiency Rating | Key Integration Technique |

|---|---|---|---|---|

| 3D Printing | Hybrid Stepper Motor | Microstepping Controller | 90% | Closed-loop Feedback |

| CNC Machining | Permanent Magnet Stepper | PID Controller | 85% | Interpolation Techniques |

| Assembly Automation | Bipolar Stepper Motor | Sensorless Controller | 88% | Torque Control Methods |

| Robotics | Unipolar Stepper Motor | Open-loop Controller | 80% | Dynamic Modulation |

| Medical Equipment | High-torque Stepper Motor | Smart Controller | 92% | Precision Positioning |

Future Trends in Stepper Motor Technology and Their Impact on Efficiency

As industries strive for greater automation and precision, the future trends in stepper motor technology are poised to significantly enhance efficiency. According to a recent report by MarketsandMarkets, the global stepper motor market is projected to grow from USD 2.8 billion in 2021 to USD 4.2 billion by 2026, reflecting a compound annual growth rate (CAGR) of 8.4%. This growth is driven by the demand for energy-efficient solutions in sectors ranging from robotics to manufacturing.

One of the key advancements is the integration of smart technologies into stepper motors and controllers. With the rise of Industry 4.0, smart stepper motors equipped with IoT capabilities are enabling real-time monitoring and control, enhancing operational efficiency. A study by the International Journal of Advanced Manufacturing Technology highlights that these innovations can lead to up to 25% reductions in energy consumption, while improving the precision of motion applications. As these technologies evolve, they not only promise to optimize performance but also contribute to sustainable manufacturing practices, aligning with global energy reduction goals.

Best Practices for Maintenance and Troubleshooting of Stepper Motor Systems

Maintaining a stepper motor system requires a proactive approach to ensure longevity and peak performance. According to a recent industry report, proper maintenance can extend the lifespan of a stepper motor by up to 40%, ultimately reducing replacement costs and downtime. Regular inspections and cleanings are crucial, as dust and debris can drastically impair motor function. Moreover, monitoring operating temperatures and ensuring that motors never exceed their rated thresholds can prevent overheating and failure, which are common issues in high-demand environments.

**Tip:** Schedule routine maintenance checks every three to six months, depending on the application. This should include lubrication of moving parts and checks for wear and tear.

In the realm of troubleshooting, identifying issues early can save time and resources. Reports indicate that approximately 30% of stepper motor failures are attributed to electrical issues, such as incorrect wiring or insufficient power supply. A systematic approach to diagnosing these problems is essential. Utilizing oscilloscopes to monitor signal quality can reveal underlying issues before they escalate.

**Tip:** Keep a detailed log of performance metrics and anomalies. This data can provide insight into recurring problems and simplify troubleshooting efforts when issues arise.