Understanding the Mechanics of Planetary Gears and Their Applications in Modern Engineering

In modern engineering, the significance of planetary gears cannot be overstated, as they play a crucial role in the design of efficient mechanical systems across various industries. According to a report by Grand View Research, the global market for gear technologies, including planetary gears, is projected to reach USD 265.12 billion by 2027, exhibiting a compounded annual growth rate (CAGR) of 6.7% from 2020. This surge in demand is driven by the increasing need for compact and efficient power transmission solutions in applications ranging from automotive to aerospace.

Planetary gear systems, characterized by their unique arrangement of gears revolving around a central sun gear, offer advantages such as high torque density, reduced size, and the ability to handle multiple inputs and outputs. As engineering challenges become more complex, understanding the mechanics of planetary gears is imperative for innovating and optimizing modern machinery and technology.

The Basic Principles of Planetary Gear Systems Explained

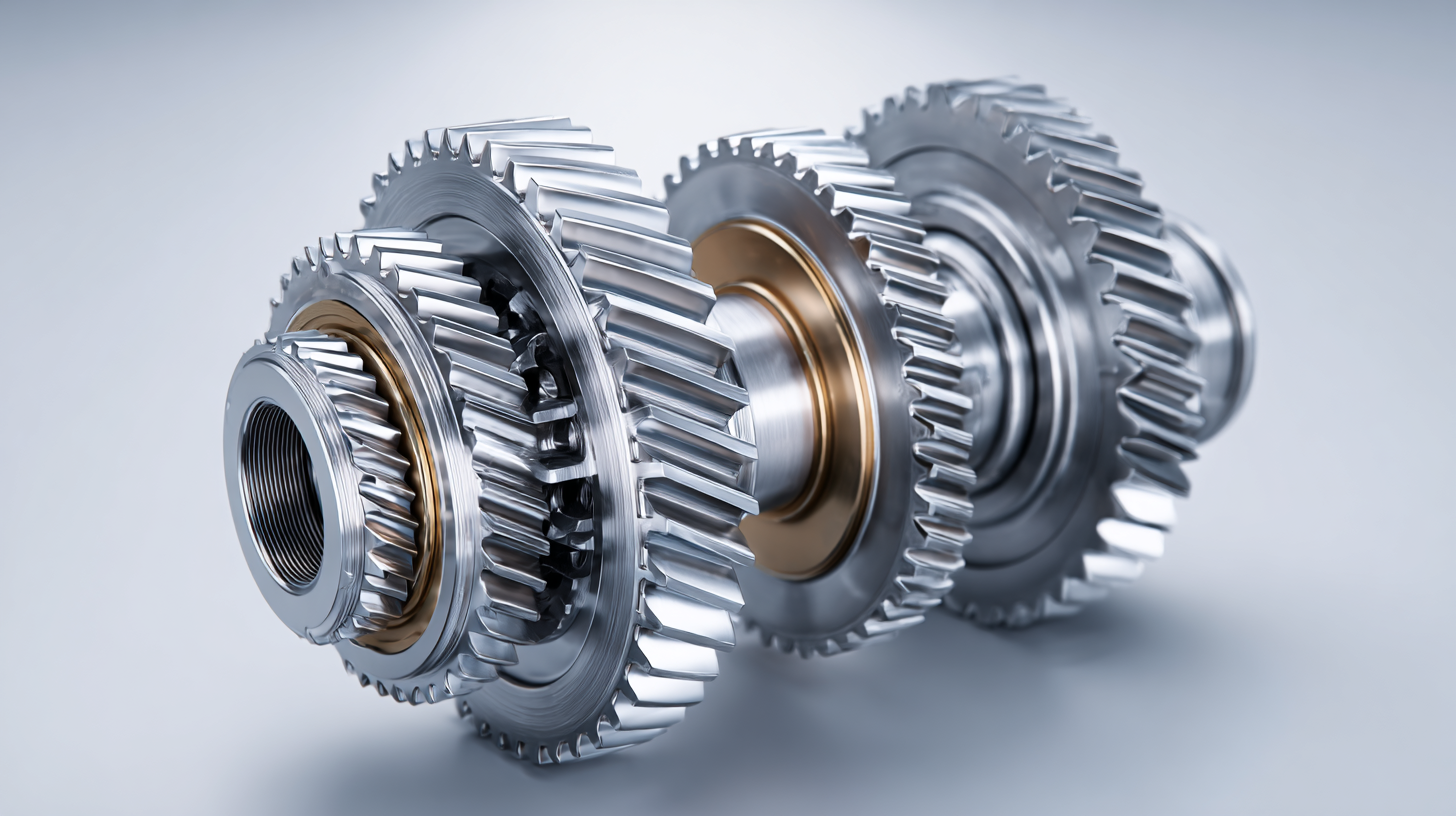

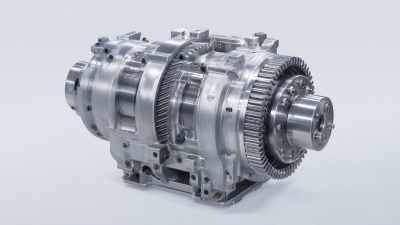

Planetary gear systems, also known as epicyclic gear systems, are crucial components in modern engineering, known for their compact design and high torque transmission capabilities. At the heart of their operation is the arrangement consisting of a central sun gear, planetary gears that revolve around it, and a ring gear that encircles them. This unique setup allows for multiple gear ratios to be achieved without the need for complex adjustments, making them particularly beneficial in applications such as gearboxes for automotive and aerospace industries. According to a report by MarketsandMarkets, the global market for planetary gear systems is projected to reach $8 billion by 2025, reflecting their growing importance in various engineering fields.

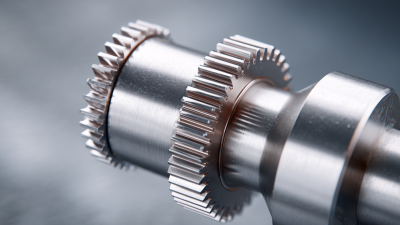

The basic mechanics behind planetary gears involve the distribution of load among multiple gears, resulting in reduced wear and increased lifespan compared to traditional gear systems. In an analysis published in the Journal of Mechanical Engineering, it was highlighted that the efficiency of planetary gears can exceed 95%, which is significantly higher than that of conventional gear configurations. This efficiency, coupled with their ability to handle high power density, makes them ideal for applications where space and weight are critical, such as in electric vehicles where optimizing energy consumption is paramount.

Understanding Planetary Gear Efficiency

This bar chart illustrates the efficiency percentages of different planetary gear ratios. As observed, the efficiency tends to improve with higher gear ratios, demonstrating how advanced gear systems enhance operational performance in engineering applications.

Key Components and Functionality of Planetary Gears

Planetary gears play a crucial role in modern engineering due to their unique design and functionality.

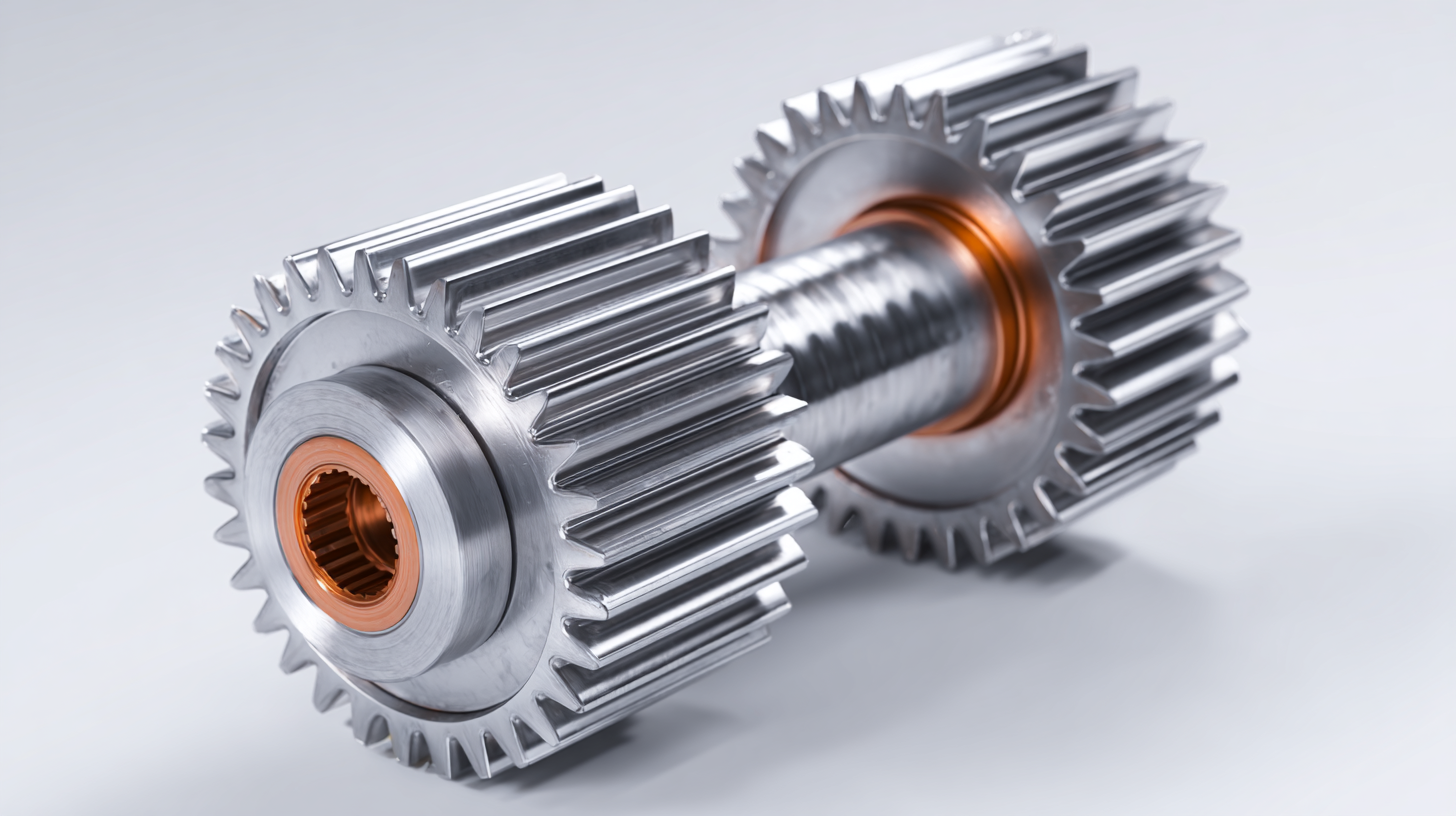

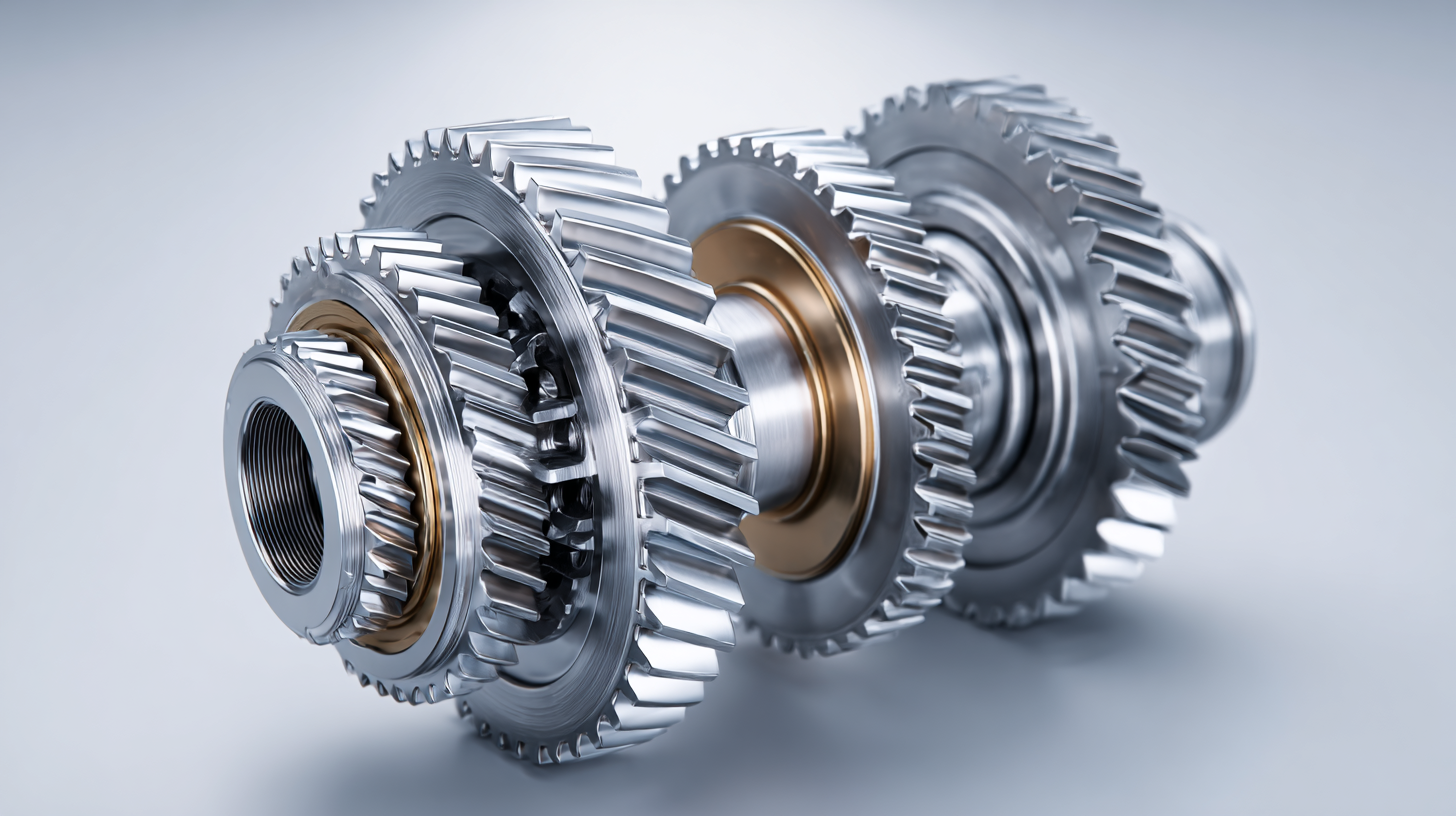

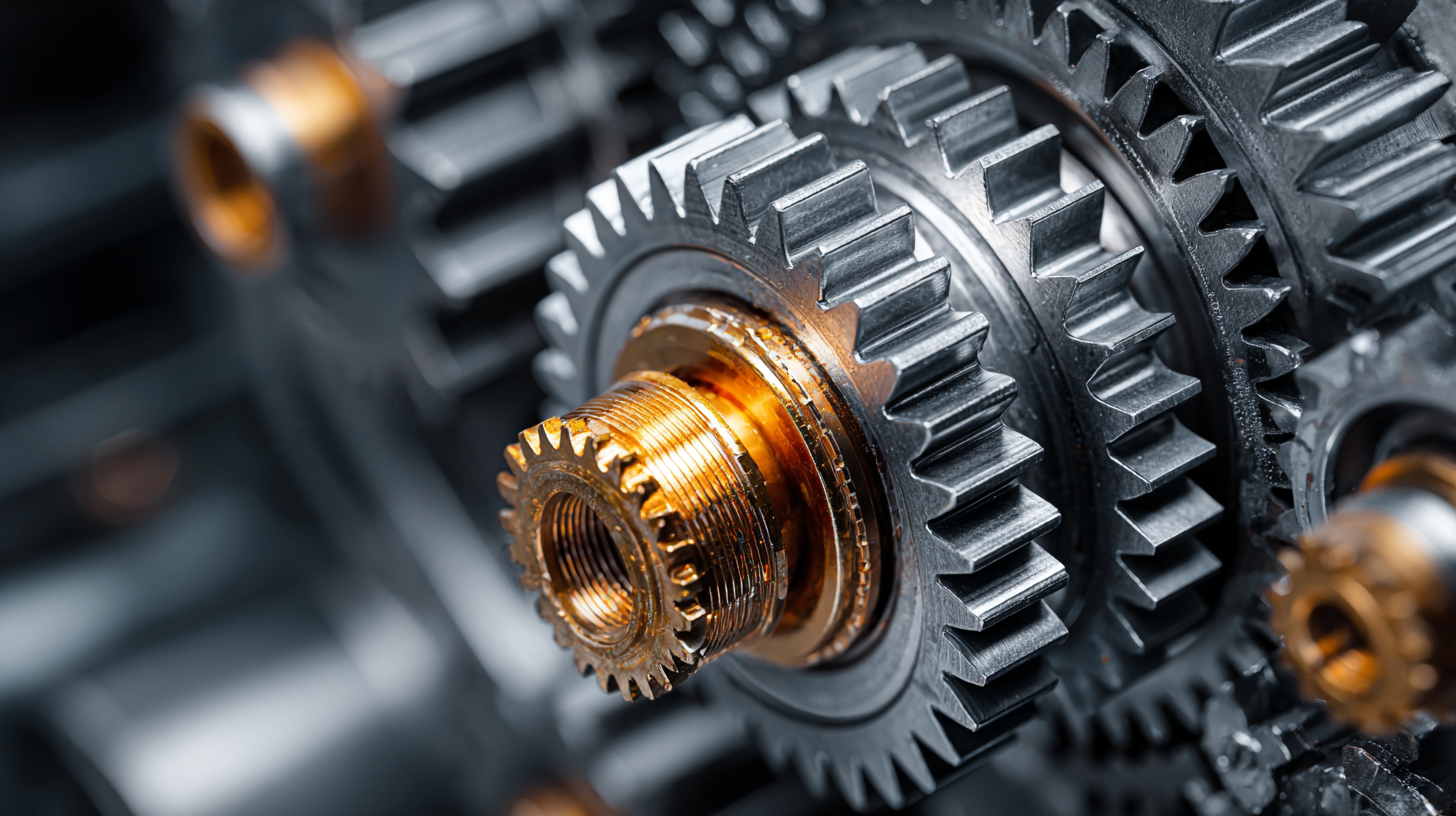

Comprising three main components—sun gear, planet gears, and ring gear—these systems distribute load effectively, resulting in enhanced efficiency and compactness.

The sun gear is at the center, driving the planet gears which revolve around it and engage with the ring gear. This arrangement allows for high torque output in a smaller footprint, making planetary gears essential in applications ranging from automotive transmissions to robotics.

According to a 2022 market research report by Research and Markets, the planetary gearbox market is projected to reach $3.5 billion by 2028, highlighting the growing demand for more efficient gear systems.

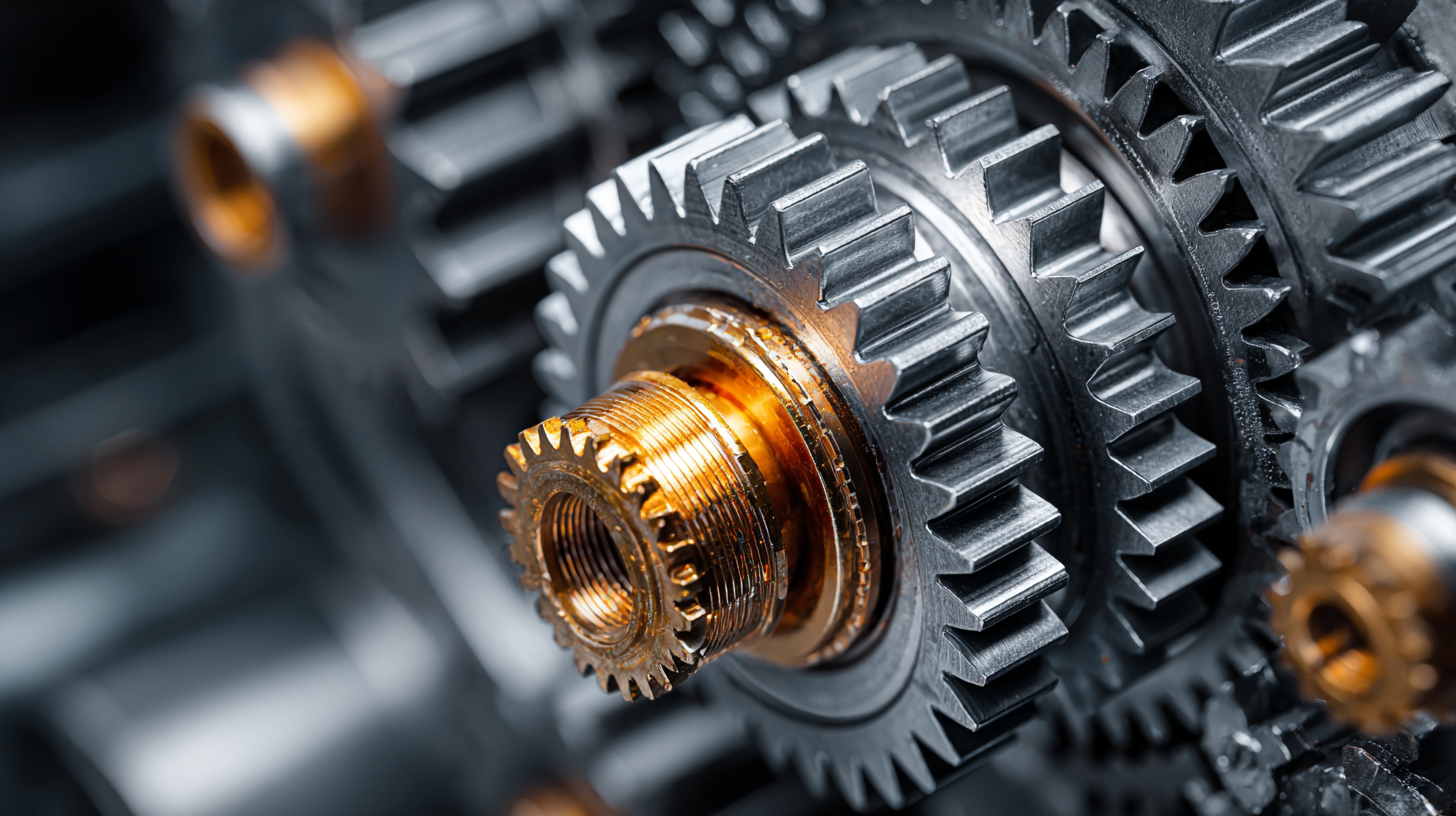

When incorporating planetary gear systems in engineering designs, keep in mind that optimal gear selection can significantly impact performance. Ensure that the gear materials are chosen based on the application's load capacity and environmental conditions.

Using materials like high-strength steel can enhance durability and minimize wear in demanding applications. Additionally, proper lubrication is vital to reduce friction and prevent overheating, which is particularly important in high-speed operations.

Understand that not all planetary gear designs are equal; customization might be necessary to meet specific operational needs.

Testing different configurations, such as the number of planet gears, can help determine the most efficient setup for your project. As suggested by the Mechanical Engineering Journal, engineers should always consider the gear train's overall efficiency and potential noise generation in their designs.

Applications of Planetary Gears in Automotive Engineering

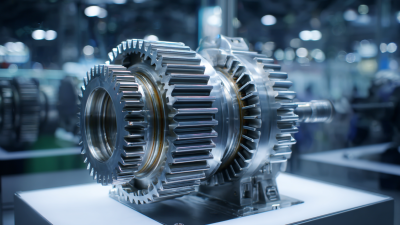

Planetary gears play a crucial role in automotive engineering, particularly in optimizing the performance and efficiency of modern vehicles. These gear systems consist of a central sun gear, multiple planet gears, and a ring gear, allowing for compact design and high power density. According to a report by MarketsandMarkets, the global automotive gear market is projected to reach USD 36.4 billion by 2025, with planetary gears contributing significantly to this growth due to their ability to improve torque transfer and reduce weight.

One of the most significant applications of planetary gears in automotive engineering is in automatic transmissions. The ability of planetary gear sets to seamlessly shift between different gear ratios enhances fuel efficiency and driving comfort. A study conducted by the Society of Automotive Engineers (SAE) revealed that vehicles equipped with advanced planetary transmission systems can achieve fuel economy improvements of up to 10-20% compared to traditional manual transmissions. This not only aligns with the industry's push for more sustainable practices but also meets the increasing consumer demand for high-performance and fuel-efficient vehicles.

Advancements in Planetary Gear Design for Robotics

The advancements in planetary gear design for robotics have revolutionized the efficiency and functionality of robotic systems. In modern engineering, these gears offer compact solutions that enable robots to achieve high torque outputs while maintaining a lightweight structure. The unique configuration of planetary gears allows them to distribute load evenly across multiple gears, significantly enhancing durability and reducing wear over time. This is particularly beneficial in robotic applications, where reliability and precise movement are paramount.

The advancements in planetary gear design for robotics have revolutionized the efficiency and functionality of robotic systems. In modern engineering, these gears offer compact solutions that enable robots to achieve high torque outputs while maintaining a lightweight structure. The unique configuration of planetary gears allows them to distribute load evenly across multiple gears, significantly enhancing durability and reducing wear over time. This is particularly beneficial in robotic applications, where reliability and precise movement are paramount.

Recent innovations in materials and manufacturing techniques have further propelled the capabilities of planetary gears in robotics. The incorporation of high-strength alloys and advanced composites has not only improved performance but also expanded operational ranges, allowing robots to perform in increasingly demanding environments. Additionally, the integration of smart technologies, such as sensors and adaptive control systems, has enabled real-time monitoring and adjustment of gear performance, optimizing energy efficiency and responsiveness. These advancements ensure that planetary gears remain a cornerstone in the design and functionality of modern robotic systems, driving their evolution and application across various industries.

Comparative Analysis: Planetary Gears vs. Traditional Gear Systems

Planetary gears and traditional gear systems serve the same fundamental purpose of transmitting motion and torque, yet they do so in markedly different ways, each with its own advantages and drawbacks. Traditional gear systems, comprising spur, bevel, or helical gears, rely on direct contact between gears to transfer power. This simple design often leads to higher noise levels, increased wear, and lower efficiency under high loads due to the axial thrust forces generated. While offering straightforward applications, traditional systems can be bulky and require more space, limiting their use in compact designs.

In contrast, planetary gears feature a unique arrangement where one or more gears (the planets) revolve around a central gear (the sun) while simultaneously rotating on their own axes. This configuration provides several advantages, including a high power-to-weight ratio and increased efficiency due to better load distribution among the gears. Additionally, planetary gear sets can be compact, allowing for reduced size and weight in applications such as automotive transmissions and robotics. The inherent design of planetary systems also facilitates the creation of multi-speed transmissions, offering the versatility needed in modern engineering applications where space and efficiency are paramount.