Metal Forming Market Trends and Insights at the 138th Canton Fair 2025 in China

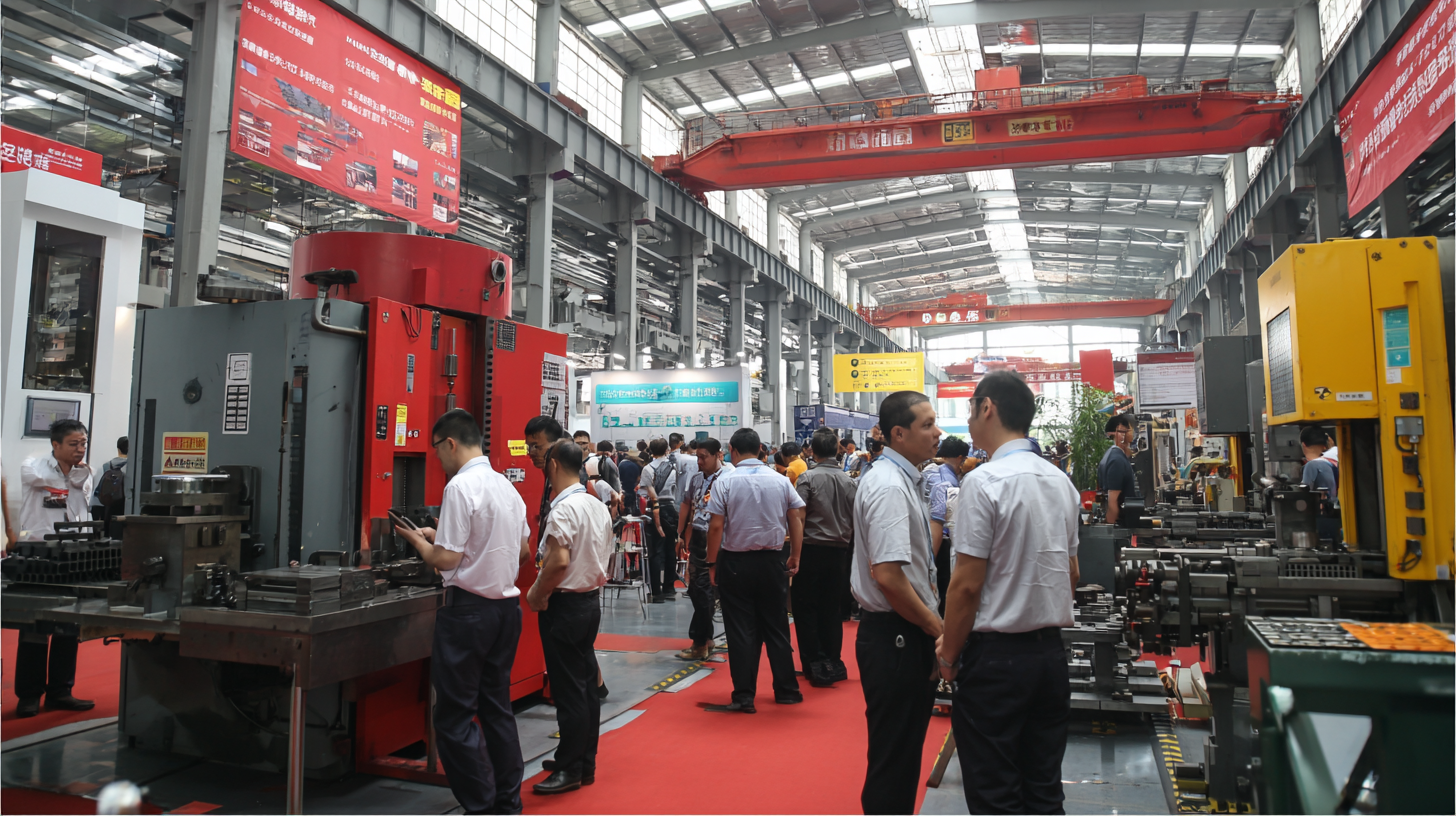

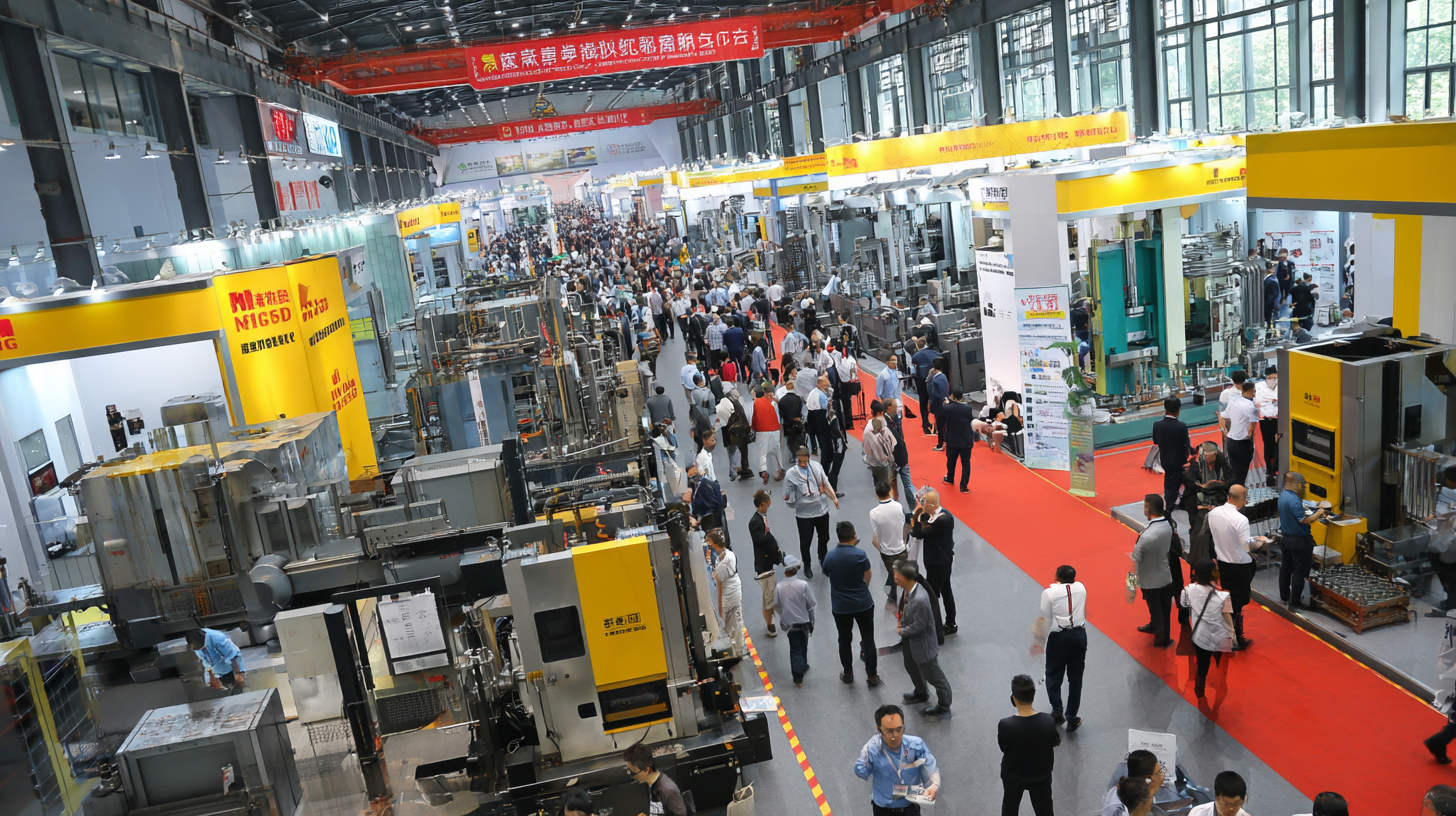

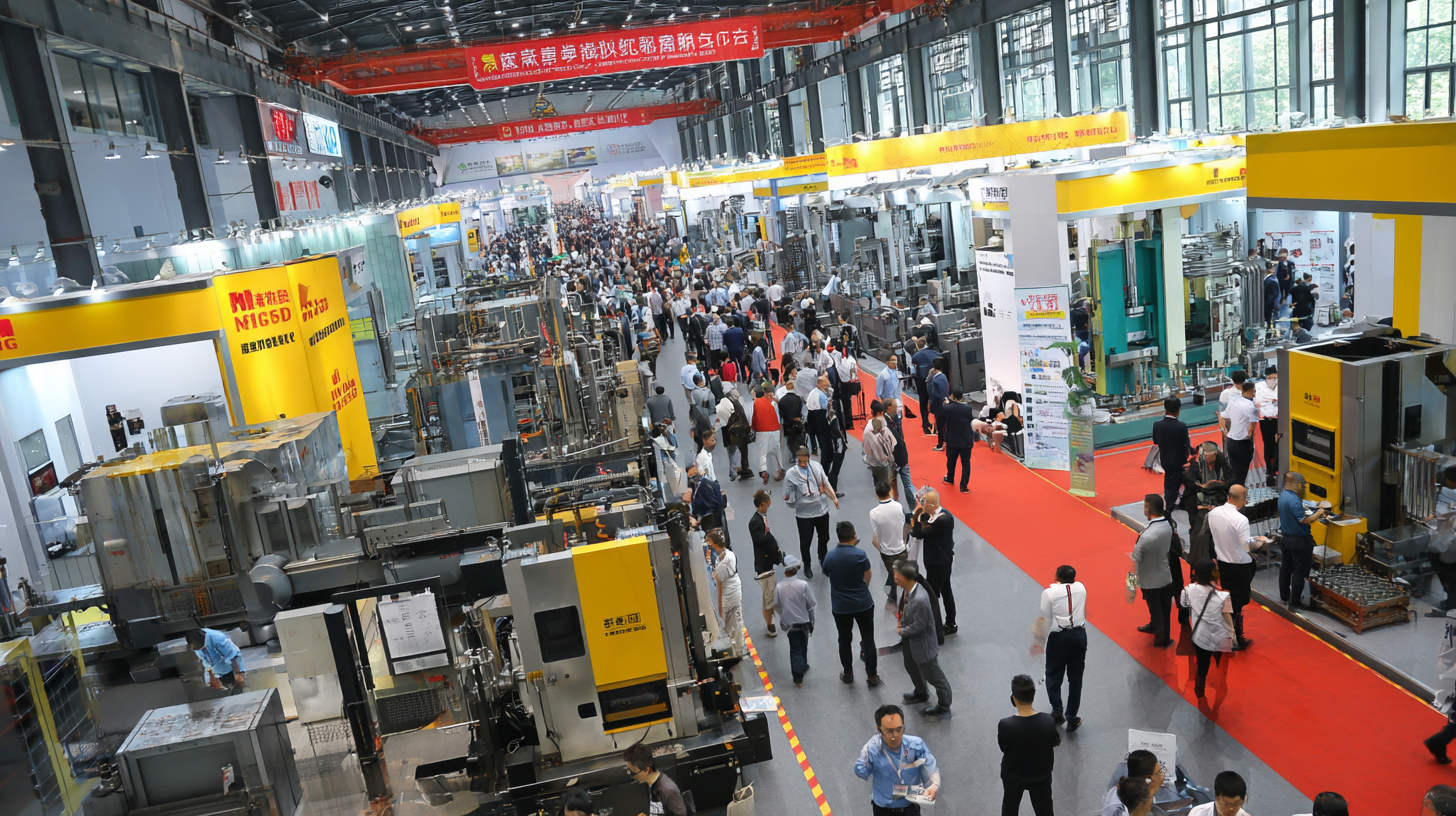

The metal forming industry is experiencing a significant transformation, driven by technological advancements and rising demand across various sectors. At the 138th Canton Fair in 2025, this dynamic market is expected to showcase innovative methodologies and equipment that enhance production efficiency and quality in metal forming processes. According to a recent market report by Mordor Intelligence, the global metal forming market is projected to reach USD 400 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth is largely attributed to the booming automotive and aerospace industries, where precision and reliability in metal components are paramount. The Canton Fair serves as an essential platform for industry professionals to explore emerging trends, establish partnerships, and discuss the future of metal forming technologies, positioning itself as a pivotal event in the global manufacturing landscape.

Emerging Trends in Metal Forming Technologies at the Canton Fair 2025

At the 138th Canton Fair in 2025, emerging trends in metal forming technologies are expected to take center stage, showcasing innovations that could redefine manufacturing processes. With the increasing demand for precision and efficiency, exhibitors will present advanced methodologies that integrate automation and smart technologies. The rise of Industry 4.0 is particularly significant, as the integration of IoT and AI into metal forming processes allows for real-time data analysis and enhanced productivity.

In addition, sustainable practices are becoming crucial in the metal forming sector. Many manufacturers are focusing on eco-friendly materials and energy-efficient processes to reduce their carbon footprint. Technologies such as additive manufacturing and hybrid forming techniques are gaining traction, offering new possibilities for lightweight designs and custom solutions. The Canton Fair will provide a platform for industry leaders to exchange insights on these developments, highlighting the importance of innovation in meeting evolving market needs.

Metal Forming Market Trends and Insights at the 138th Canton Fair 2025 in China

| Trend |

Description |

Impact Level |

Technology Adoption Rate |

Year of Introduction |

| Automation in Metal Forming |

Increased usage of robotic systems for metal forming processes. |

High |

70% |

2023 |

| Sustainability Initiatives |

Focus on energy-efficient processes and recycling of scrap metal. |

Medium |

65% |

2024 |

| Smart Manufacturing Integration |

Integration of IoT and AI for improved precision and quality in metal forming. |

High |

75% |

2023 |

| Advanced Material Usage |

Adoption of lightweight and high-strength materials for better efficiency. |

Medium |

60% |

2022 |

| Customization of Metal Forming Equipment |

Increasing demand for customized solutions tailored to specific client needs. |

High |

80% |

2025 |

Innovative Applications of Metal Forming in Various Industries

The metal forming industry is witnessing significant innovations, particularly in the context of sustainability and advanced manufacturing processes. At the upcoming 138th Canton Fair in 2025, various sectors, including automotive and construction, are expected to showcase cutting-edge applications of metal forming that prioritize environmental efficiency. The recent advancements in sustainable building materials highlight a shift towards innovative production technologies that enhance performance without sacrificing ecological responsibility.

Emerging trends in in-process monitoring methods are transforming how metal components are produced, allowing for real-time adjustments based on factors such as force and temperature. This adaptability improves product quality and reduces waste, making metal forming processes more sustainable. Additionally, the growth of the sheet metal fabrication services market signifies the rising demand for efficient and versatile manufacturing solutions, driven by advancements in digital technologies and robotics. These developments are collectively steering the market towards a future characterized by enhanced productivity and innovative applications across multiple industries.

Trends in Metal Forming Applications Across Various Industries

Key Players and Their Contributions to the Metal Forming Market

The metal forming market is experiencing dynamic growth, with key players significantly impacting the industry's landscape. Companies specializing in advanced metal forming technologies are leading the charge, focusing on innovation and sustainability. As highlighted in recent industry reports, investments in automation and digitalization within the manufacturing process are enhancing efficiency and reducing waste. This trend aligns with the global industrial lasers market, which is projected to expand from $23.90 billion in 2025 to $55.09 billion by 2032, representing a remarkable CAGR of 12.7%. This surge is largely driven by the increasing application of laser technology in metal forming processes.

Moreover, prominent player contributions are pivotal in shaping market trends. Companies are leveraging their expertise to develop sophisticated metal forming solutions that cater to diverse sectors, from automotive to aerospace. Their commitment to research and development is yielding advanced machinery that not only improves product quality but also promotes energy efficiency. As these key players continue to innovate, the metal forming market is poised for resilience and significant advancements, offering promising opportunities for growth and collaboration at events like the 138th Canton Fair in 2025.

Sustainability and Eco-friendly Practices in Metal Forming Industry

The metal forming industry is gradually evolving towards sustainability and eco-friendly practices, especially highlighted during the 138th Canton Fair 2025 in China. According to a 2022 report by Research and Markets, the global metal forming market is projected to reach approximately $300 billion by 2026, with a significant shift towards green technologies. This transition is driven by increasing regulatory pressures and rising consumer demand for sustainable products.

Innovations such as the use of eco-friendly materials and energy-efficient manufacturing processes are gaining traction. For instance, advanced techniques like precision forging and additive manufacturing not only enhance the quality of metal components but also minimize waste and energy consumption. According to the International Energy Agency (IEA), adopting such technologies could reduce energy use in metal forming operations by up to 30% by 2030. Furthermore, many companies are committing to carbon neutrality in their production processes, reflecting a robust industry trend towards sustainability while ensuring economic viability.

Future Forecast: The Growth Potential of Metal Forming Post-Canton Fair 2025

The 138th Canton Fair in 2025 is expected to be a pivotal moment for the metal forming market, showcasing the latest innovations and technologies. As industry leaders gather to unveil breakthroughs, the event will highlight sustainable practices and advanced automation, driving the sector towards a more efficient and eco-friendly future. This provides a unique platform for businesses to network and discuss emerging trends, facilitating collaborations that could reshape the landscape of metal forming.

Post-Canton Fair 2025, the growth potential in the metal forming sector appears robust. With increased demand in automotive, aerospace, and construction, the industry is poised for significant expansion. Companies that leverage the insights gained during the fair could gain a competitive edge by adopting new technologies and methodologies showcased during the event. Moreover, the focus on sustainability and innovation positions the metal forming market to meet the evolving needs of various sectors, ultimately leading to enhanced profitability and market reach in the years to come.