How to Achieve Precision Drive for Enhanced Performance and Efficiency

In today's fast-paced technological landscape, achieving optimal performance and efficiency has become a paramount goal across various industries. One of the pivotal strategies to enhance operational capabilities lies in the implementation of "precision drive" systems. These advanced drive mechanisms not only improve the accuracy of movements and processes but also significantly reduce the likelihood of errors, thereby maximizing productivity.

Precision drive technology incorporates sophisticated algorithms and high-precision components, transforming the way machines perform tasks. By harnessing the power of precision drive, organizations can streamline their workflows, minimize resource waste, and achieve consistent output quality. As industries evolve, understanding the importance of precision in driving performance will be essential for leaders aiming to maintain a competitive edge.

Furthermore, as we delve deeper into the methodologies for achieving precision drive, we will explore its applications and benefits, highlighting how adopting such systems can lead to enhanced operational performance and efficiency. By focusing on precision, organizations not only elevate their production processes but also pave the way for innovation and growth in their respective fields.

Understanding Precision Drive and Its Importance in Performance

Precision drive technology is increasingly recognized for its crucial role in enhancing performance across various industries. By providing accurate control of motion, precision drives enable machines to operate with minimal deviations, which is vital in sectors like manufacturing and robotics. According to a report by the International Federation of Robotics, manufacturers that implement precision drive systems can increase production efficiency by approximately 20% while simultaneously reducing error rates by up to 30%. This improvement in precision leads to better product quality and reduced operational costs, making it a critical aspect of modern industrial operations.

Furthermore, the importance of precision drive becomes evident when considering the growing demand for automation and smart manufacturing. A study published in the Journal of Manufacturing Systems highlighted that integrating precision drives into automation systems improves overall system responsiveness by 25%. This is particularly essential for industries that require rapid adaptation to changing production needs, allowing for both efficiency and flexibility. As companies strive to maintain competitiveness, investing in precision drive technologies can serve as a pathway to achieving operational excellence and meeting the demands of an evolving market landscape.

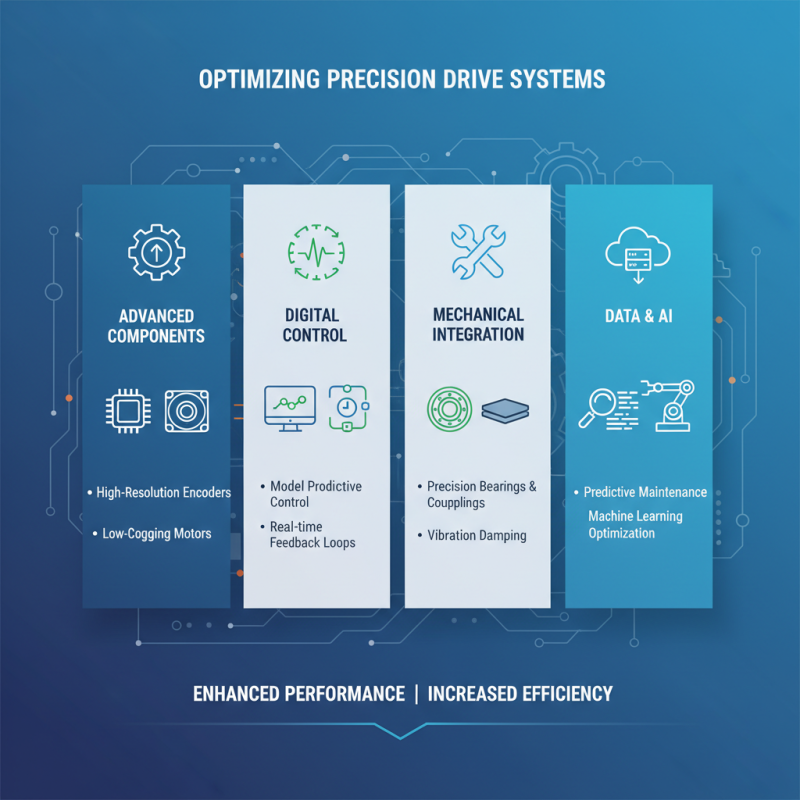

Key Components of Precision Drive Systems for Enhanced Efficiency

Precision drive systems are essential in maximizing performance and efficiency across various applications, from manufacturing to robotics. The key components that make up these systems include high-precision encoders, advanced motor controllers, and robust feedback loops. High-precision encoders provide real-time data about position and speed, ensuring that movements are as accurate as possible. Advanced motor controllers facilitate smooth operation and dynamic adjustments, while feedback loops continuously monitor performance and make necessary corrections.

Tips: To enhance the effectiveness of your precision drive system, consider regularly calibrating your encoders. Calibration ensures that you maintain high accuracy and compensate for any mechanical wear over time. Additionally, investing in quality components and robust software solutions will yield better performance and long-term reliability.

Moreover, integrating smart algorithms for predictive maintenance can significantly reduce downtime. By analyzing system data, these algorithms predict potential failures before they occur, allowing for timely intervention. This proactive approach not only improves efficiency but also extends the lifespan of your precision drive systems.

Precision Drive Systems Performance Metrics

This bar chart illustrates key performance metrics of precision drive systems, highlighting torque, speed, efficiency, and response time, which are essential for enhancing performance and efficiency.

Techniques to Optimize Precision Drive for Improved Performance

Precision drive systems have become essential for industries seeking enhanced performance and efficiency. To optimize precision drive for improved performance, it is crucial to implement a series of effective techniques that address both the technological and operational aspects of these systems.

One of the key techniques is to regularly calibrate your precision drive. This involves checking and adjusting the alignment and accuracy of mechanical components to ensure optimal function. Neglecting calibration can lead to significant inefficiencies and reduced lifespan of the equipment.

**Tip:** Schedule periodic maintenance and calibration checks to identify any discrepancies early and make necessary adjustments to maintain peak performance.

Another important aspect is integrating data analytics into your precision drive operations. By utilizing sensors and monitoring systems, operators can gather real-time data on performance metrics, allowing for proactive adjustments. This not only improves the responsiveness of the system but also aids in predictive maintenance, minimizing downtime.

**Tip:** Invest in robust monitoring tools that provide actionable insights, enabling you to identify trends and make informed decisions that could enhance overall operational efficiency.

Incorporating advanced algorithms and control strategies can also optimize performance. These techniques help in fine-tuning speed and torque settings, ensuring that the drive operates within the most efficient parameters tailored to the specific application.

**Tip:** Explore machine learning approaches to continuously refine your control strategies based on historical performance data, resulting in smarter, more efficient operation over time.

Common Challenges in Implementing Precision Drive Solutions

Implementing precision drive solutions comes with a set of common challenges that organizations must navigate to fully capitalize on the potential benefits. One significant hurdle is the integration of advanced control systems with existing machinery. Many organizations use legacy equipment that may not be compatible with modern precision drive technologies, leading to increased costs and extended downtime during the upgrade process. Ensuring seamless communication between new and old systems is critical, requiring thorough planning and possibly significant modifications to the existing infrastructure.

Another challenge lies in the training and adaptation of the workforce. Precision drive systems often utilize sophisticated analytics and automation features that may be unfamiliar to operators. Without proper training and support, employees may struggle to effectively utilize these tools, hindering productivity and creating frustration. Organizations should invest in comprehensive training programs that not only teach technical skills but also emphasize the importance of precision-driven performance as part of the company’s overall goals. By addressing these challenges head-on, businesses can pave the way for successful implementation of precision drive solutions.

How to Achieve Precision Drive for Enhanced Performance and Efficiency - Common Challenges in Implementing Precision Drive Solutions

| Challenge |

Description |

Potential Solutions |

Impact on Performance |

| Integration with Existing Systems |

Challenges in incorporating new precision drive technologies into legacy systems. |

Conduct a thorough systems review and utilize modular designs. |

Improves compatibility and reduces downtime. |

| Cost Constraints |

High initial investment for precision drive systems may deter implementation. |

Explore financing options and calculate long-term savings. |

Greater efficiency leads to reduced operational costs over time. |

| Training Requirements |

Need for specialized training for personnel to operate new systems effectively. |

Implement comprehensive training programs with hands-on components. |

Enhances workforce capability and operational safety. |

| Data Management |

Handling large volumes of data generated by precision drives can be overwhelming. |

Utilize advanced analytics and big data tools to streamline data processing. |

Improves decision-making and operational adjustments. |

| Maintenance Challenges |

Precision drives may require more frequent and specialized maintenance. |

Establish a routine maintenance schedule and use predictive maintenance tools. |

Minimizes downtime and extends the lifespan of equipment. |

Future Trends in Precision Drive Technology and Their Impact on Industry

As industries strive for greater efficiency and performance, precision drive technology is evolving at a rapid pace. Future trends indicate that advancements in automation and artificial intelligence will play a pivotal role in enhancing precision drive systems. With the integration of smart sensors and machine learning algorithms, these systems will be able to monitor performance in real time, adapt to varying loads, and optimize energy consumption. This flexibility will allow for more precise control over operations, reducing waste and improving overall efficiency.

Moreover, the trend toward electrification and renewable energy sources is set to transform precision drive applications across various sectors. Energy-efficient drive systems will not only contribute to sustainability goals but will also lead to cost savings in energy management. The incorporation of advanced materials and innovative design techniques will further increase the reliability and lifespan of these systems. As industries adopt more sophisticated precision drives, the impact will be felt across manufacturing processes, supply chains, and overall production capabilities, setting the stage for a new era of operational excellence.