Unmatched Quality in China with the Best Integrated Servo Motor Solutions

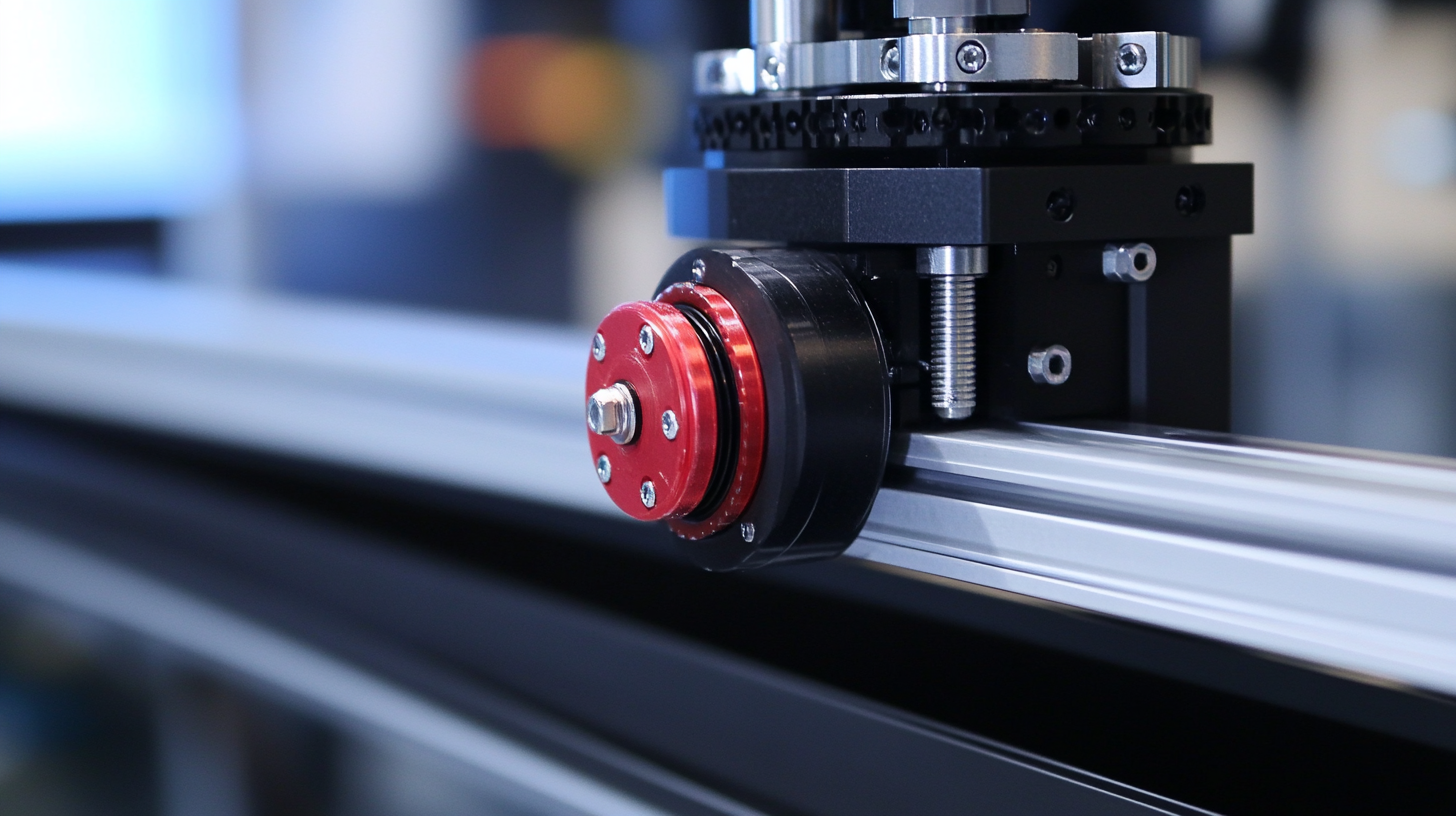

In today's rapidly advancing industrial landscape, the demand for precision and efficiency is at an all-time high. At the heart of this evolution lies the Integrated Servo Motor, a revolutionary solution that embodies unmatched quality and innovation. As China takes center stage in global manufacturing, its commitment to excellence in engineering has propelled it to the forefront of the integrated servo motor industry. With a blend of cutting-edge technology and meticulous craftsmanship, Chinese manufacturers are setting new standards, ensuring that their products not only meet but exceed international expectations. This blog delves into the significance of integrated servo motors, exploring how they enhance automation processes and drive productivity in various sectors, further solidifying China's reputation for delivering world-class solutions across the globe.

In today's rapidly advancing industrial landscape, the demand for precision and efficiency is at an all-time high. At the heart of this evolution lies the Integrated Servo Motor, a revolutionary solution that embodies unmatched quality and innovation. As China takes center stage in global manufacturing, its commitment to excellence in engineering has propelled it to the forefront of the integrated servo motor industry. With a blend of cutting-edge technology and meticulous craftsmanship, Chinese manufacturers are setting new standards, ensuring that their products not only meet but exceed international expectations. This blog delves into the significance of integrated servo motors, exploring how they enhance automation processes and drive productivity in various sectors, further solidifying China's reputation for delivering world-class solutions across the globe.

Characteristics of Different Types of Servo Motors in China

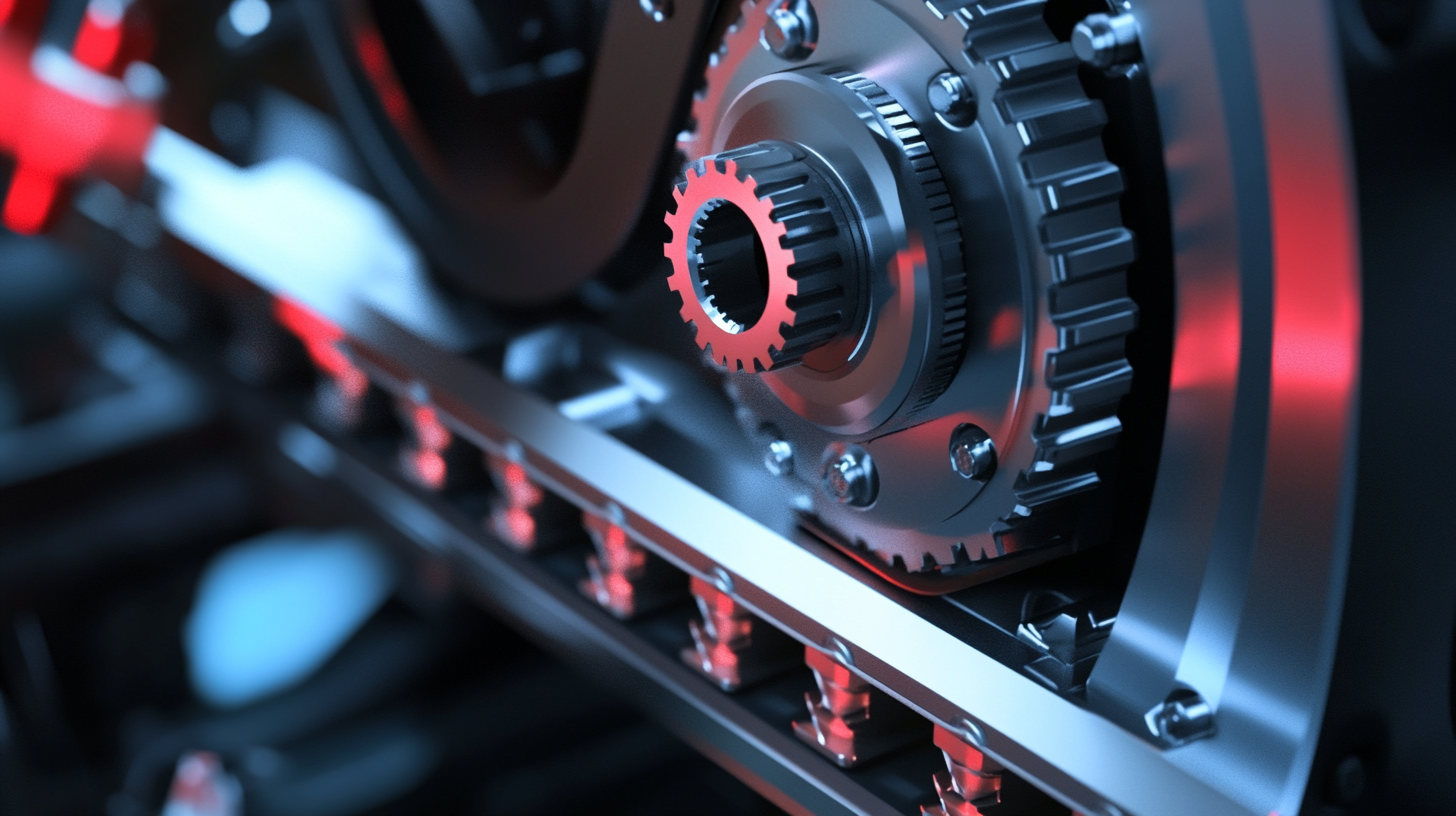

When exploring the characteristics of different types of servo motors in China, two primary categories emerge: AC and DC servo motors. AC servo motors are known for their high performance and versatility, making them suitable for applications requiring precise control, such as robotics and automation systems. On the other hand, DC servo motors offer a simpler construction and are often favored in applications like electric vehicles due to their effective torque and speed control at lower costs.

Tips: When selecting a servo motor for your project, consider the specific requirements of your application. For instance, if you need high speed and precision, an AC servo motor may be more appropriate. In contrast, for simpler or cost-sensitive applications, a DC servo motor might suffice. Additionally, evaluate the voltage requirements—low, medium, or high—as this will significantly impact the performance and compatibility with your system.

Understanding the end-user market is also crucial. The automotive industry, for example, is increasingly adopting integrated servo motor solutions to enhance vehicle performance and automation. By aligning the choice of servo motors with industry demands and specific application needs, manufacturers can optimize their productivity and efficiency.

Unmatched Quality in China - Integrated Servo Motor Types

Applications and Benefits of Integrated Servo Motor Solutions

Integrated servo motor solutions are transforming various industries with their unmatched quality and performance. The global market for integrated servo motors is expected to grow significantly, driven by advances in motion-control technologies. The increasing demand for automation in sectors like automotive, manufacturing, and robotics is propelling market expansion, with AC and DC types being the most favored due to their efficiency and versatility.

According to recent reports, the integrated servo motor market is anticipated to reach USD XX billion by 2027, with a compound annual growth rate (CAGR) of XX% from 2020 to 2027.

Integrated servo motor solutions are transforming various industries with their unmatched quality and performance. The global market for integrated servo motors is expected to grow significantly, driven by advances in motion-control technologies. The increasing demand for automation in sectors like automotive, manufacturing, and robotics is propelling market expansion, with AC and DC types being the most favored due to their efficiency and versatility.

According to recent reports, the integrated servo motor market is anticipated to reach USD XX billion by 2027, with a compound annual growth rate (CAGR) of XX% from 2020 to 2027.

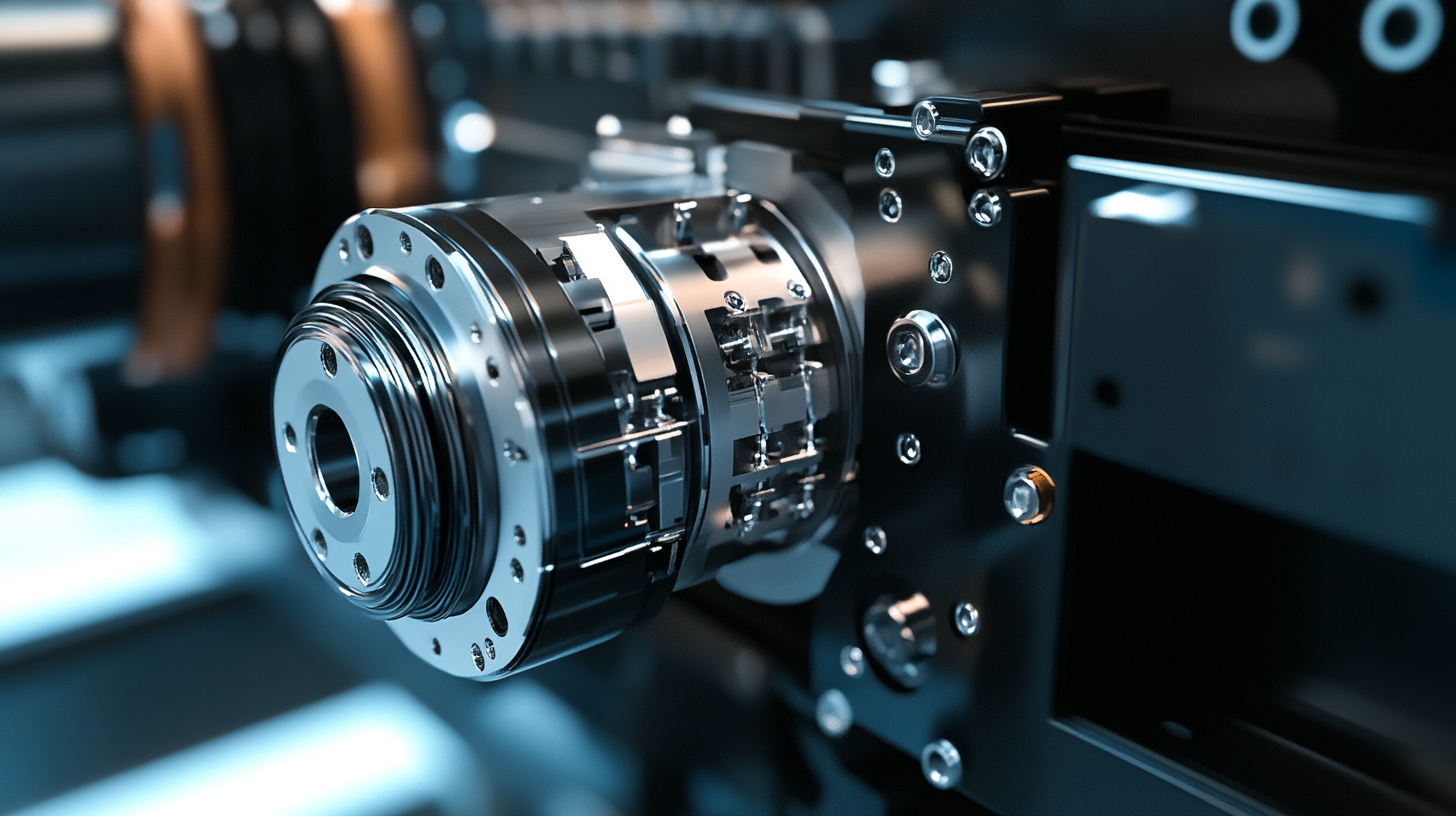

The integration of cutting-edge communication and configuration technologies simplifies the integration process for end-users. Recent innovations have focused on enhancing safety features, with safety-integrated functions becoming essential in modern drive systems to mitigate risks. Additionally, manufacturers are introducing compact solutions like high-torque servo motors equipped with advanced harmonic drives, catering to the rising need for powerful yet space-efficient designs. As automation continues to evolve, the benefits of integrated servo motors, including reduced technology costs and peak performance capabilities, will further solidify their place in the market and drive future developments in diverse applications.

Comparison of Servo Motor Types for Industrial Use

In the realm of industrial automation, the choice between AC and DC servo motors is critical for optimizing performance and efficiency. AC servo motors are widely recognized for their durability, high speed, and low maintenance, making them a popular choice in heavy machinery and robotics. Conversely, DC servo motors offer precise control and are often favored for their simplicity in design and ease of use in applications requiring quick acceleration and deceleration.

In the realm of industrial automation, the choice between AC and DC servo motors is critical for optimizing performance and efficiency. AC servo motors are widely recognized for their durability, high speed, and low maintenance, making them a popular choice in heavy machinery and robotics. Conversely, DC servo motors offer precise control and are often favored for their simplicity in design and ease of use in applications requiring quick acceleration and deceleration.

When considering the use of integrated servo motor solutions, understanding the specific needs of your application is essential. For instance, low-voltage motors are ideal for applications requiring safety and energy efficiency, while medium and high-voltage motors are better suited for high-performance tasks in sectors like automotive and manufacturing. This distinction can significantly impact overall system performance and operational costs.

Tips: Always evaluate the torque and speed requirements prior to selecting a motor type. Additionally, it's beneficial to assess the compatibility of the motor with existing systems to ensure seamless integration. Don't overlook the importance of vendor support and product reliability when making your final decision.

How to Choose the Right Servo Motor for Your Project

When selecting the right servo motor for your project, it's crucial to understand the specific requirements of your application. First, consider the performance characteristics needed—torque, speed, and precision. For instance, if your application demands high speeds and accuracy, a high-performance servo motor with advanced feedback control might be necessary. On the other hand, a basic application may only require a standard motor with moderate specifications. Knowing the performance criteria helps narrow down your options significantly.

Additionally, compatibility with your existing systems is vital. Ensure that the servo motor you choose can integrate seamlessly with your controllers and sensors. Pay attention to the communication protocols and voltage ratings. Moreover, evaluating the quality and reputation of the manufacturer is essential. In China, there are numerous suppliers; therefore, opting for those known for unmatched quality can make a difference in the long-term reliability and efficiency of your project. Always prioritize manufacturers who provide detailed technical support and documentation to aid in the integration process.

Innovative Trends in Servo Motor Technology and Performance

The servo motor technology landscape is rapidly evolving, spurred by innovative trends that enhance performance and efficiency. With the anticipated growth of the servo motors and drives market expected to reach $4.37 billion between 2024 and 2028, the demand for integrated servo motors and brushless motors is climbing. This surge is driven by advancements in technology that cater to industries ranging from automation to AI, particularly in data centers where energy efficiency is paramount. The integration of GaN (gallium nitride) with liquid cooling technologies is set to redefine energy management, making AI-driven systems more sustainable and effective.

Furthermore, the introduction of the silicon carbide axis module alongside multi-axis servo systems is a testament to the industry's focus on robustness and energy efficiency. These developments not only simplify installation but also optimize engineering processes, paving the way for smarter and more responsive motion controls. As servo motor applications expand and diversify, the need for high-performance solutions continues to grow, demonstrating the critical role these technologies play in the future of industrial automation and robotics.

Unmatched Quality in China with the Best Integrated Servo Motor Solutions - Innovative Trends in Servo Motor Technology and Performance

| Parameter | Description | Value |

|---|---|---|

| Torque Output | The maximum continuous torque available from the servo motor | 1.5 Nm |

| Speed Rating | The rated speed at which the motor operates efficiently | 3000 RPM |

| Feedback Type | The method used for position feedback | Absolute Encoder |

| Voltage Rating | The operating voltage for the servo motor | 24 VDC |

| Controller Type | The type of controller used to operate the servo motor | Digital PID Controller |

| Application Area | Common applications for the servo motor | Industrial Automation |