Revolutionizing Efficiency: Innovative Manufacturing Solutions for Modern Industries

In today's rapidly evolving industrial landscape, the quest for efficiency has led to a transformative wave in manufacturing solutions. According to a report by McKinsey, industries that have embraced innovative manufacturing practices can improve their productivity by up to 20%. The integration of digital technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), has been pivotal in optimizing operations and reducing costs.

For example, a study by Deloitte highlights that manufacturers can save an estimated $1.5 trillion through the adoption of smart manufacturing strategies by 2025. As organizations strive to enhance their operational frameworks, the need for cutting-edge manufacturing solutions becomes increasingly critical, driving not only cost efficiency but also the enhancement of product quality and supply chain reliability. Embracing these advancements is essential for industries looking to maintain competitiveness in a market that demands

agility and innovation.

For example, a study by Deloitte highlights that manufacturers can save an estimated $1.5 trillion through the adoption of smart manufacturing strategies by 2025. As organizations strive to enhance their operational frameworks, the need for cutting-edge manufacturing solutions becomes increasingly critical, driving not only cost efficiency but also the enhancement of product quality and supply chain reliability. Embracing these advancements is essential for industries looking to maintain competitiveness in a market that demands

agility and innovation.

Identifying Key Processes for Streamlined Manufacturing Efficiency

In the pursuit of streamlined manufacturing efficiency, modern industries are increasingly focusing on key processes that can significantly enhance productivity. According to a report by McKinsey, companies that implement advanced manufacturing technologies can see a productivity increase of up to 20-30%. This improvement is largely due to the adoption of automation and data analytics, which allow businesses to identify bottlenecks and optimize workflows in real-time. By centering attention on processes such as supply chain integration and lean manufacturing principles, organizations can minimize waste and improve resource management.

Moreover, a study from Deloitte indicates that manufacturers who embrace innovative solutions like additive manufacturing and IoT-enabled devices can reduce production costs by as much as 15%. These technologies enable a shift towards more flexible production lines, allowing companies to quickly adapt to market changes and customer demands. By focusing on the optimization of critical processes, industries are not only driving efficiency but also positioning themselves to be more competitive in a rapidly evolving market landscape.

Revolutionizing Efficiency: Manufacturing Processes Overview

Leveraging Automation Technologies to Enhance Production Speed

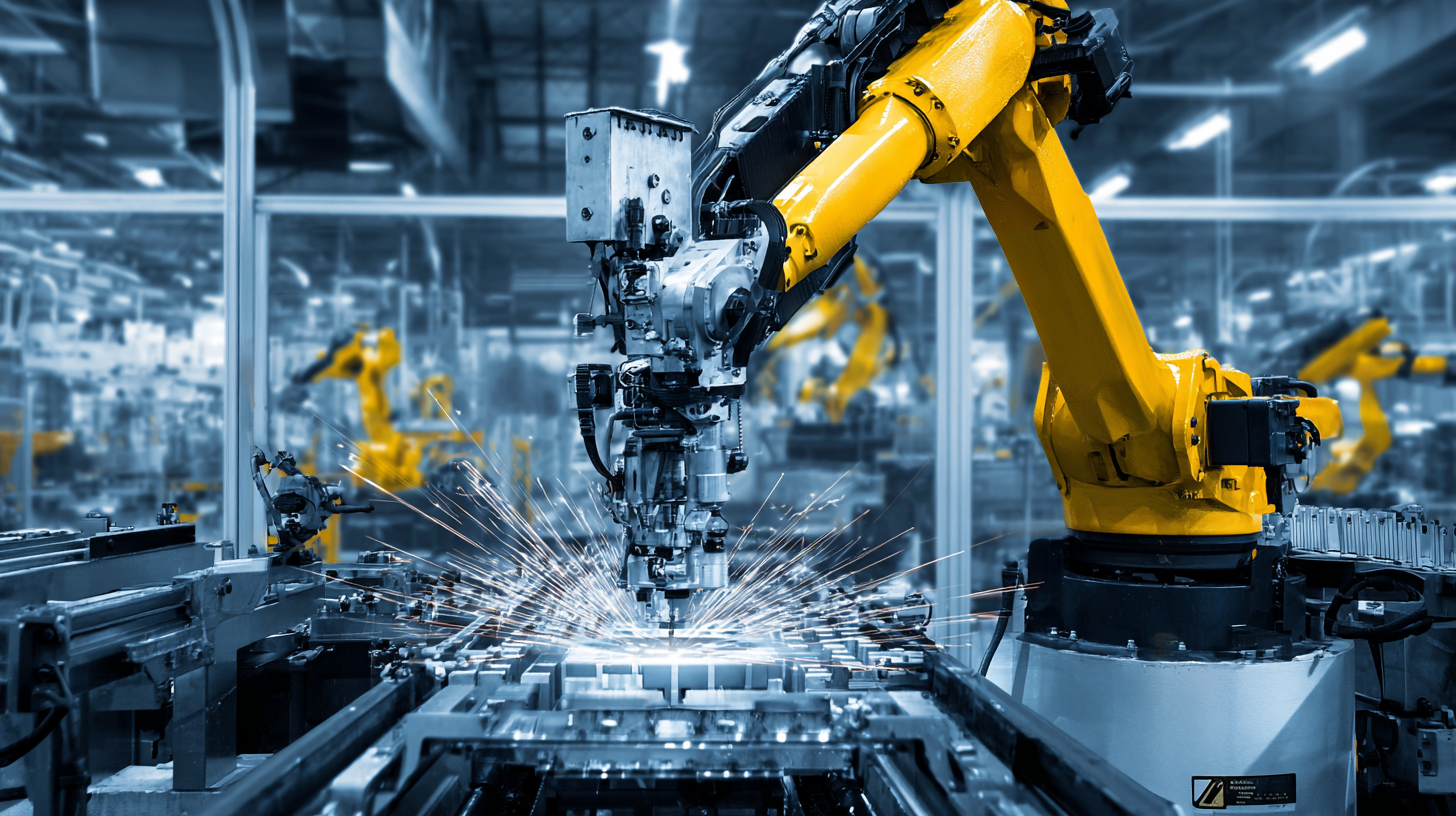

In today's competitive landscape, industries are increasingly turning to automation technologies to enhance production speed and operational efficiency. According to the McKinsey Global Institute, up to 45% of current work activities can be automated, which presents a significant opportunity for manufacturers to streamline processes. By implementing robotic process automation (RPA) and smart manufacturing systems, companies can achieve drastic reductions in production time, leading to faster time-to-market and improved responsiveness to consumer demands.

Moreover, a report by the International Federation of Robotics reveals that the global sales of industrial robots have been surging, expected to reach 3.3 million units by 2025. These robots not only improve precision and reliability in manufacturing but also reduce downtime and labor costs. For instance, a study by Deloitte found that companies adopting automation saw a 20-30% increase in productivity.

This transformation in the manufacturing sector through automation technologies is not just a trend; it is a strategic move that can define the success and sustainability of modern industries in the years to come.

Implementing Data-Driven Decision Making for Continuous Improvement

In today's fast-paced industrial landscape, implementing data-driven decision-making has become crucial for achieving continuous improvement. Modern manufacturing solutions are now leveraging advanced technologies, including AI and data analytics, to enhance operational efficiency and responsiveness. For instance, companies are increasingly integrating knowledge graphs with generative AI to optimize processes and improve incident response times dramatically, as evidenced by a notable increase in efficiency among platforms designed for security and risk management.

Tips: To effectively harness the power of data, organizations should invest in robust data governance frameworks that ensure data quality and accessibility. Establishing a culture of data observability can empower teams to make informed decisions, driving productivity and innovation.

Furthermore, as industries shift from traditional labor-dependent models to knowledge-driven approaches, it is essential for businesses to embrace intelligent manufacturing processes. This includes adopting smart technologies that not only streamline production but also facilitate real-time data analytics to inform strategic choices. By focusing on data-driven methodologies, companies can better navigate the complexities of modern manufacturing challenges and seize opportunities for growth.

Exploring Sustainable Practices in Innovative Manufacturing

In today's rapidly evolving manufacturing landscape, the integration of sustainable practices is becoming increasingly essential. Innovative manufacturing solutions are not just about enhancing productivity and efficiency; they also emphasize environmental responsibility. By adopting eco-friendly materials and processes, industries can reduce waste and lower their carbon footprint. Techniques such as additive manufacturing and closed-loop systems are gaining traction, enabling companies to recycle materials and minimize the extraction of new resources.

Moreover, the move towards sustainability in manufacturing fosters a culture of innovation. Companies are not only seeking to comply with regulatory requirements but are also recognizing the competitive advantage that green practices bring. Implementing sustainable technologies, such as energy-efficient machinery and renewable energy sources, helps to decrease operational costs in the long term. As industries increasingly prioritize sustainability, they are likely to attract environmentally conscious consumers, positioning themselves as leaders in the modern market.

Integrating Advanced Robotics for Precision and Flexibility in Production

The integration of advanced robotics in manufacturing has become a game changer for modern industries, offering unprecedented levels of precision and flexibility in production processes. With the rise of automation, robots are increasingly taking on complex tasks that require a high degree of accuracy, which helps minimize errors and enhances product quality. These robotic systems are not only designed to perform repetitive tasks but can also adapt to various production requirements, allowing manufacturers to swiftly change their output based on market demands.

Moreover, the application of advanced robotics contributes to a more efficient production line. Collaborative robots, or cobots, work alongside human operators, enabling a seamless blend of human intelligence and robotic precision. This partnership enhances workflow efficiency, reduces downtime, and increases overall productivity. As industries embrace these innovative manufacturing solutions, they are not only streamlining operations but also positioning themselves to be more competitive in a rapidly evolving market landscape. The future of manufacturing lies in leveraging these technologies to achieve operational excellence and sustainable growth.

Revolutionizing Efficiency: Innovative Manufacturing Solutions for Modern Industries - Integrating Advanced Robotics for Precision and Flexibility in Production

| Aspect |

Description |

Impact on Manufacturing |

Example Technology |

| Process Automation |

Using robots to perform repetitive tasks |

Increases speed and reduces human error |

Collaborative Robots (Cobots) |

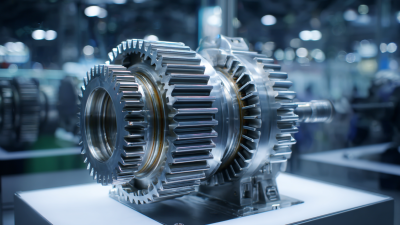

| Precision Engineering |

High-accuracy machining and assembly |

Enhances quality control and product reliability |

Robotic Arms with High Precision |

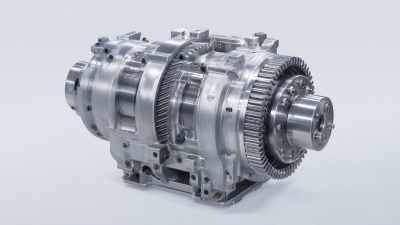

| Flexible Manufacturing Systems |

Systems that can adapt to changes in production |

Reduces downtime and increases responsiveness |

Modular Automation Platforms |

| Data-Driven Decision Making |

Using analytics to guide operations |

Improves operational efficiency and productivity |

Machine Learning Algorithms |

| Supply Chain Integration |

Streamlining logistics and inventory management |

Minimizes delays and costs |

Internet of Things (IoT) Solutions |

For example, a study by Deloitte highlights that manufacturers can save an estimated $1.5 trillion through the adoption of

For example, a study by Deloitte highlights that manufacturers can save an estimated $1.5 trillion through the adoption of