Revolutionizing Manufacturing: How Industrial Automation Solutions Drive Efficiency and Innovation

In today's rapidly evolving industrial landscape, companies are increasingly turning to

industrial automation solutions to enhance productivity and foster innovation.

According to a report by McKinsey, organizations that adopt automation at scale can improve productivity by up to

20-25%, significantly reducing operational costs and lead times.

Additionally, the International Federation of Robotics highlights that the global market for industrial robots is projected to reach

$95 billion by 2025, underscoring the growing reliance on automated systems.

By integrating advanced technologies such as artificial intelligence and

the Internet of Things into manufacturing processes, businesses not only streamline operations but also pave the way for

the development of smarter, more responsive production environments.

This article explores the transformative power of industrial automation solutions, demonstrating how they drive efficiency and innovation in manufacturing.

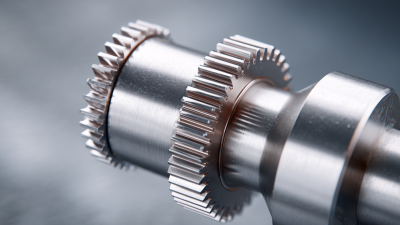

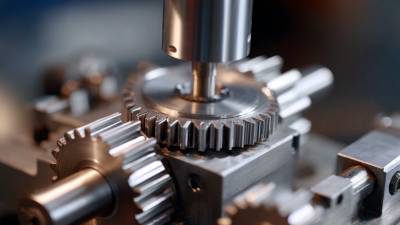

Harnessing Robotics to Enhance Production Speed and Precision

In today's fast-paced industrial landscape, robotics plays a pivotal role in enhancing production speed and precision. By integrating robotic systems into manufacturing processes, companies can vastly improve efficiency, reduce error rates, and accelerate output. These intelligent machines are capable of performing intricate tasks with unparalleled accuracy, thereby minimizing the need for manual intervention and allowing human workers to focus on more strategic functions.

The implementation of robotics also fosters innovation within manufacturing industries. With advanced automation solutions, businesses can experiment with new production techniques and optimize workflows to meet evolving market demands. The adaptability of robots allows for customization and rapid changeovers, ensuring that production lines can pivot quickly in response to customer needs. As a result, manufacturers harness the power of robotics not only to enhance their current capabilities but also to drive continuous improvement and foster a culture of innovation.

Integrating IoT Technologies for Real-Time Monitoring and Control

The integration of IoT technologies in industrial automation is transforming manufacturing by enhancing real-time monitoring and control. According to a recent report, the global market for IoT in smart building automation is expected to grow significantly, reflecting an increasing demand for connected devices that streamline operations and improve efficiency. By utilizing real-time data collection and analysis, industries can achieve faster decision-making processes and minimize downtime.

One key area of this transformation is seen in the burner management systems utilized in boilers and other combustion equipment. These systems ensure safe startup, operation, and shutdown by preventing unsafe operational conditions. As companies adopt IoT-based solutions, predictive maintenance powered by digital twins becomes possible. This technology allows businesses to forecast equipment behavior, reducing the risk of failures and increasing overall productivity. An industry analysis highlights that the market for process control systems is set to grow significantly, with a projected compound annual growth rate (CAGR) of around 5% from 2025 to 2033, which underscores the vital role that IoT plays in enhancing operational efficiency.

Revolutionizing Manufacturing: How Industrial Automation Solutions Drive Efficiency and Innovation - Integrating IoT Technologies for Real-Time Monitoring and Control

| Dimension |

Description |

Impact (%) |

Implementation Time (Months) |

| Automation of Production Lines |

Implementing automated systems for assembly and manufacturing processes |

20% |

6 |

| Real-Time Data Monitoring |

Using IoT devices to track production metrics in real-time |

15% |

4 |

| Predictive Maintenance |

Utilizing AI to predict equipment failures before they occur |

30% |

8 |

| Supply Chain Optimization |

Improving material flow and logistics using IoT systems |

25% |

5 |

| Quality Control Systems |

Automated inspection and quality assurance through sensors |

18% |

7 |

Maximizing Data Analytics for Predictive Maintenance and Optimization

The integration of digital twin technology within industrial automation is profoundly transforming manufacturing processes. By leveraging enhanced simulation designs and high-resolution modeling, companies are now able to achieve unprecedented precision in their manufacturing operations. According to a report by McKinsey, digital twin implementations can potentially reduce maintenance costs by 10-20% while increasing productivity by 10-15%. Such advancements enable innovative applications in product design and process optimization, facilitating a more adaptive and efficient manufacturing environment.

Furthermore, the rise of general artificial intelligence is poised to drive the high-quality development of the manufacturing sector. As noted in recent industry analyses, the deployment of AI-driven solutions not only streamlines operations but also fosters an agile response to market demands. With predictive maintenance models, manufacturers are able to anticipate equipment failures and optimize their production schedules accordingly, thus enhancing overall operational efficiency. These strategies are becoming essential for companies, particularly in the face of rapid technological evolution and changing regulatory landscapes, including the global push for carbon neutrality, which presents both challenges and opportunities in the refinery and petrochemical sectors.

Streamlining Workflows with Smart Manufacturing Solutions

In today's fast-paced manufacturing environment, smart manufacturing solutions are transforming workflows by seamlessly integrating industrial automation technologies. These innovative systems not only streamline processes but also enhance productivity by minimizing downtime and optimizing resource allocation. By leveraging real-time data and advanced analytics, manufacturers can make informed decisions that drive efficiency and reduce operational costs.

Tips: To maximize the benefits of smart manufacturing, consider implementing a phased approach to automation. Start with small, manageable projects to assess the technology's impact on your workflows. Additionally, investing in employee training ensures that your workforce is adept at using new technologies, fostering a culture of innovation and adaptability.

As companies adopt advanced automation solutions, they discover new opportunities for innovation. For instance, predictive maintenance powered by IoT sensors can anticipate equipment failures before they occur, allowing for proactive measures that prevent costly interruptions. The key is to embrace a continuous improvement mindset, where ongoing evaluation and refinement of workflows lead to sustained excellence and competitive advantage.

Tips: Regularly review your automation strategies and gather feedback from employees to identify bottlenecks and areas for improvement. Staying agile and open to change will enable your organization to thrive in the rapidly evolving landscape of smart manufacturing.

Empowering Workforce: Training and Upskilling in an Automated Era

As industrial automation continues to evolve, the necessity for a skilled workforce has never been more pronounced. According to a report by the World Economic Forum, by 2025, automation could displace 85 million jobs globally, but it is also expected to create 97 million new roles that require advanced skills. This shift highlights the critical need for training and upskilling initiatives to prepare workers for the emerging job landscape.

Companies are now investing heavily in reskilling programs to empower their workforce. A McKinsey report indicates that organizations that invest in employee development not only enhance their productivity but also see a significant increase in employee engagement. By integrating automation technology with targeted training, businesses can transform their teams into versatile assets capable of navigating the complexities of modern manufacturing environments. This approach not only fosters innovation but also ensures that workers are equipped with the knowledge to operate and manage new automated systems effectively.