Understanding Strain Wave Gear Technology for Innovative Robotics Applications

In recent years, the robotics industry has witnessed remarkable advancements, particularly in the realm of precision movement and efficiency, driven largely by the integration of strain wave gear technology. Strain wave gears, known for their compact size and high torque-to-weight ratios, have become increasingly essential in applications ranging from industrial automation to medical robotics. According to a report by Grand View Research, the global robotics market is projected to reach USD robotic arms but also improves overall design efficiency with reduced weight and size. With their unique capabilities, strain wave gears enable engineers to innovate and optimize robotic systems, meeting the growing demand for more agile and capable machines across various sectors. This article explores the fundamentals of strain wave gear technology and its transformative impact on robotics, offering a step-by-step guide to harnessing its potential for innovative applications.

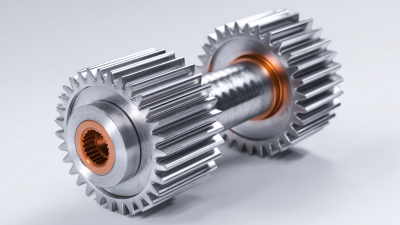

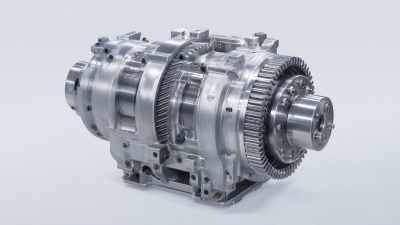

Strain Wave Gears: Revolutionizing Precision Engineering in Robotics

The advancement of strain wave gear technology is creating significant ripple effects in the field of precision engineering, particularly within robotics. Strain wave gears, known for their unique design and superior performance, provide high gear reduction ratios while maintaining compact size and lightweight properties. According to a market analysis by ResearchAndMarkets, the strain wave gear market is expected to grow from $1.2 billion in 2022 to over $2.4 billion by 2028, indicating their increasing adoption in robotics applications.

One of the most revolutionary aspects of strain wave gears is their ability to achieve high positional accuracy and repeatability, which are crucial for robotic systems used in delicate tasks like surgical operations or complex assembly processes. A report by Market Insider highlighted that robotic surgery systems, which often utilize high-precision gear technologies, are projected to surpass $20 billion in market value by 2026, further underscoring the importance of innovations like strain wave gears. By providing engineers with precise motion control and reducing backlash, these gears are poised to enhance the functionality and reliability of various robotic platforms, driving forward innovative solutions in automated environments.

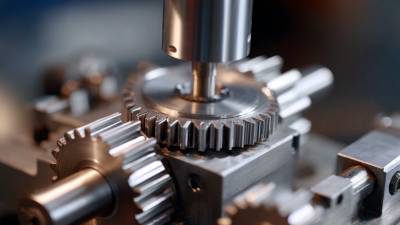

Analyzing the Efficiency of Strain Wave Gear Systems in Modern Robotics

Strain wave gear systems have emerged as a pivotal technology in the realm of modern robotics, particularly due to their unique capability to provide high torque output in a compact size. As per a recent industry report by MarketsandMarkets, the global market for robotic gears is expected to reach $2.4 billion by 2027, driven largely by advancements in automation and robotics. These gear systems are notably efficient, displaying a reduction in backlash and higher precision in motion control—attributes that are essential for robotic applications, from industrial arms to autonomous vehicles.

One of the key advantages of strain wave gears is their ability to maintain efficiency even under heavy loads. Studies indicate that these systems can operate with up to 90% efficiency, significantly outperforming traditional gear systems that often experience energy losses due to friction and backlash. This efficiency translates directly into enhanced performance and longevity of robotic systems, making them ideal for tasks requiring tight tolerances and rapid movements.

Tips: When considering integrating strain wave gear technology into your robotics applications, evaluate the specific torque and space requirements early in the design process. Additionally, pay attention to the gear's mounting alignment to maximize performance and minimize wear. Understanding these factors can significantly enhance the reliability of your robotic systems.

Key Advantages of Strain Wave Gear Technology Over Traditional Mechanical Systems

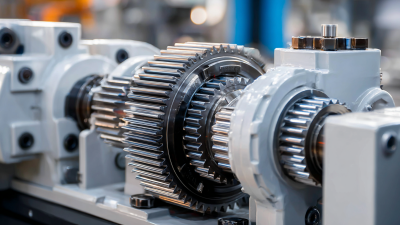

Strain wave gear technology is revolutionizing the field of robotics by offering unique advantages over traditional mechanical systems. One of the primary benefits is its compact design, which allows for a higher power-to-weight ratio. This feature is critical in applications where space is limited, enabling more versatile robot configurations. Additionally, the precision of strain wave gears facilitates smoother and more accurate movements, essential for tasks that require fine control.

Another significant advantage is the reduced backlash inherent in strain wave gears. In traditional gear systems, backlash can lead to inefficiencies and inaccuracies, especially in high-precision applications. However, strain wave gears minimize this issue, providing greater repeatability and reliability in robotic operations. Moreover, the operational lifespan of strain wave gears is often extended due to their unique design, which reduces wear and tear over time. This durability translates to lower maintenance costs and improved long-term performance in various robotic systems.

Market Trends: Growth Projections for Robotics with Strain Wave Gear Integration

The integration of strain wave gear technology in robotics is poised for significant growth, driven by increasing demand for precision and compact mechanical solutions. According to a recent report by MarketsandMarkets, the global robotics market is expected to reach approximately $214 billion by 2025, with a compound annual growth rate (CAGR) of 26% from 2020 to 2025. This surge is largely attributed to advancements in automation and the growing adoption of robots across various sectors, including manufacturing, healthcare, and logistics.

Strain wave gears, known for their unique design and superior performance characteristics, are becoming essential components in modern robotic systems. They offer high torque output, reduced weight, and compact form factors, making them ideal for intricate robotic applications. A report by Technavio highlights that the strain wave gear market for robotics is expected to grow by over $400 million between 2021 and 2025, reflecting the increasing need for efficient mechanical systems that enhance the capabilities of robotic devices. This trend illustrates a clear alignment between technological innovation and market demand, suggesting that businesses investing in strain wave gear integration will benefit from enhanced operational efficiencies and competitive advantages.

Understanding Strain Wave Gear Technology for Innovative Robotics Applications - Market Trends

| Year |

Global Market Size (Million USD) |

Growth Rate (%) |

Key Applications |

Region |

| 2023 |

450 |

8.5 |

Robotic Arms, Automated Guided Vehicles |

North America |

| 2024 |

487 |

8.2 |

Collaborative Robots, Drones |

Europe |

| 2025 |

525 |

7.8 |

Industrial Automation, Medical Robots |

Asia-Pacific |

| 2026 |

565 |

7.5 |

Logistics Robots, Search and Rescue Robots |

Latin America |

| 2027 |

608 |

7.3 |

Construction Robots, Agricultural Robots |

Middle East & Africa |

Case Studies: Successful Implementations of Strain Wave Gears in Robotic Applications

Strain wave gear technology, particularly in the form of bulk metallic glasses (BMGs) used as flexsplines, is gaining traction for its cost-effectiveness and performance in high-performance robotics. Recent collaborations in the field have demonstrated successful implementations in active exoskeletons, showcasing the advantages of miniaturized actuators. The integration of innovative materials not only reduces weight but also enhances the efficiency of robotic systems, which is crucial for applications that require precise movements and agility.

When considering the adoption of strain wave gears in robotics, engineers should focus on the compatibility of the gear with existing systems. It’s essential to assess not just the performance metrics but also how these gears can be integrated seamlessly into different robotic applications.

Tips: Prioritize the selection of materials that can withstand the demands of your specific robotics application. Additionally, stay updated on workshops and seminars focused on the latest advancements in strain wave gear technology to ensure you remain at the forefront of innovation in the field.

Performance Metrics of Strain Wave Gears in Robotics