Essential Tips for Choosing the Right Machine Tool?

Choosing the right machine tool is crucial for any manufacturing setup. The right tool can enhance productivity, improve precision, and reduce costs. However, the process can be overwhelming. Each project may require different machinery, and understanding specifications is essential.

When considering a machine tool, factors like size, capability, and power come into play. It's not just about buying the most advanced version. Sometimes, a simpler tool fits the job better. You might find that overcomplicating your choice leads to inefficiencies. Take time to assess your specific needs and workflow.

Don’t underestimate the importance of user experience. A tool that seems perfect on paper might not feel right in practice. Testing different options can reveal hidden benefits or drawbacks. Ultimately, the decision should balance quality and budget while ensuring it aligns with your production goals. Think critically about your choices; reflection can lead to better outcomes.

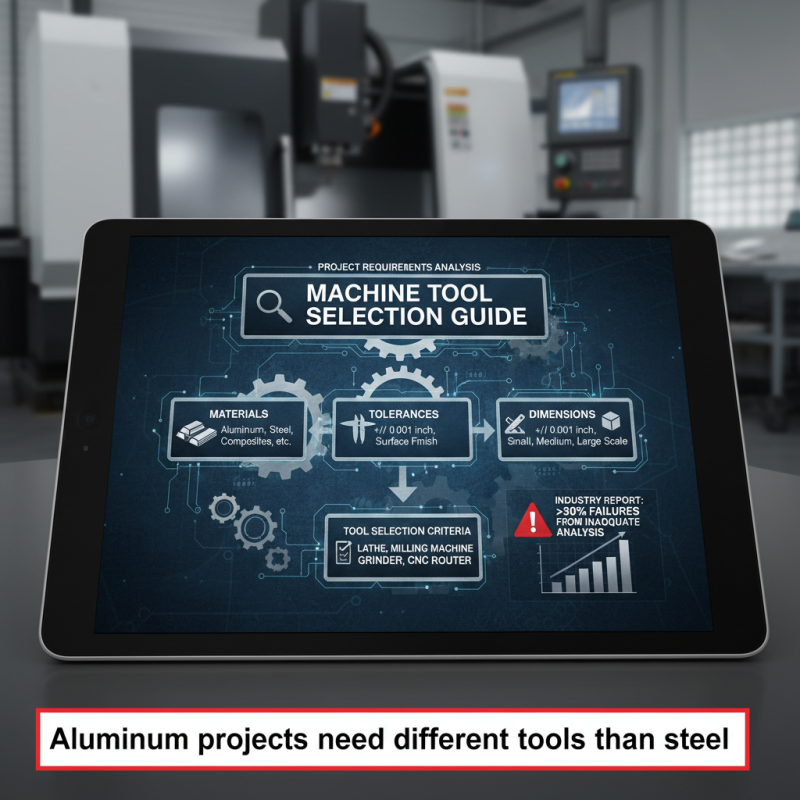

Understanding Your Project Requirements for Machine Tools

Choosing the right machine tool begins with a deep understanding of your project requirements. Different projects have unique demands, and this influences the selection process. According to industry reports, over 30% of machine tool failures arise from inadequate requirements analysis. Assess the materials, tolerances, and dimensions you will work with. For instance, a project focusing on aluminum might require different tools than one involving steel.

One key tip is to define your production volume. Are you running a short batch or large-scale production? This decision will affect the kind of tool you need. For smaller projects, manual or semi-automated tools may suffice. In contrast, high-volume tasks often benefit from CNC machines.

Consider the level of precision required. Industry data suggests that tools that offer higher precision also come with higher initial costs. Evaluate if this is feasible for your budget. Often, businesses underestimate the long-term returns on investing in quality tools.

Lastly, ensure you assess the tool's ease of use. A complex setup may lead to downtime, affecting your workflow. Understanding these aspects can guide you in making a more informed decision while avoiding common pitfalls in tool selection.

Evaluating Different Types of Machine Tools Available

Choosing the right machine tool can significantly influence production quality and efficiency. Different types of machine tools cater to specific machining needs. According to the International Federation of Robotics, the global machine tool market is expected to reach $100 billion by 2025. This growth reflects the increasing demand for advanced manufacturing technologies.

When evaluating machine tools, consider the type of materials you will be working with. For hard metals, CNC lathes may be essential. For softer materials, milling machines can offer versatility. It's crucial to assess your production scale, as some tools are better suited for high-volume production while others excel in low-volume, custom work.

Tip 1: Always calculate the total cost of ownership. This includes energy consumption, maintenance, and tool wear over time. A tool may be cheaper upfront but costly in the long run.

Tip 2: Look for machines with precision and repeatability. These factors greatly impact the final product. However, be aware that high-precision machines often come with a learning curve.

Sometimes, the finest tools could lead to overproduction or unnecessary complication. Not all operations require the latest technology. Simple solutions may suffice. Reflecting on your unique production demands is always wise before making a decision.

Key Features to Look for When Selecting a Machine Tool

When selecting a machine tool, understanding its key features is vital. Precision is paramount. Reports indicate that machining accuracy can impact product quality by as much as 30%. A tool that maintains tight tolerances can significantly reduce waste. This is crucial in competitive industries where margins are tight. Vibrations during operation can compromise accuracy, so a stable design is essential.

Power and speed are equally important. Machining operations often demand high RPMs, which allows for efficient material removal. According to industry data, tools with higher spindle speeds can enhance productivity by up to 50%. However, this can also lead to faster wear and tear. Users must consider longevity and the potential for increased maintenance costs with higher speed machines.

Additionally, ease of use cannot be overlooked. Complex controls can slow down operations and increase error rates. A user-friendly interface minimizes training time. However, features that seem intuitive may also lack advanced functionalities that could enhance efficiency. Balancing simplicity with capability is a challenge. Understanding these factors is essential for making informed decisions in machine tool selection.

Key Features to Look for When Selecting a Machine Tool

Considering Budget and Cost of Ownership Factors

Choosing the right machine tool requires careful consideration of budget. It's essential to look beyond the initial purchase price. Think about the total cost of ownership. This includes maintenance, operation, and even potential downtime costs. A cheaper machine might seem attractive, but its long-term expenses could outweigh the savings.

Consider how often you will use the machine. Frequent use can lead to wear and tear. You may need to invest more in quality tools that can handle heavy workloads. Reflect on your production needs. A versatile machine may cost more upfront, but it could save money in the long run. Remember, hidden costs can arise from operating inefficiencies.

Don't ignore training costs. New tools might require specialized skills. This means additional investments in employee training. If the team isn’t well-prepared, productivity could suffer. Always think critically about the total budget, including all these factors. It's not just about the price tag; it’s about the overall value and return on investment.

Essential Tips for Choosing the Right Machine Tool - Considering Budget and Cost of Ownership Factors

| Machine Tool Type |

Initial Cost ($) |

Annual Maintenance Cost ($) |

Energy Consumption (kWh/year) |

Expected Lifespan (Years) |

Total Cost of Ownership ($) |

| CNC Lathe |

$50,000 |

$3,000 |

1,200 |

10 |

$80,000 |

| Milling Machine |

$45,000 |

$2,500 |

1,000 |

8 |

$65,000 |

| 3D Printer |

$25,000 |

$1,200 |

500 |

5 |

$36,000 |

| Injection Molding Machine |

$60,000 |

$4,500 |

1,500 |

15 |

$115,000 |

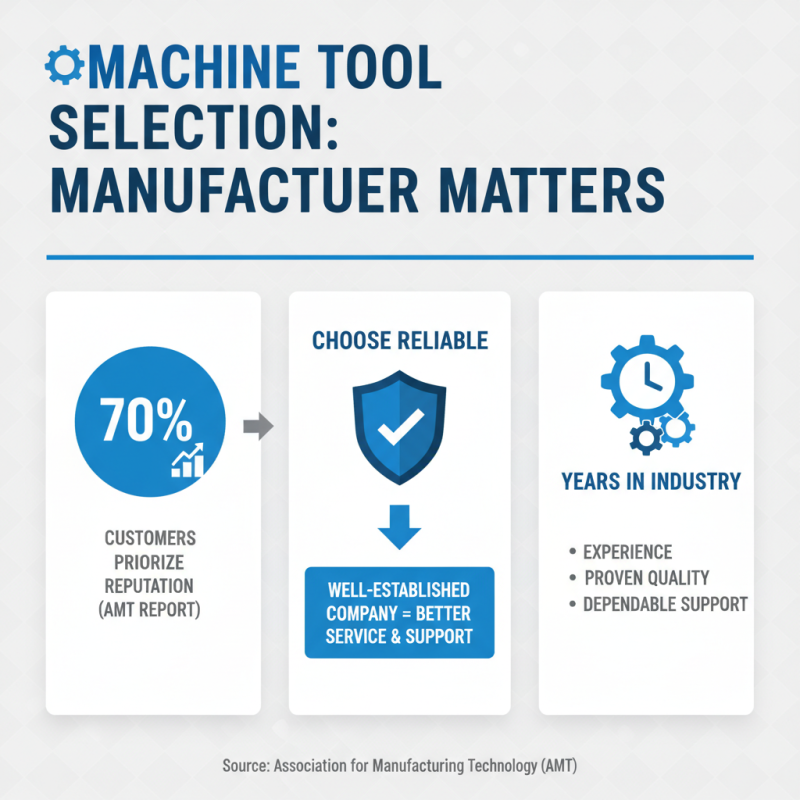

Researching Manufacturers and Comparing Customer Reviews

When selecting a machine tool, researching manufacturers is crucial. A report from the Association for Manufacturing Technology (AMT) highlights that approximately 70% of machine tool customers prioritize manufacturer reputation. This underscores the importance of choosing a reliable source. Look for manufacturers that have been in the industry for several years. A well-established company often means better service and support.

Customer reviews play a significant role in the decision-making process. According to a survey by TechTarget, 62% of buyers read online reviews before making a purchase. Gathering multiple reviews helps gauge the performance and reliability of the tool. Pay attention to common themes. If multiple reviews mention similar issues, this could indicate a potential problem. Yet, don’t overlook overly positive reviews; they may be biased.

Analyzing feedback on different platforms is essential. Sometimes, users may focus on specific features, leaving out critical information. For instance, a tool might excel in precision but lack durability. These details can affect your long-term satisfaction. Seek reviews that highlight both strengths and weaknesses. A balanced view supports better decision-making.