2025 Top 10 Industrial Automation Solutions Transforming Manufacturing Efficiency

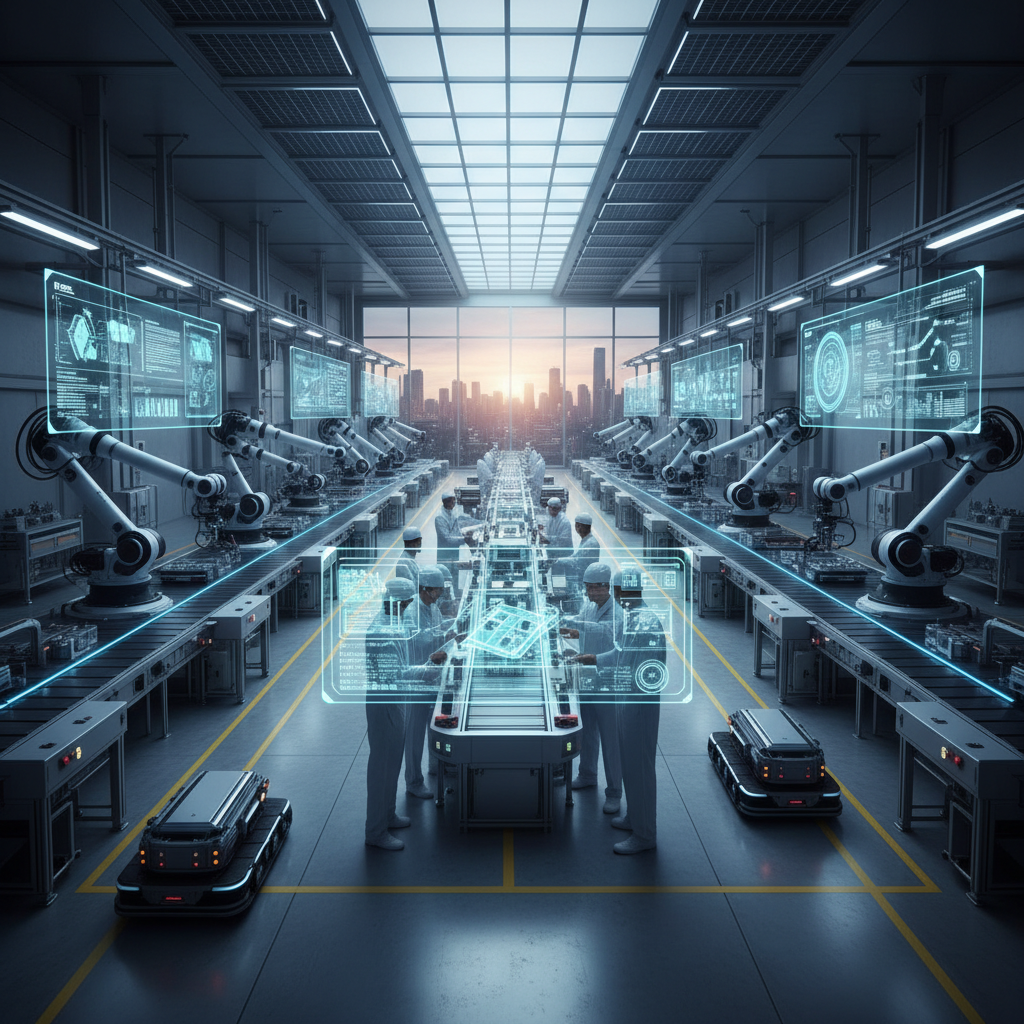

In the rapidly evolving landscape of manufacturing, the integration of industrial automation solutions has emerged as a key driver of operational efficiency and competitiveness. A recent report by Markets and Markets predicts that the global industrial automation market is expected to reach $296.70 billion by 2026, growing at a CAGR of 8.2% from 2021. This shift towards automation not only enhances production speed and accuracy but also significantly reduces labor costs and operational risks, paving the way for smarter factories.

Experts in the field continue to emphasize the transformative power of these technologies. According to Dr. Emily Chang, a renowned industrial automation solutions specialist, “The future of manufacturing lies in our ability to adapt and implement automation strategies that optimize performance while maintaining flexibility.” As industries increasingly adopt advanced robotics, artificial intelligence, and the Internet of Things (IoT), it becomes evident that the potential for improved manufacturing efficiency is vast.

As we explore the top 10 industrial automation solutions that are set to reshape the manufacturing sector by 2025, it is clear that these advancements will not only revolutionize productivity but also redefine the workforce landscape, making it imperative for companies to invest and adapt accordingly.

Emerging Technologies Driving Industrial Automation Innovations

As we approach 2025, the landscape of industrial automation is rapidly evolving, spurred by emerging technologies that are redefining manufacturing efficiency. Reports indicate that the global industrial automation market is projected to reach approximately $295 billion by 2026, growing at a CAGR of about 9.2% from 2021. This growth is driven by advancements in robotics, artificial intelligence, and IoT, which collectively enhance operational productivity and optimize supply chains.

One of the most significant innovations is the integration of AI-driven analytics, which enables real-time monitoring of machinery and predictive maintenance. According to a recent McKinsey report, companies utilizing advanced analytics experience a 20-25% increase in overall equipment effectiveness. Furthermore, collaborative robots, or cobots, are becoming increasingly popular on the factory floor, enhancing workforce capabilities without replacing jobs.

Tips: To maximize the benefits of these technologies, manufacturers should prioritize employee training on automation tools and foster a culture of continuous improvement. Additionally, investing in robust cybersecurity measures is essential to protect sensitive data and maintain operational integrity amidst increasing digitalization in manufacturing. Embracing these strategies can lead to significant gains in efficiency and competitiveness in an ever-evolving market.

Key Benefits of Implementing Automation Solutions in Manufacturing

The implementation of automation solutions in manufacturing is leading to significant enhancements in operational efficiency. One of the key benefits is the increased productivity achieved through streamlined processes.

Automated systems can operate continuously without the need for breaks, which not only maximizes output but also reduces cycle times. This relentless pace fosters a competitive edge in the market, allowing manufacturers to meet rising consumer demands swiftly.

Moreover, automation solutions contribute to improved quality control. By utilizing precise robotics and sophisticated software, manufacturers can minimize human error and ensure consistent product quality. Enhanced monitoring capabilities also allow for real-time data analysis, enabling quicker adjustments to production lines. This not only reduces waste but also enhances overall profitability. In the rapidly evolving landscape of manufacturing, these advancements position companies to thrive by embracing technological innovations that redefine their operational frameworks.

Case Studies of Successful Automation Transformations in Industry

The Industrial Internet of Things (IIoT) is a pivotal force behind the transformation of manufacturing efficiency. By leveraging connectivity and data analytics, IIoT has enabled manufacturers to optimize operations, reduce downtime, and enhance product quality. A comprehensive review of IIoT highlights its role in integrating advanced technologies into production processes, allowing for real-time monitoring and predictive maintenance. This technological evolution is essential as industries adapt to the demands of an increasingly digitized marketplace.

An important aspect of this transformation is the five-layer IIoT architectural framework, which delineates the evolution of smart manufacturing into distinct layers: device, connectivity, edge, data, and application. Each layer plays a critical role in creating a cohesive ecosystem that supports automation and intelligent decision-making. Furthermore, seven key technologies have been identified as accelerators of manufacturing transformation, each contributing uniquely to the efficiency and agility of manufacturing operations. By embracing these technologies, companies can navigate the complexities of digital transformation while unlocking new levels of productivity and innovation.

Future Trends in Industrial Automation for Enhanced Productivity

As we advance towards 2025, the industrial automation landscape is poised for transformative changes, driven by emerging technologies such as artificial intelligence, IoT, and robotics. The global market for IoT in manufacturing is projected to significantly expand from an estimated $116.52 billion in 2024 to $141.18 billion by 2025, ultimately reaching $673.95 billion by 2032. This growth signifies a vital shift in how industries approach manufacturing efficiency, with automation technologies enhancing production capabilities and operational workflows.

The focus on autonomous and intelligent manufacturing systems, particularly through advancements in PLC (Programmable Logic Controllers) and robotics, reflects a broader trend towards smart facilities, or "lighthouse factories". These establishments, characterized by their integration of digital and IoT technologies, are indicators of the industry's commitment to not just maintaining but boosting productivity. As stakeholders invest in automation solutions, the industrial sector prepares for a more integrated and performance-oriented future, redefining manufacturing efficiency across various domains.

2025 Top 10 Industrial Automation Solutions Transforming Manufacturing Efficiency

| Solution Name |

Key Features |

Impact on Efficiency (%) |

Expected Adoption Year |

| AI-driven Process Optimization |

Machine Learning, Predictive Analytics |

25 |

2025 |

| Robotic Process Automation |

Task Automation, Improved Precision |

30 |

2024 |

| IoT Integration |

Real-Time Monitoring, Predictive Maintenance |

20 |

2025 |

| Smart Manufacturing Systems |

Data Analytics, AI |

35 |

2025 |

| Digital Twins |

Virtual Simulation, Performance Analysis |

28 |

2024 |

| Collaborative Robots (Cobots) |

Safe Human-Robot Interaction, Flexible Automation |

22 |

2025 |

| Supply Chain Automation |

Streamlined Logistics, Inventory Management |

40 |

2025 |

| Edge Computing |

Real-Time Data Processing, Reduced Latency |

18 |

2024 |

| Augmented Reality for Training |

Immersive Learning, Enhanced Safety |

24 |

2025 |

| Blockchain for Supply Chain |

Transparency, Security, Traceability |

15 |

2025 |

Challenges and Solutions in Adopting New Automation Technologies

The rapid evolution of automation technologies presents both challenges and opportunities for manufacturers. A recent report by McKinsey & Company highlights that nearly 75% of companies in the manufacturing sector face significant obstacles in integrating new automation solutions. These barriers often include high implementation costs, resistance to change among the workforce, and gaps in necessary skills. As organizations strive to enhance operational efficiency, addressing these issues becomes crucial for successful technology adoption.

Furthermore, a study from Deloitte indicates that investment in industrial automation is expected to grow by 20% annually over the next five years. However, many companies underestimate the importance of employee training and change management in this process. By equipping their staff with the required skill sets and fostering an open culture towards automation, manufacturers can mitigate the workforce's apprehension towards new technologies.

Companies that prioritize these solutions not only improve their chances of successful implementation but also stand to gain a competitive edge in an increasingly automated future.