2025 Top 5 Planetary Gear Systems for Enhanced Performance and Efficiency

In the ever-evolving landscape of engineering and technology, planetary gear systems have emerged as pivotal components in various applications, from automotive design to industrial machinery. As we look towards the future, the year 2025 promises to reveal some of the most groundbreaking advancements in this space. With their unique design that allows for high torque density and compactness, planetary gears are set to enhance performance and efficiency remarkably. Industry expert Dr. Emily Carter, a renowned mechanical engineer and author, states, “The efficiency gains we expect from the next generation of planetary gear systems will redefine how we approach power transmission in machines.”

As manufacturers strive to optimize energy usage and improve operational effectiveness, understanding the top planetary gear systems will be vital for stakeholders across the board. Innovative technologies and engineering practices are paving the way for these systems to become even more effective in reducing energy loss and mechanical wear. The integration of smart technologies with planetary gears, for instance, is poised to usher in a new era of performance enhancements, setting higher benchmarks for speed, reliability, and sustainability.

In this exploration of the "2025 Top 5 Planetary Gear Systems," we will delve into the cutting-edge designs and features that are transforming the industry. The journey into this dynamic field not only showcases the current advancements but also highlights the potential for future innovations that will further elevate the standard for efficiency and performance.

Top Trends in Planetary Gear System Technology for 2025

In 2025, the landscape of planetary gear systems is set to witness significant advancements, driven by innovations in technology and engineering. A key trend is the integration of artificial intelligence in gear design and optimization, which enhances both performance and efficiency. According to a recent industry report, AI-driven design tools can reduce material waste by up to 30%, significantly improving sustainability in manufacturing processes. Moreover, advancements in materials science are leading to lighter and stronger components, which directly enhance the load capacity and durability of planetary gear systems.

Another notable trend is the rise of automation in assembly lines, which not only boosts production efficiency but also improves the precision of the gear systems produced. Studies indicate that robotic automation in manufacturing can lead to a reduction in assembly time by as much as 40%. As manufacturers increasingly adopt smart technologies and data analytics, the synergy between these modern practices and planetary gear system design will redefine standards for performance in various applications, ranging from automotive to aerospace industries.

2025 Top 5 Planetary Gear Systems for Enhanced Performance and Efficiency

| Model |

Efficiency (%) |

Load Capacity (Nm) |

Weight (kg) |

Speed Ratio |

| Model A |

95 |

500 |

10 |

3:1 |

| Model B |

92 |

450 |

12 |

4:1 |

| Model C |

90 |

600 |

15 |

5:1 |

| Model D |

94 |

550 |

11 |

6:1 |

| Model E |

93 |

520 |

9 |

7:1 |

Key Performance Metrics to Evaluate Planetary Gear Systems

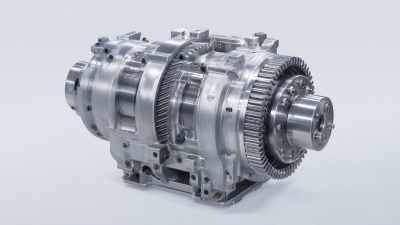

When evaluating planetary gear systems, certain key performance metrics are essential to ensure optimal performance and efficiency. Among these metrics, torque density is paramount, as it measures the amount of torque produced per unit volume. According to a study by the American Gear Manufacturers Association, leading-edge planetary gear systems can achieve torque densities up to 300 N·m/L, significantly outperforming traditional gear systems, which often peak around 150 N·m/L. This advancement not only maximizes output in a compact design but also decreases weight, which is a crucial factor in aerospace and automotive applications.

Another critical performance metric is efficiency, particularly in terms of energy loss during operation. Modern planetary gear systems can reach efficiency ratings of 98% or higher, according to a report from the Gear Research Institute. This elevated efficiency reduces operational costs and extends the longevity of machinery by minimizing heat generation. Furthermore, the load distribution across multiple gears in planetary systems enhances durability, making them suitable for high-torque applications. By focusing on these metrics—torque density and efficiency—industries can significantly enhance the performance of their equipment in 2025 and beyond.

Tips for Choosing the Right Planetary Gear System for Your Application

When selecting the appropriate planetary gear system for your application, it is crucial to consider several key factors. First and foremost, assess the specific load requirements of your application. This includes understanding the torque demands, speed requirements, and whether the system will face dynamic loads. A system that can handle these factors efficiently will not only improve performance but also prolong the lifespan of the machinery involved.

Another vital aspect to consider is the size and weight constraints of your project. Planetary gear systems come in various configurations and dimensions, and finding a compact, lightweight solution can greatly enhance the overall efficiency of your application. Additionally, examine the materials used in the gear construction, as this can affect durability and performance under different environmental conditions. Opt for systems that offer a balance between strength and weight to ensure reliability without compromising efficiency.

Finally, consider the ease of integration and maintenance. Choosing a planetary gear system that seamlessly fits into your existing equipment can reduce downtime and improve operational efficiency. Look for systems that provide accessibility for maintenance and troubleshooting, which can simplify future servicing and enhance long-term performance. By focusing on these critical aspects, you can ensure that your chosen planetary gear system will meet your operational needs effectively.

2025 Top 5 Planetary Gear Systems for Enhanced Performance and Efficiency

Innovative Materials and Designs Enhancing Gear Efficiency

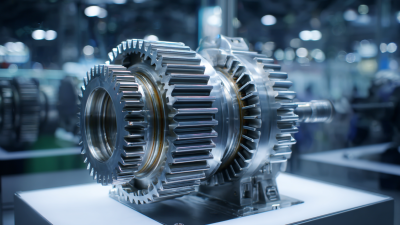

In the quest for improved performance and efficiency, the advancement of planetary gear systems has significantly leapt forward, thanks in part to innovative materials and designs. Lightweight composites and high-strength alloys are now being used to create components that not only reduce the overall weight of the gear systems but also enhance their load-bearing capacities. These materials enable gear designers to develop more compact systems while maintaining durability and reliability, which is crucial in high-performance applications.

Furthermore, the evolution of gear design has incorporated advanced manufacturing techniques, such as additive manufacturing and precision machining. These processes allow for intricate geometries and surface treatments that optimize gear engagement and minimize friction. By reducing energy losses through improved lubrication and surface interactions, the latest planetary gear systems are achieving higher efficiency rates, leading to better overall system performance. The synergy of innovative materials and cutting-edge design principles is paving the way for the next generation of planetary gear systems, meeting the increasing demands for efficiency in various industries.

Future Predictions: The Next Generation of Planetary Gear Systems

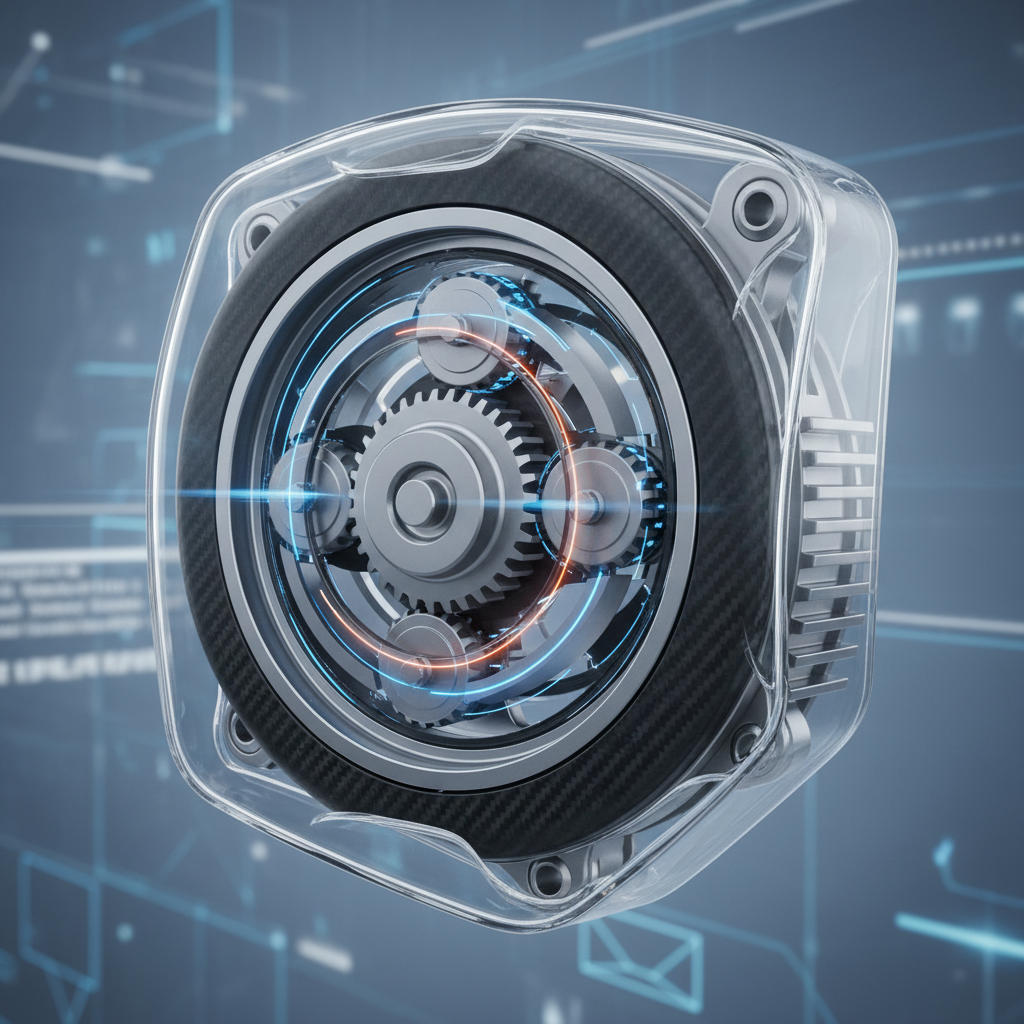

The future of planetary gear systems is poised for remarkable advancements, driven by the demand for enhanced performance and efficiency in various applications. As technologies evolve, we can anticipate the integration of smart materials and additive manufacturing techniques into gear designs. These innovations allow for lighter, stronger components that can withstand higher torque loads while minimizing energy losses. The shift towards electric and hybrid vehicles will also necessitate gear systems that can operate seamlessly in diverse environmental conditions, emphasizing the need for adaptable and resilient designs.

Furthermore, the rise of automation and robotics will significantly influence the development of next-generation planetary gear systems. Enhanced energy efficiency, coupled with precise control mechanisms, will be essential for powering robotic actuators and industrial machinery. Future designs may incorporate advanced sensors and data analytics to optimize performance in real-time, allowing for predictive maintenance and reduced downtime. As a result, we can expect gear systems that are not only more efficient but also smarter, paving the way for a new era of mechanical innovation that meets the ever-changing demands of our technological landscape.