Top 10 Drive Technologies Transforming the Future of Automation?

The integration of drive technologies is revolutionizing automation across various industries. According to a recent report by MarketsandMarkets, the global drive technologies market is expected to reach USD 200 billion by 2027, growing at a CAGR of 5.6%. This surge signifies a pivotal moment in manufacturing and process automation.

As John Smith, an expert in automation systems, notes, “Drive technologies will redefine efficiency in operations.” This embodies the essence of modern engineering. Advanced drive systems are enhancing performance while reducing energy consumption, a crucial factor in today’s sustainability efforts. These technologies are not without challenges; implementing them requires significant investments and skilled personnel.

The evolution of drive technologies indicates a shift towards smarter, more efficient systems. Yet, companies must address integration obstacles. They should consider the implications of rapid technological advancement. Industry players must adapt or risk falling behind as they navigate this complex landscape. The future of automation hinges on how well organizations embrace these drive technologies.

The Role of Artificial Intelligence in Automation Drive Technologies

Artificial intelligence is reshaping automation drive technologies. Recent reports show that AI can boost efficiency by up to 30%. Companies are leveraging AI to optimize operational workflows. This real-time data processing allows for quicker decision-making. Predictive maintenance is a prime example, reducing unexpected downtimes significantly.

However, the integration of AI is not without challenges. Many organizations struggle with data quality. Poor data leads to inaccurate predictions. About 40% of businesses reported issues in translating AI insights into actions. Furthermore, workforce readiness is a concern. Employees need training to work alongside AI systems effectively. A lack of skills can hinder the adoption of these technologies.

Despite these issues, the benefits are undeniable. AI-driven automation can drive productivity to unprecedented levels. As sectors like manufacturing and logistics adopt these innovations, a transformation in efficiency is imminent. Continuous evaluation of AI systems and employee readiness is crucial for harnessing these advancements. As organizations navigate this landscape, a balanced approach will be essential.

Top 10 Drive Technologies Transforming the Future of Automation

Advancements in Robotics: Redefining Precision and Efficiency in Industries

Advancements in robotics are revolutionizing industries by enhancing precision and efficiency. A recent report from the International Federation of Robotics shows that the global market for industrial robots is expected to reach $70 billion by 2025. This surge in demand is driven by automation. Manufacturers are now seeking solutions to reduce errors and increase productivity.

Robots equipped with advanced algorithms can perform complex tasks with incredible accuracy. They significantly lower the margin for human error. In sectors like automotive and electronics, robots can operate at speeds up to 300 parts per minute. However, as automation increases, the workforce faces challenges in adapting to new technology. Many workers find it difficult to learn new skills.

Moreover, the rise of collaborative robots, or cobots, presents mixed outcomes. On one hand, they enhance productivity while working alongside humans. On the other hand, there are concerns about job displacement. A study by McKinsey highlights that up to 30% of jobs could be automated by 2030. This forces industries to rethink workforce training and development strategies. Balancing efficiency with workforce dynamics is a critical reflection point.

Impact of IoT Integration on Drive Systems in Smart Manufacturing

The integration of IoT in drive systems is redefining smart manufacturing. Machines can now communicate in real-time, sharing data to optimize operations. This connectivity leads to enhanced efficiency and reduced downtime. Sensors embedded in drive systems track performance metrics and send alerts when maintenance is needed. Manufacturers can respond quickly to potential issues.

However, this transformation is not without challenges. Dependency on technology raises concerns about cybersecurity. A breach could halt operations and compromise sensitive data. There is also the issue of compatibility between old and new systems. Legacy equipment may struggle to integrate smoothly with modern IoT solutions.

Adapting to this new landscape requires ongoing education and investment. Employees need training to manage sophisticated technologies. Manufacturers must also consider the cost of updating infrastructure. Finding a balance between innovation and practicality is essential. Embracing the potential of IoT while acknowledging its hurdles can lead to groundbreaking advancements in automation.

Electric Drive Technologies: Shaping Sustainable Automation Solutions

Electric drive technologies are at the forefront of revolutionizing automation.

These innovations enable efficient control of machinery, reducing energy consumption. As industries push for sustainability, electric drives play a critical role. They allow manufacturers to optimize processes while minimizing environmental impact.

Integration of renewable energy sources is transforming automation landscapes. Many systems are now designed to work seamlessly with solar and wind energy. However, this shift isn't without challenges. Fluctuations in energy availability can disrupt operations. Balancing efficiency with reliability requires constant evaluation.

Moreover, advancements in battery technology are reshaping electric drives. Energy storage solutions are improving, yet they still face limitations. Current batteries often struggle with longevity and charging speed. Continuous innovation is necessary to overcome these hurdles. A future where electric drive technologies fully support sustainable automation is possible but demands our commitment.

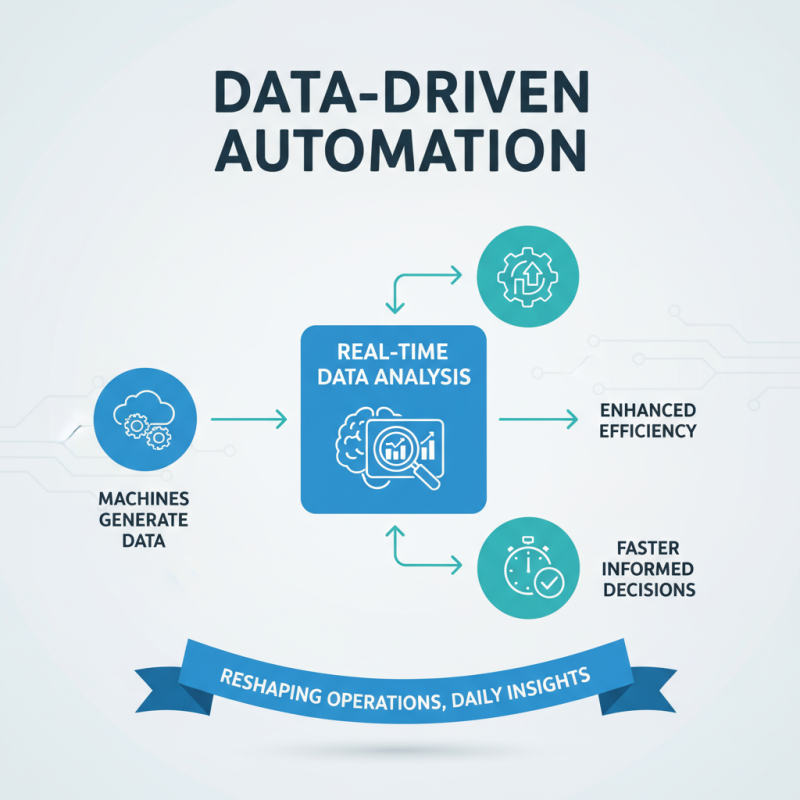

Future Trends: Data-Driven Decision-Making in Automated Processes

Data-driven decision-making is reshaping automation. Every day, machines generate vast amounts of data. This data holds insights that can enhance operational efficiency. Businesses can now analyze real-time data to make informed decisions faster than ever before.

Automation processes benefit greatly from this approach. For example, consider manufacturing. Sensors on machines monitor conditions like temperature and pressure. Data collected helps identify potential failures before they occur. However, relying solely on data can be misleading. It's important to remember that data must be contextualized. Numbers without context can lead to poor choices.

Looking ahead, the challenge is to ensure data quality. As automation expands, so does the data complexity. Flawed data can result in significant setbacks. Moreover, there is a risk of over-reliance on technology, potentially stifling human insight. Balancing data analysis with human intuition remains crucial in this rapidly evolving landscape. Adapting to new technologies while reflecting on their limitations is a continuous journey for organizations.