Top 10 Precision Gearing Solutions You Need to Know?

In the rapidly evolving landscape of technology, precision gearing has emerged as a critical component across various industries. According to a recent report by MarketsandMarkets, the global precision gearing market is projected to reach $10 billion by 2025, growing at a CAGR of 6% from 2020. This growth reflects the increasing demand for high-performance machinery in sectors like robotics, aerospace, and automotive.

Expert Dr. Emily Carter, a leading figure in precision engineering, emphasizes, "Precision gearing solutions drive efficiency and accuracy in modern applications." As industries strive for automation, the significance of reliable gearing systems cannot be overstated. Each gear's role is not just in motion but in ensuring that every operation meets stringent precision standards.

However, the complexity of selecting the right precision gearing solution can be daunting. Many companies face challenges in aligning their specific needs with available technologies. With the market expanding, there is a crucial need to stay informed about the top precision gearing solutions available today. Understanding these options can help mitigate risks and enhance overall performance.

Top Trends in Precision Gearing Solutions for 2023

Precision gearing solutions are evolving rapidly in 2023. These advancements focus on efficiency and adaptability. As industries push for smarter machinery, gearing systems must keep pace. Users demand improved performance without compromising quality. The trend emphasizes integrating advanced materials and lightweight components. This shift enhances product durability and reduces energy consumption.

Another notable development is the rise of customizable solutions. Industries need gearing that fits unique specifications. Standard solutions often fall short. Custom designs provide flexibility, allowing for tailored applications. This trend promotes innovation but can lead to complexities in production. Manufacturers face challenges in balancing custom orders with standard offerings.

Data-driven designs are also gaining traction. Utilizing AI and simulation tools, engineers can optimize gear performance. This approach allows for predictive maintenance, prolonging equipment lifespan. However, it raises questions about the reliance on technology. Over-dependence can make systems vulnerable to unexpected failures. Striking a balance between innovation and traditional methods is essential for future advancements.

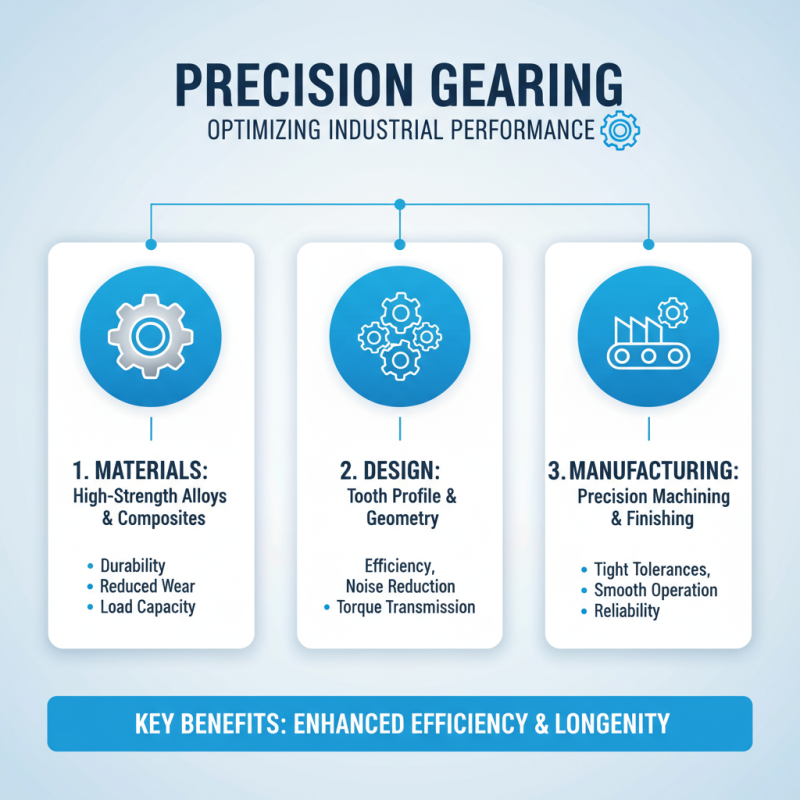

Innovations in Material Science for Enhanced Gearing Solutions

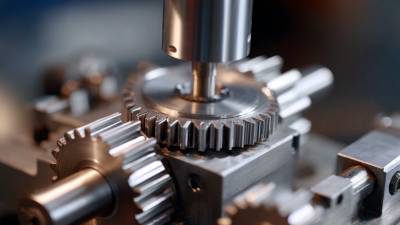

Material science is revolutionizing the precision gearing sector. Recent studies suggest that advanced materials can enhance strength and reduce weight in gearing systems by up to 30%. For example, carbon fiber composites are showing great promise. They offer high durability while minimizing the risk of gear failure.

Understanding the properties of new materials is crucial. They not only improve efficiency but also extend the lifespan of gears. Research indicates that gears made with bionic structures demonstrate increased load capacity. This is an exciting development for industries requiring high precision and reliability.

**Tips:** Always analyze the scope of material applications in your designs. Conducting regular tests on gear performance can reveal weaknesses early. Remember, sometimes, high-performance materials do not guarantee high efficiency. It's essential to assess compatibility with existing systems.

Top 10 Precision Gearing Solutions

The chart below illustrates the top 10 precision gearing solutions based on their material innovation and performance metrics. The data highlights various types of gearing solutions along with their respective efficiency ratings.

Application Areas Driving Demand for Precision Gearing Solutions

Precision gearing solutions are crucial in various industries. Manufacturing, automotive, and aerospace are among the key application areas. These sectors rely heavily on precision gears for efficient operation.

In manufacturing, precision gears improve machine performance. They ensure high accuracy and reliability in processes. In automotive applications, they support enhanced vehicle dynamics and fuel efficiency. Aerospace applications demand extreme precision for safety and reliability.

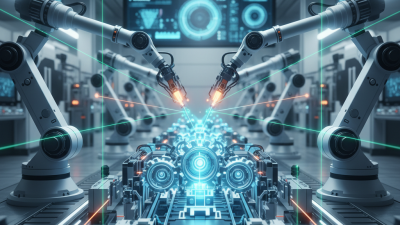

The growing demand for automation also drives the need for precision gearing solutions. Robotics and conveyor systems require accurate gear systems. However, challenges exist. Precision gear manufacturing can be costly. Quality control is essential but often overlooked. Companies must reflect on continually improving their processes. Embracing new technologies and methods can enhance efficiency and performance.

Market Analysis: Growth Projections for Precision Gearing Industry

The precision gearing industry is experiencing noteworthy growth. Experts project significant advancements in various sectors, particularly automation and robotics. These areas demand higher efficiency and accuracy, creating a surge in the need for precision gears. As technology evolves, innovations drive the market forward, aligning with the increasing complexity of machinery.

However, challenges persist. Supply chain issues can disrupt production schedules. Companies must be agile to adapt to those changes. Additionally, the rising cost of raw materials could affect pricing strategies. Firms need to reassess their sourcing approaches to maintain competitiveness in the sector.

As the market expands, collaboration may become essential. Businesses could benefit from partnerships to share resources and knowledge. Investing in new technologies will also be crucial. The ability to produce custom gearing solutions can differentiate a company in a crowded marketplace. The future looks promising, but a reflective and adaptive mindset is vital for success.

Top 10 Precision Gearing Solutions - Market Analysis: Growth Projections for Precision Gearing Industry

| Rank |

Solution Type |

Market Share (%) |

Growth Rate (CAGR) |

Key Applications |

| 1 |

Spur Gears |

25.4 |

5.6% |

Industrial Machinery |

| 2 |

Planetary Gears |

21.3 |

6.2% |

Automotive, Robotics |

| 3 |

Bevel Gears |

18.1 |

4.9% |

Aerospace, Aviation |

| 4 |

Worm Gears |

10.7 |

3.8% |

Lift Mechanisms |

| 5 |

Helical Gears |

9.5 |

5.1% |

Marine Applications |

| 6 |

Rack and Pinion |

7.8 |

4.3% |

Automated Systems |

| 7 |

Hypoid Gears |

5.6 |

3.5% |

Heavy Machinery |

| 8 |

Crown Gears |

4.4 |

2.9% |

Transfer Cases |

| 9 |

Differential Gears |

3.9 |

3.7% |

Automobiles |

| 10 |

Variable Gears |

2.3 |

4.0% |

Gearing Systems |