Top 2025 Worm Drive Applications and Innovations You Need to Know

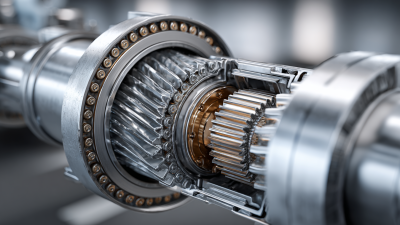

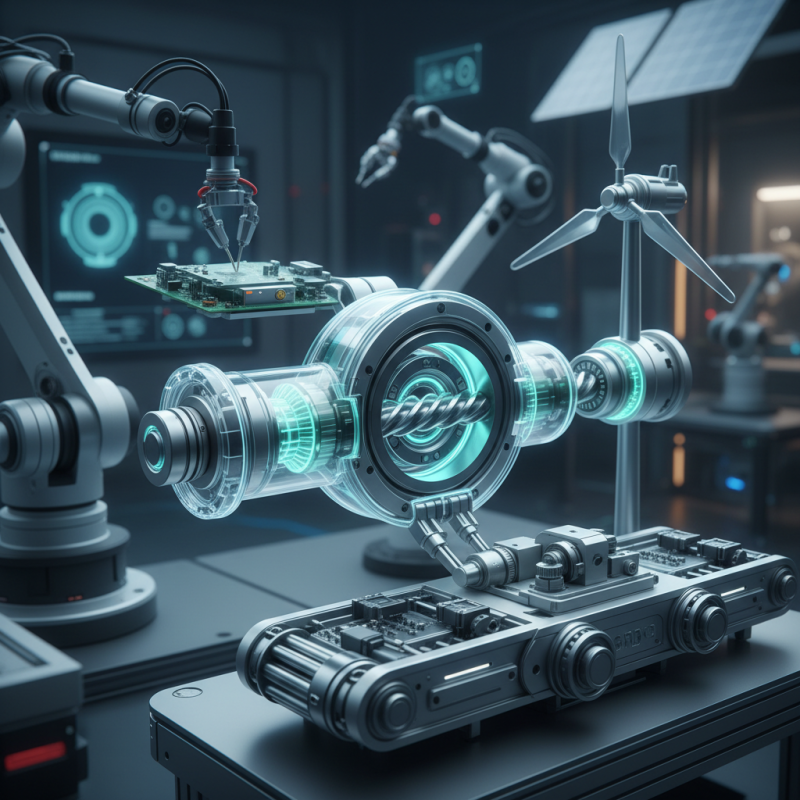

Worm drives are a critical component in various mechanical applications, known for their ability to provide high torque and compact design. As we look ahead to 2025, the evolution of worm drive technology is set to open new avenues across industries such as automation, robotics, and renewable energy. Innovations in materials, precision engineering, and digital integration promise to enhance the efficiency and reliability of worm drive systems, making them indispensable in modern machinery.

This article delves into the top worm drive applications anticipated for 2025, highlighting the transformative innovations that are shaping their future. From advanced motion control systems to energy-efficient designs, the developments in worm drive technology are expected to revolutionize how machines operate. By understanding these emerging trends, engineers and industry leaders can take advantage of the benefits that worm drives will continue to offer in various applications, improving performance and reducing costs.

Top Trends in Worm Drive Technology for 2025

As we move towards 2025, the landscape of worm drive technology is expected to witness remarkable advancements, particularly in efficiency and miniaturization. One of the most significant trends is the integration of smart sensors into worm drive systems, allowing for real-time monitoring and diagnostics. These sensors can provide valuable feedback on performance and wear and tear, enabling predictive maintenance and reducing downtime. Furthermore, the incorporation of IoT (Internet of Things) capabilities will facilitate remote management, making it easier for operators to control systems from anywhere, enhancing operational efficiency.

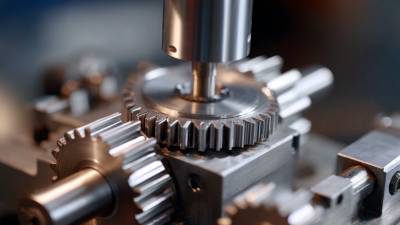

Another key trend in worm drive technology is the focus on sustainability and energy efficiency. Manufacturers are working on developing lightweight materials and innovative designs that minimize energy loss during operation. This not only reduces operational costs but also aligns with global efforts to reduce carbon footprints. Additionally, advancements in manufacturing techniques, such as additive manufacturing, are paving the way for more complex and optimized gear designs, leading to improved performance and longevity of worm drives.

These innovations are transforming the capabilities of worm drive systems, making them more adaptable for various applications in industries ranging from robotics to renewable energy.

Key Industries Benefiting from Worm Drives: A Data-Driven Analysis

Worm drives have emerged as a critical component across various industries, thanks to their unique design and operational efficiency. One key sector benefiting from these drives is the manufacturing industry, where they play a vital role in conveyor systems and automated machinery. The ability of worm drives to provide high torque at low speeds makes them ideal for heavy-duty applications, enabling precise control in assembly lines and production processes. Data indicates that their use can significantly reduce energy consumption, making them an attractive option for manufacturers focused on sustainability.

Another significant area where worm drives are making waves is in the automotive sector. As vehicles become more sophisticated with the integration of advanced technologies, the demand for reliable transmission systems has increased. Worm drives offer compact solutions that enhance performance while minimizing space constraints. Their ability to provide excellent gear reduction and smooth operation makes them valuable for electric vehicles, where efficiency and precision are paramount. This trend suggests a growing reliance on worm drives as the automotive industry continues to evolve, particularly with the shift towards electric and autonomous vehicles.

Top 2025 Worm Drive Applications and Innovations

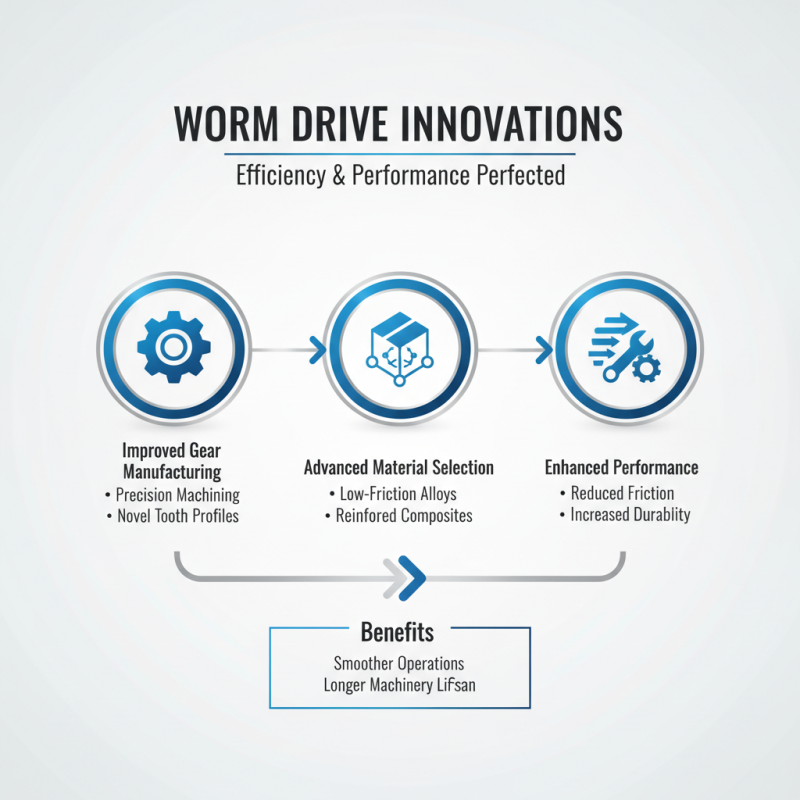

Innovations in Worm Drive Design: Enhancing Efficiency and Performance

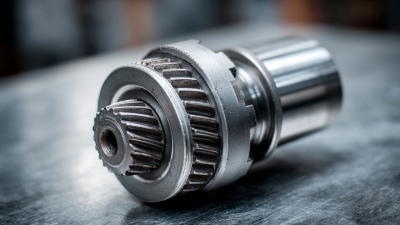

Innovations in worm drive design have made significant strides in recent years, enhancing both efficiency and performance across various applications. These advanced designs often incorporate improved gear manufacturing techniques and meticulous material selection, leading to reduced friction and increased durability. As industries look to optimize their mechanical systems, the adoption of these innovative worm drives can result in smoother operations and a longer lifespan for essential machinery.

Tips for implementing new worm drive technology include conducting thorough feasibility studies to better understand operational needs. Assess your specific application requirements, such as load capacity and environmental conditions, to select the most suitable worm drive design. Additionally, investing in high-quality lubrication systems can further enhance performance by minimizing wear and tear on gear components.

Furthermore, consider the potential for integrating smart technology into worm drive systems. The use of sensors and predictive maintenance tools can aid in monitoring performance metrics, leading to timely interventions and minimizing downtime. By staying updated on the latest advancements in worm drive innovations, industries can significantly improve operational efficiency and overall productivity.

Sustainability in Worm Drive Applications: Eco-Friendly Solutions

The importance of sustainability in worm drive applications is increasingly being recognized across various industries. As businesses strive to reduce their carbon footprints, innovations in worm drive technology are paving the way for more eco-friendly solutions. Recent industry reports indicate that integrating advanced materials and energy-efficient designs can lead to a significant reduction in energy consumption, with some estimates suggesting improvements of up to 30% in efficiency compared to traditional systems.

Another exciting trend is the adoption of recyclable materials in the manufacturing of worm drives. This shift not only lessens the environmental impact but also aligns with global sustainability goals. According to a 2023 sustainability report by a leading engineering organization, over 40% of manufacturers are now prioritizing eco-friendly materials in their designs, vastly contributing to the sustainable lifecycle of their products. These advancements ensure that worm drives not only meet performance standards but also contribute to reducing environmental harm.

Tips: When selecting worm drive solutions, consider options with high energy efficiency ratings and look for products that feature recyclable components. Additionally, stay updated on industry trends to ensure that your applications are aligned with the latest eco-friendly innovations. Engaging with suppliers who prioritize sustainability can also provide additional insights into responsible practices within the worm drive market.

Top 2025 Worm Drive Applications and Innovations You Need to Know - Sustainability in Worm Drive Applications: Eco-Friendly Solutions

| Application Area |

Description |

Innovative Features |

Eco-Friendly Practices |

| Renewable Energy Systems |

Used in wind turbines and solar trackers |

High efficiency and low noise operation |

Utilizes recyclable materials |

| Waste Management |

Used in conveyor systems for waste sorting |

Durability and optimized torque transfer |

Enhances recycling processes |

| Automotive Applications |

Used in electric vehicle drive systems |

Compact design and lightweight |

Improves battery life and efficiency |

| Robotics |

Integrated in precision machinery |

Offers high precision movement |

Minimizes energy consumption |

| Agricultural Equipment |

Utilized in automated planting and harvesting machines |

Robust construction for field use |

Reduces chemical usage with precision farming |

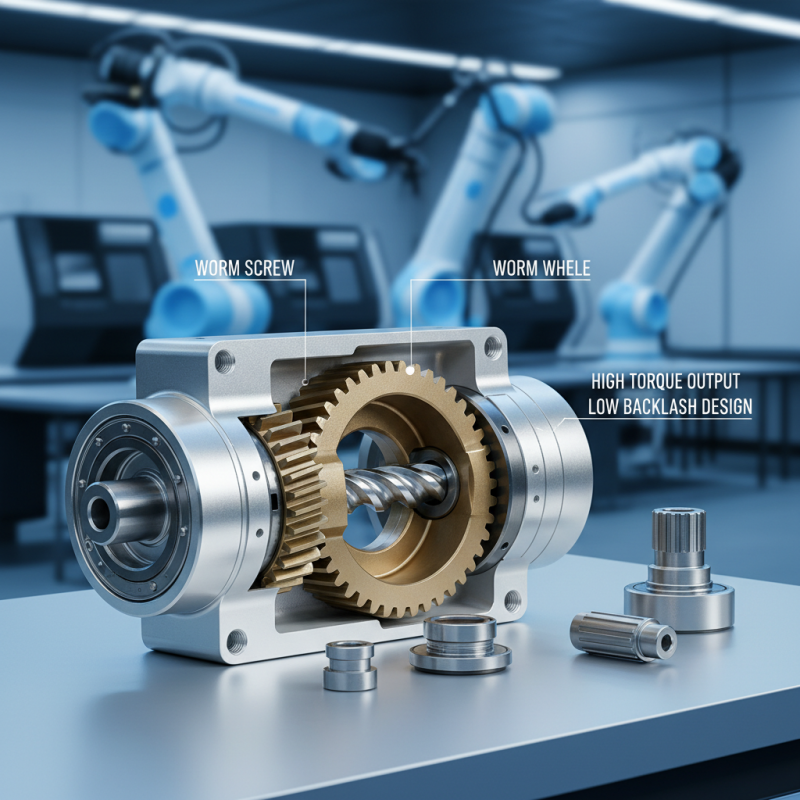

Future Market Projections for Worm Drive Systems by 2025

As the demand for efficient and reliable mechanical systems continues to grow across various industries, the worm drive systems market is projected to experience significant expansion by 2025. The increasing emphasis on automation and precision engineering has led to a surge in applications utilizing worm drive technology. Industries such as manufacturing, automotive, and robotics are increasingly adopting this technology due to its ability to provide high torque, compact design, and low backlash. This trend indicates a robust market trajectory fueled by ongoing innovations and enhancements in worm drive systems.

Future market projections suggest that advancements in materials and design will further enhance the capability and longevity of worm drive systems. Innovations like the integration of composite materials, improved lubrication techniques, and advanced manufacturing processes are expected to drive efficiencies and reduce overall operational costs. Moreover, the growing trend toward sustainability in engineering practices may prompt the development of greener worm drive solutions, positioning manufacturers favorably within the eco-conscious market landscape. As such, stakeholders in the industry should align their strategies to capitalize on these emerging opportunities and enhance their competitive edge by 2025.