Trustworthy Quality in Global Trade of Best Integrated Stepper Motors Made in China

As global trade continues to evolve, the demand for high-quality components, particularly Integrated Stepper Motors, has surged significantly. According to a recent industry report by MarketsandMarkets, the global stepper motor market is projected to reach USD 5.4 billion by 2025, growing at a CAGR of 6.4%. This growth is influenced by the increasing application of integrated stepper motors in sectors such as robotics, automation, and medical devices. China, as a leading manufacturer of stepper motors, plays a crucial role in this market, contributing to both innovation and affordability. However, the emphasis on trustworthiness and quality assurance remains paramount, as manufacturers strive to meet international standards and client expectations. This article delves into the factors that underpin the reliability of integrated stepper motors produced in China and highlights the advancements shaping their global trade landscape.

Understanding Integrated Stepper Motors: A Comprehensive Guide

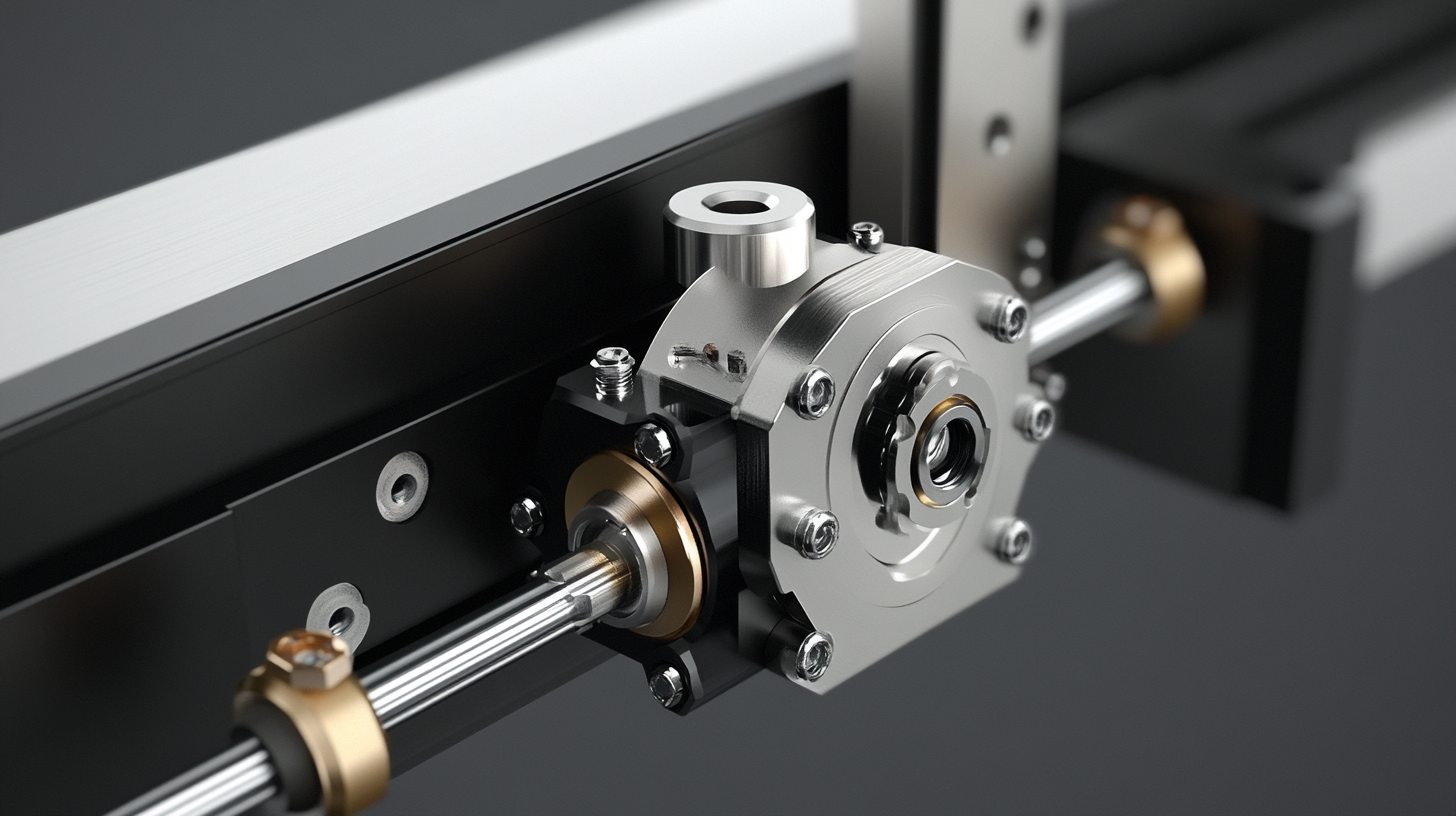

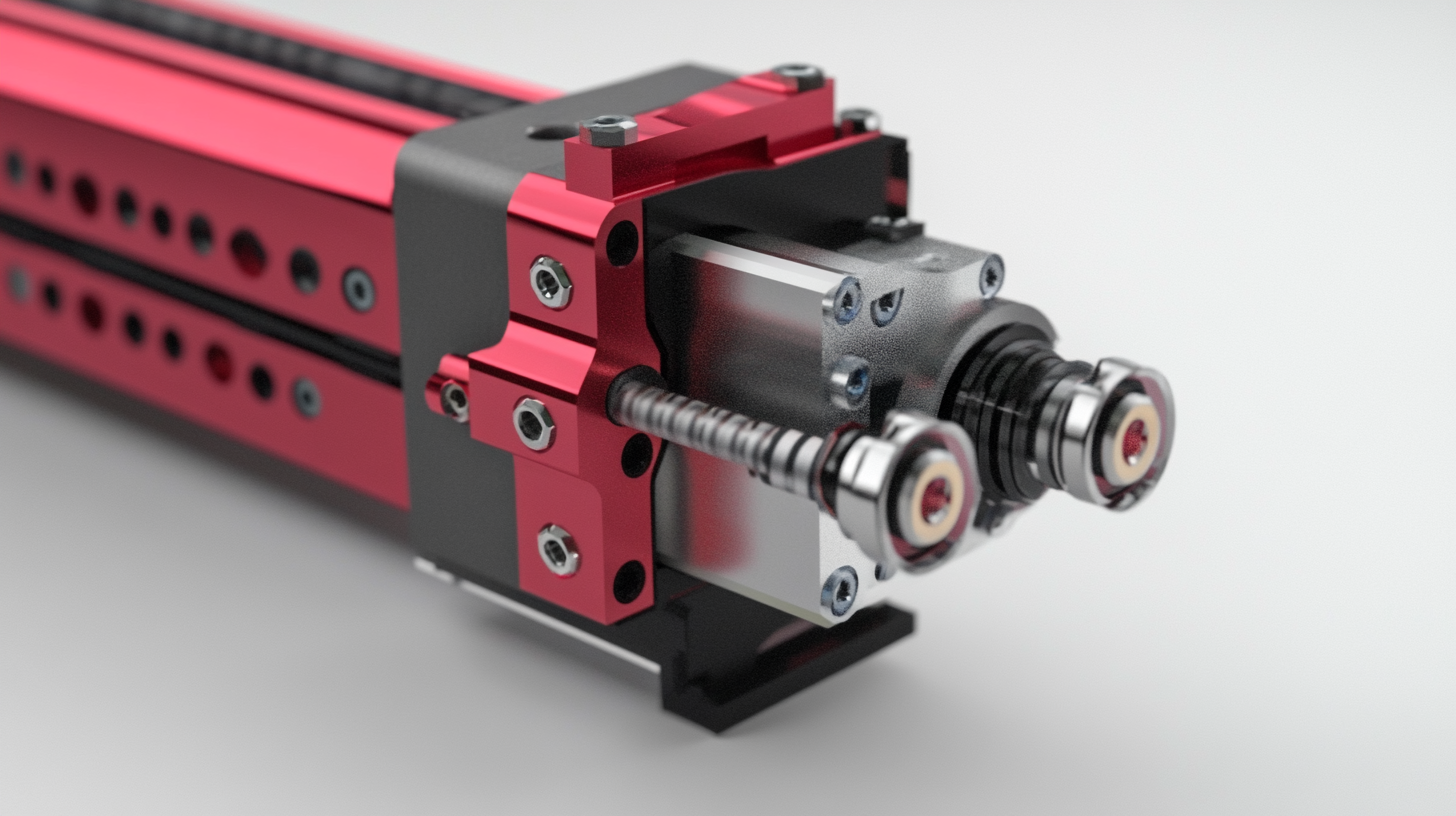

Integrated stepper motors have become a pivotal component in various applications, from robotics to CNC machines, due to their precision and reliability. Unlike traditional stepper motors, integrated stepper motors combine the motor and driver into a single compact unit, simplifying installation and reducing the overall footprint. This design not only saves space but also minimizes wiring complexities, making them ideal for modern automation systems. Their ability to deliver accurate positioning and consistent torque makes them preferred choices for engineers seeking efficiency in their technological solutions.

When exploring the market for integrated stepper motors, it’s crucial to understand the specifications that set the best models apart. Consider factors such as resolution, torque ratings, and power requirements, as these attributes directly influence performance in demanding environments. Moreover, the reliability of components is essential, especially for businesses relying on continuous operation. Purchasing from trustworthy manufacturers in China ensures that you're investing in high-quality motors that meet international standards, promoting longevity and performance in your applications.

By comprehensively understanding the features and capabilities of integrated stepper motors, you can make informed decisions that enhance productivity and innovation in your projects.

Key Features of High-Quality Stepper Motors in Global Trade

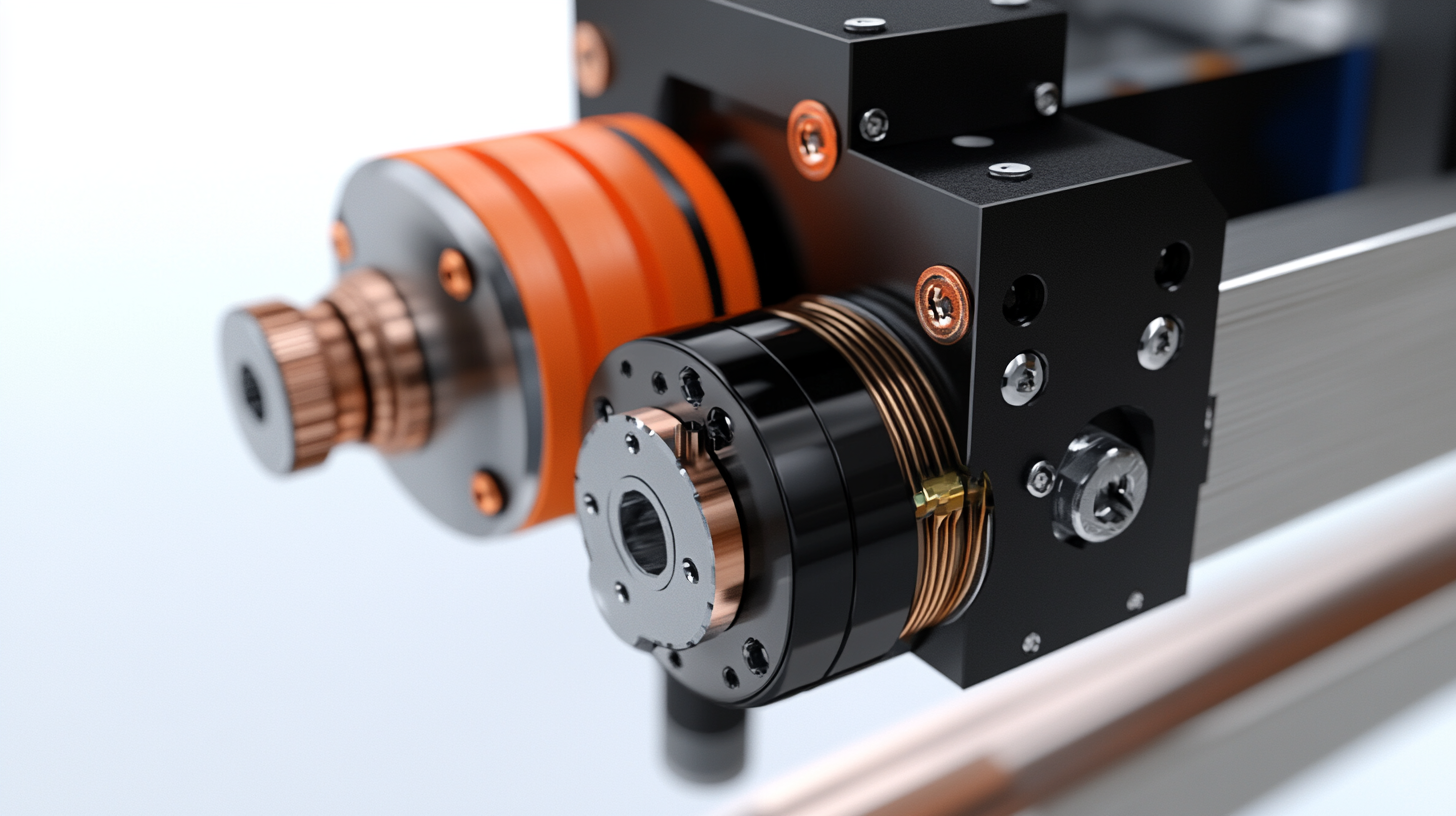

In the realm of global trade, the demand for high-quality integrated stepper motors made in China is on the rise, driven by their essential role in various industrial applications. These motors are recognized for their precision and reliability, making them crucial components in automation and control systems. Key features that distinguish high-quality stepper motors include superior torque performance, excellent positional accuracy, and robust thermal management. Moreover, advancements in manufacturing processes and technology have enabled Chinese manufacturers to produce motors that not only meet but exceed international standards, ensuring their competitiveness in the global market.

As the electric vehicle (EV) industry continues to grow, the need for reliable stepper motors has become even more pronounced. Electric vehicles demand high-performance components that can handle varying operational conditions, and stepper motors have proven their worth by providing smooth and efficient performance. With China rapidly advancing in innovation and technology, the quality and integration of these motors within the supply chain are continuously being refined. This evolution is pivotal for businesses seeking to enhance their operational efficiency while navigating the challenges presented by a dynamic global trade environment.

Trustworthy Quality in Global Trade of Best Integrated Stepper Motors Made in China

| Key Features | Description | Importance in Global Trade |

|---|---|---|

| Precision | High positional accuracy with minimal error margin. | Essential for applications requiring accuracy, enhancing product trustworthiness. |

| Durability | Designed for long operational life, resistant to wear. | Important for reducing replacement costs and ensuring reliability in trade. |

| Efficiency | Low power consumption with high torque output. | Crucial for sustainability and reducing operational costs in global markets. |

| Control Flexibility | Compatible with various control systems and protocols. | Increases adaptability in diverse applications across different markets. |

| Noise Level | Low operational noise, suitable for quiet environments. | Enhances the appeal for applications in consumer-oriented markets. |

How to Identify Reliable Manufacturers for Stepper Motors in China

When navigating the global landscape of stepper motor manufacturing, especially in China, identifying reliable manufacturers is crucial for ensuring quality and performance. One effective strategy is to assess a manufacturer's certifications and quality management systems. Look for certifications such as ISO 9001, which indicates a commitment to quality assurance practices. These certifications serve as a benchmark, reassuring buyers that the manufacturer adheres to international quality standards.

Additionally, engaging in thorough due diligence is essential. This includes researching the manufacturer through online platforms, customer reviews, and testimonials. Attending industry trade shows or exhibitions can provide direct insights into manufacturer capabilities and product offerings. Establishing clear communication with potential suppliers is also vital; ask detailed questions about their production processes, material sourcing, and testing protocols. A manufacturer that is transparent about their operations and willing to provide references is likely to be a trustworthy partner in your global trade endeavors.

Ensuring Quality Control in the Production of Integrated Stepper Motors

Ensuring quality control in the production of integrated stepper motors has become paramount in the global trade landscape, especially with China's notable advancements in manufacturing. Recent initiatives, including the “Quality Strong Nation Construction Outline” released by the Central Committee of the Communist Party of China and the State Council, underline the country’s commitment to enhance quality standards across various industries. Such governmental measures are crucial for establishing a robust framework that not only boosts local manufacturers but also aligns with international expectations for quality.

As companies navigate the complexities of international markets, maintaining stringent quality control throughout the production process of integrated stepper motors is essential. The adoption of advanced technologies, such as digital twins and AI-based quality control systems, can significantly improve manufacturing efficiency and product reliability. By integrating these innovative measures, businesses can ensure that their integrated stepper motors meet high-performance standards and minimize production flaws. This proactive approach will bolster consumer confidence and ultimately strengthen China’s position as a leader in the global market for quality integrated stepper motors.

Navigating the Supply Chain for Trustworthy Stepper Motor Products

In the realm of global trade, ensuring the quality and reliability of stepper motors is paramount for businesses seeking to maintain a competitive edge. The supply chain for these components, particularly those manufactured in China, can be complex. It's essential to navigate this landscape carefully to source trustworthy products. Establishing strong relationships with trusted suppliers is crucial. Look for those that have a proven track record in quality assurance, certifications, and transparency in their manufacturing processes.

**Tip:** Always request samples before placing large orders. This allows you to assess the motor’s performance and reliability firsthand, ensuring it meets your specific requirements and standards.

Moreover, invest time in understanding the regulations and certifications that apply to stepper motors. Different countries have unique requirements, and compliance can affect not only product quality but also market acceptance. Regular audits and quality checks can help in evaluating supplier performance and maintaining the standard you desire.

**Tip:** Utilize technology to manage your supply chain effectively. Implementing data analytics and tracking systems can provide insights into supplier reliability and product quality, helping you make informed decisions.