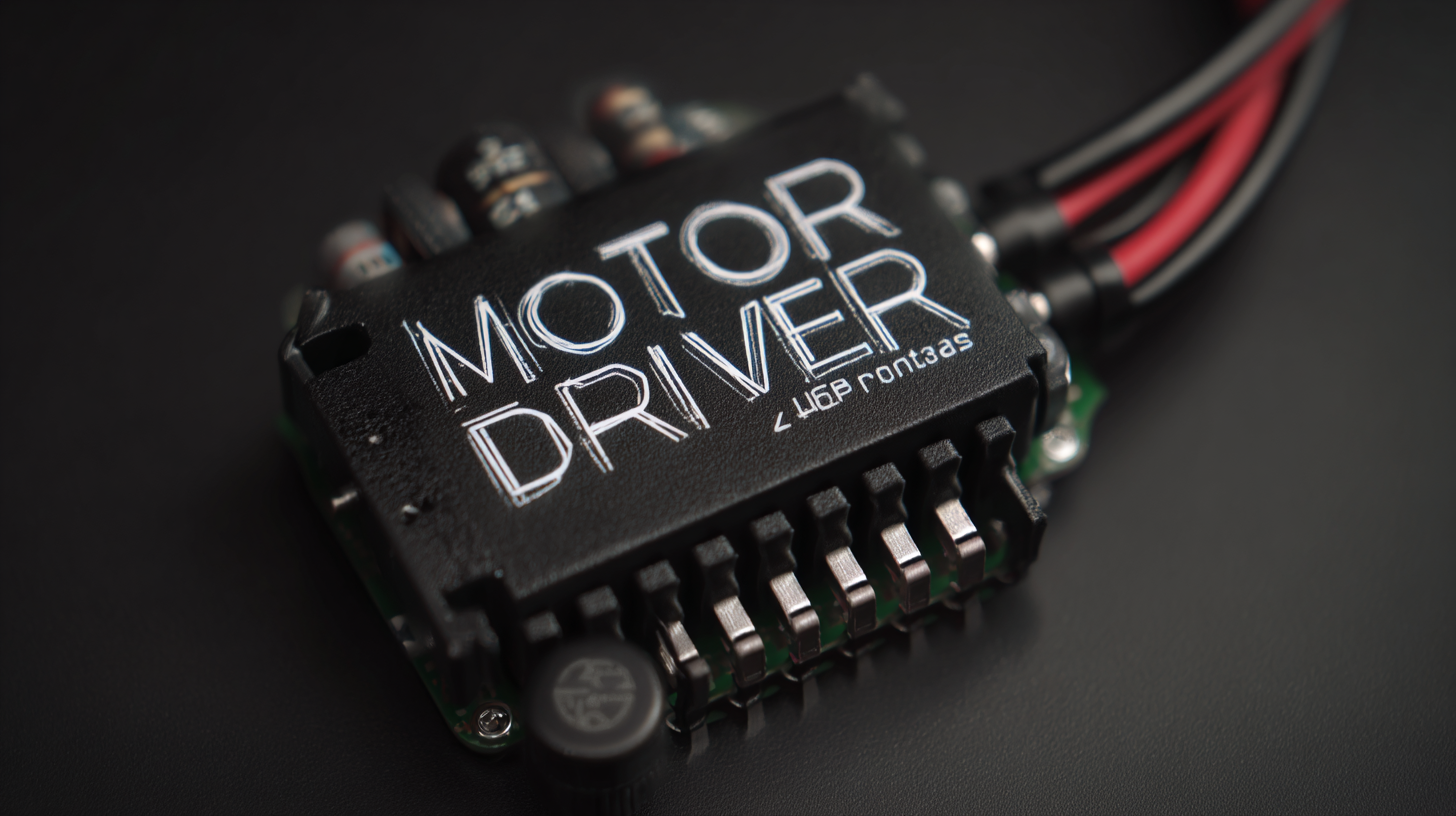

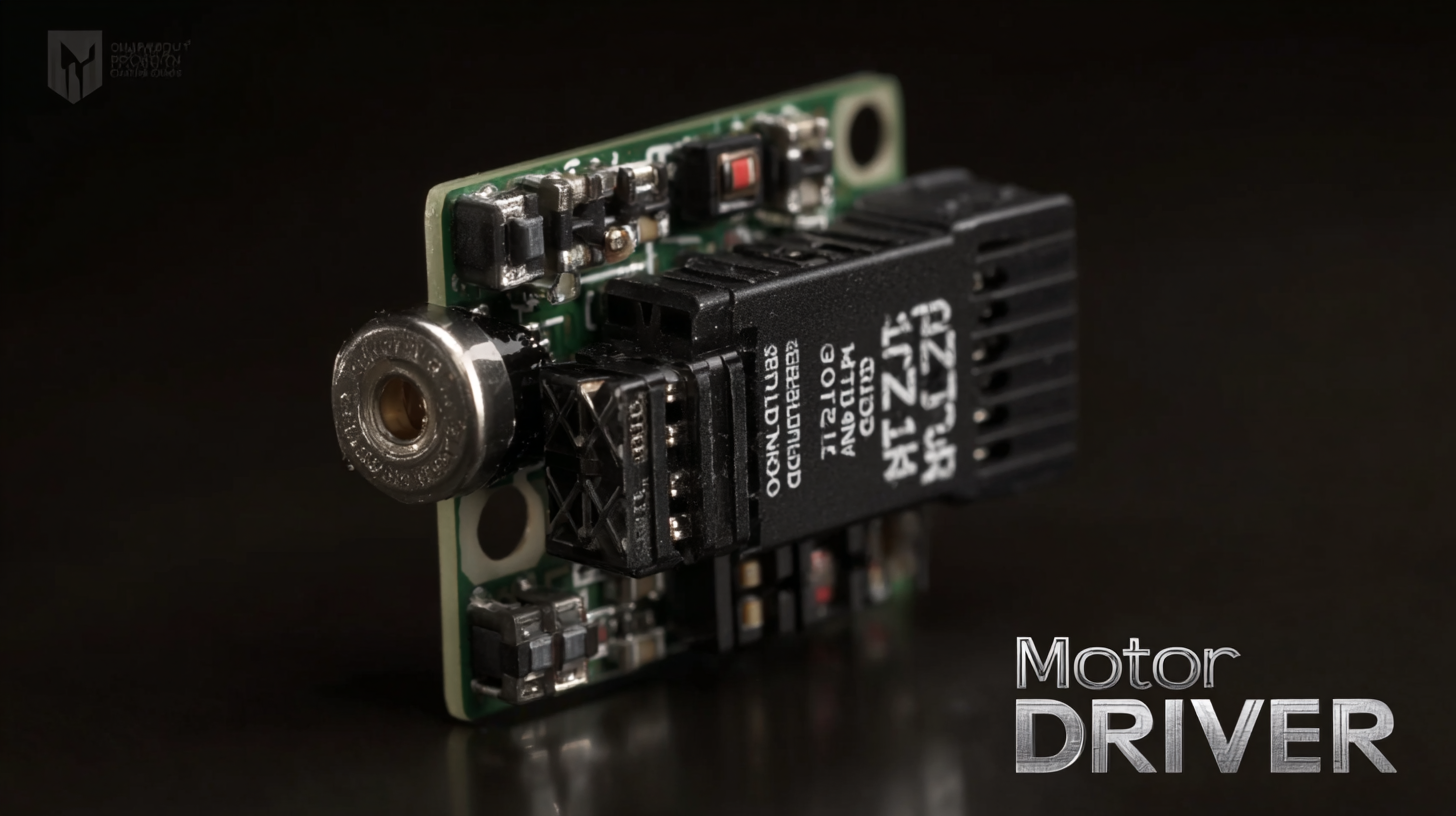

Unveiling the Ultimate Specifications of the Best Motor Driver for Global Buyers

In today's fast-paced industrial landscape, the demand for efficient and reliable motor drivers has surged, driven by the rapid advances in automation and robotics. According to a recent market research report from MarketsandMarkets, the global motor driver market is projected to grow from USD 3.76 billion in 2020 to USD 5.14 billion by 2025, at a compound annual growth rate (CAGR) of 6.8%. This growth is fueled by the increasing adoption of electric vehicles, smart home appliances, and industrial automation systems, which rely heavily on motor driver technology. As industries across various sectors seek to optimize performance and enhance energy efficiency, understanding the specifications and capabilities of the best motor drivers becomes crucial for global buyers. In this blog, we will delve into the essential specifications that define the top motor drivers in the market, backed by real-world application cases that highlight their industry relevance and functionality.

Choosing Quality Manufacturers: What to Look For in Motor Driver Production

When selecting a motor driver, it's crucial to focus on the quality of the manufacturers involved in its production. A reputable manufacturer will demonstrate a commitment to high standards of quality control and engineering excellence. Prospective buyers should inquire about the maker's industry certifications and adherence to international safety and performance standards. Such credentials not only indicate a manufacturer’s dedication to quality but also assure buyers of the reliability of their products.

Additionally, evaluating the manufacturer’s track record is essential. Look for companies with a proven history of innovation and customer satisfaction. Online reviews, case studies, and testimonials can provide valuable insights into the manufacturer’s capabilities and reliability.

It’s also beneficial to assess their technical support and after-sales service, as these factors can significantly impact the long-term performance of your motor driver. By prioritizing these aspects, global buyers can make informed choices and ensure they invest in the best solutions for their applications.

Top Features to Consider for the Best Motor Drivers in the Market

When selecting the best motor drivers for diverse applications, several crucial features come into play. First and foremost, efficiency is a key consideration. According to a recent industry report by ResearchAndMarkets, the global market for motor drivers is projected to grow at a CAGR of 7.2% from 2021 to 2026, driven in part by the increasing demand for energy-efficient solutions in automated systems. A motor driver with a high efficiency rating minimizes energy loss, translating to lower operational costs and a reduced carbon footprint.

Another vital aspect to consider is the compatibility of the motor driver with various communication protocols. In contemporary industrial applications, seamless integration with IoT devices and smart technology is essential. A report from MarketsandMarkets highlights that around 80% of manufacturing firms prioritize compatibility with protocols such as CAN, RS-485, and Ethernet when choosing motor drivers. This flexibility facilitates smoother data exchange and more efficient control, essential for maintaining competitiveness in today's fast-paced market.

Lastly, thermal management features cannot be overlooked. Effective heat dissipation is necessary to maintain the longevity and reliability of motor drivers. Data from Semiconductor Engineering indicates that advanced thermal management techniques can enhance the performance of motor drivers by up to 30%, ensuring they operate efficiently under varying load conditions. Overall, paying attention to these specifications will help global buyers make informed choices in the bustling market of motor drivers.

Essential Specifications That Define High-Performance Motor Drivers

When selecting a high-performance motor driver, understanding the essential specifications is crucial for making an informed decision. One of the primary specifications to consider is the voltage and current ratings of the driver. A motor driver needs to efficiently manage the voltage output while providing sufficient current to the motor for optimal performance. This balance ensures that the driver can handle various operating conditions without risking damage to the motor or the driver itself.

Another significant specification is the control type, which can be classified into PWM (Pulse Width Modulation), analog, or digital control. Each type offers distinct advantages depending on the application. PWM control, for instance, is widely preferred for its efficiency and ability to reduce power consumption while maintaining torque and speed control. Additionally, built-in protection features such as overcurrent, thermal shutdown, and undervoltage lockout contribute greatly to the longevity and reliability of motor drivers, making them critical elements to assess when hunting for the best option in the market.

Digital Insights: Comparing Motor Driver Types for Optimal Selection

When choosing a motor driver, understanding the various types available on the market is essential for making an optimal selection. According to a report by MarketsandMarkets, the global motor driver market is expected to grow from $1.8 billion in 2023 to $3.0 billion by 2028, at a compound annual growth rate (CAGR) of 10.5%. This growth is primarily driven by the increasing demand for automation in industries like manufacturing and electric vehicles.

Among the different types of motor drivers, brushless DC (BLDC) drivers have gained significant popularity due to their high efficiency and reliability. A comparative study by ResearchAndMarkets highlighted that BLDC motors consume 20-30% less energy compared to their brushed counterparts, making them ideal for applications where energy efficiency is paramount. On the other hand, stepper motor drivers are preferred in applications requiring precise control of motion, as they can reliably and accurately position loads with repeatable precision, which is crucial in robotics and CNC machinery.

As buyers compare motor driver specifications, it is vital to consider these insights, focusing on energy efficiency, application suitability, and overall performance parameters. The growing demand for intelligent and sustainable solutions further emphasizes the need for selecting the right motor driver type, ensuring both operational effectiveness and cost efficiency in the long run.

Comparative Analysis of Motor Driver Types

Global Buying Trends: How to Choose the Right Motor Driver for Your Needs

When selecting the right motor driver, understanding global buying trends is crucial. As technology rapidly evolves, buyers are increasingly looking for motor drivers that boast efficiency, versatility, and compatibility with various applications. Whether for robotics, automation, or electric vehicles, knowing what’s popular and effective in the market can guide your decision-making process.

**Tips:** Focus on the specifications that matter to you. Look for drivers that provide high current output and efficient thermal management. An ideal motor driver should also support a range of motor types, such as stepper and DC motors, to ensure compatibility with your projects.

Another trend is the emphasis on integrated solutions. Many buyers prefer motor drivers that come with built-in features like protection against overloads, which helps prevent damage to your components. This added safety factor can save you time and resources down the line.

**Tips:** Always consider scalability. Choose a motor driver that allows you to adapt as your projects grow or change. A driver with adjustable parameters can give you flexibility for different applications, making it a smart investment for the future.

Unveiling the Ultimate Specifications of the Best Motor Driver for Global Buyers - Global Buying Trends: How to Choose the Right Motor Driver for Your Needs

| Specification | Details | Typical Applications |

|---|---|---|

| Supply Voltage | 5V to 36V | Robot motors, drones |

| Current Rating | 2A continuous, 3A peak | 3D printers, CNC machines |

| Control Method | PWM, Direction Control | Electric vehicles, industrial automation |

| Protection Features | Overcurrent, thermal shutdown | Robotics, home automation |

| Interface Type | Digital, I2C, Serial | Smart appliances, IoT devices |

| Dimensions | 30mm x 40mm | Portable devices, wearable technology |

| Operating Temperature | -20°C to 85°C | Outdoor applications, automotive |