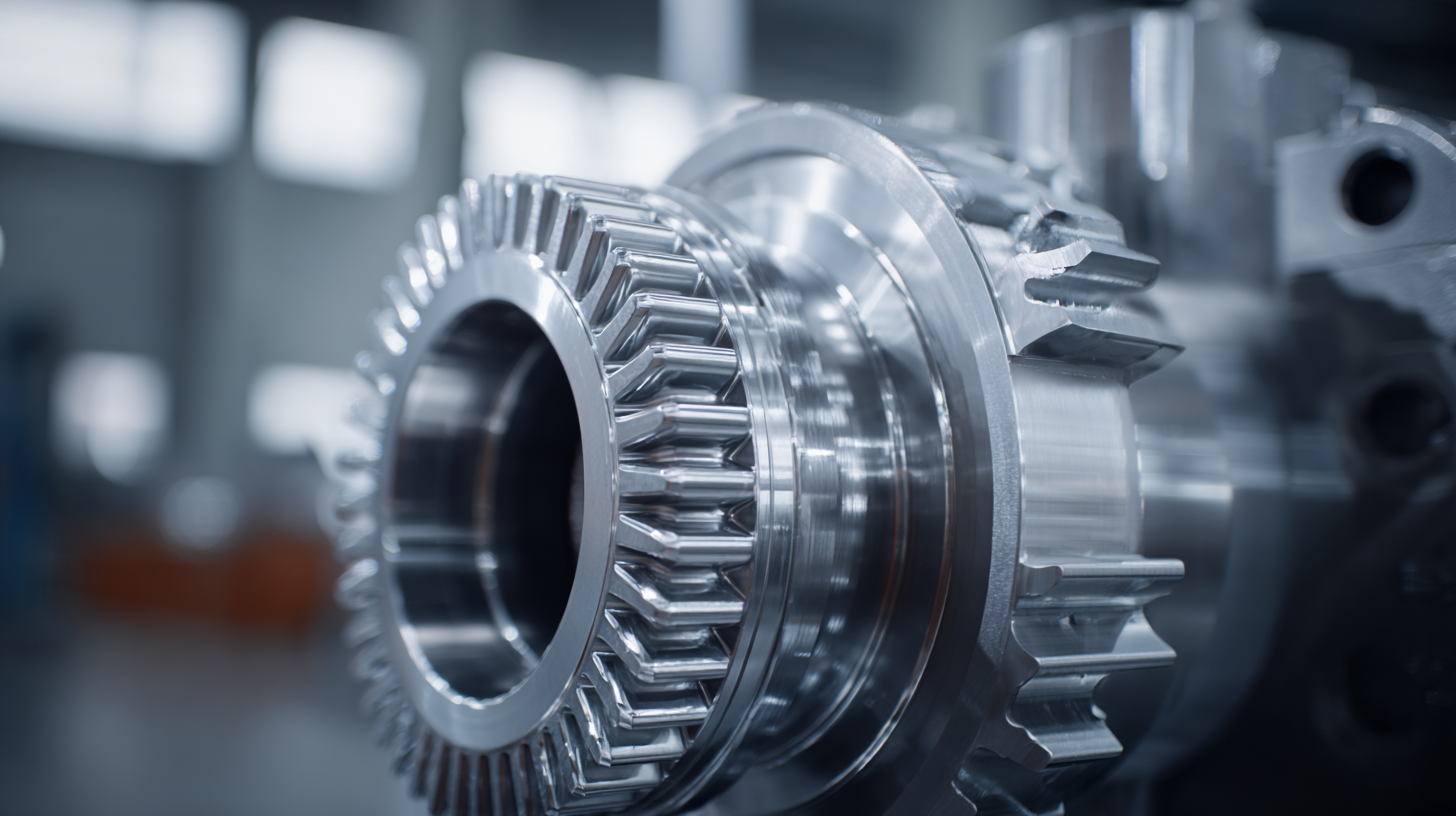

Understanding Gear Reducers: The Hidden Power Behind Efficient Machinery Performance

In the realm of machinery and equipment performance, gear reducers play a crucial yet often overlooked role. These powerful components are engineered to modify the output speed and torque of mechanical systems, enhancing efficiency and effectiveness in a variety of applications. Understanding how gear reducers function and their significance can empower engineers, technicians, and machine operators to maximize machinery capabilities and optimize operations. In this guide, we will explore the fundamentals of gear reducers, including their design, operational principles, and the benefits they offer across different industries. By shedding light on the intricacies of gear reducers, we aim to provide valuable insights that will help you harness their hidden power for improved machinery performance.

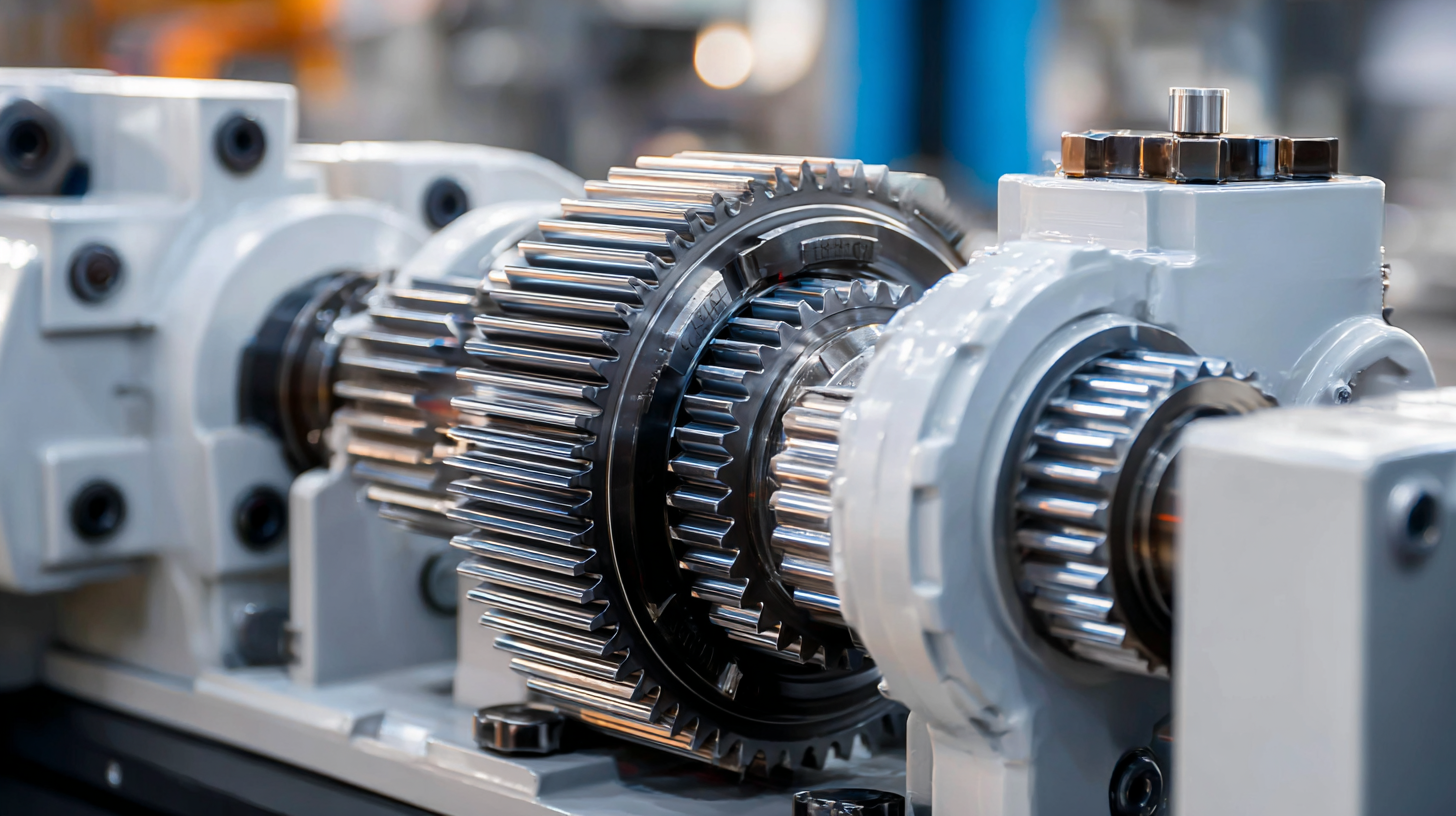

Key Functions of Gear Reducers in Machinery Efficiency

Gear reducers play a pivotal role in enhancing the efficiency of machinery, particularly in the realm of industrial automation, where they account for approximately 70% of applications. Their primary function is to decrease the output speed while increasing torque, thereby optimizing performance in various systems such as robotics, conveyor belts, and manufacturing processes. As the demand for more efficient and powerful actuators grows, innovations such as compact, high-power gear reducers are being developed to meet the needs of advanced robotic applications.

Recent advancements highlight the significance of gear reducers in transforming robotic design. For instance, the shift towards direct drive mechanisms—with minimal reliance on traditional reducers—has sparked considerable interest within the industry. Such innovations not only contribute to a more agile robotic design but also align with ongoing trends aimed at sustainability and efficiency. Detailed analysis of core components, including sensors, motors, and gear reducers, reveals the intricate relationship between these elements and the overall performance of robotic systems, emphasizing the essential functions of gear reducers in the unfolding landscape of modern machinery.

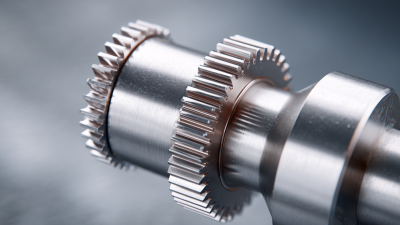

Essential Parameters to Consider When Choosing Gear Reducers

When it comes to selecting gear reducers for efficient machinery performance, understanding the essential parameters is crucial. Key factors such as

gear ratio, load capacity, and efficiency ratings play a significant role in determining the overall effectiveness of a gear reducer. The gear ratio, which indicates the relationship between the input and output speeds, directly affects torque and performance. Higher gear ratios can provide greater torque, making them suitable for heavy-duty applications.

Tips: When choosing a gear reducer, assess the load capacity carefully to ensure it can handle the operational demands without compromising performance or lifespan. Additionally, look for reducers with high efficiency ratings; a reduction in energy loss translates to better performance and lower operational costs.

Another critical aspect to consider is the material and construction quality of the gear reducer, which influences durability and maintenance needs. Investing in high-quality gear reducers can lead to a more reliable and efficient machinery system.

Tips: Don’t overlook the importance of checking the manufacturer's specifications and reviews. A well-reviewed product can offer insights into real-world performance and potential issues that may not be immediately apparent. Understanding these essential parameters will empower you to make informed choices that enhance your machinery's productivity.

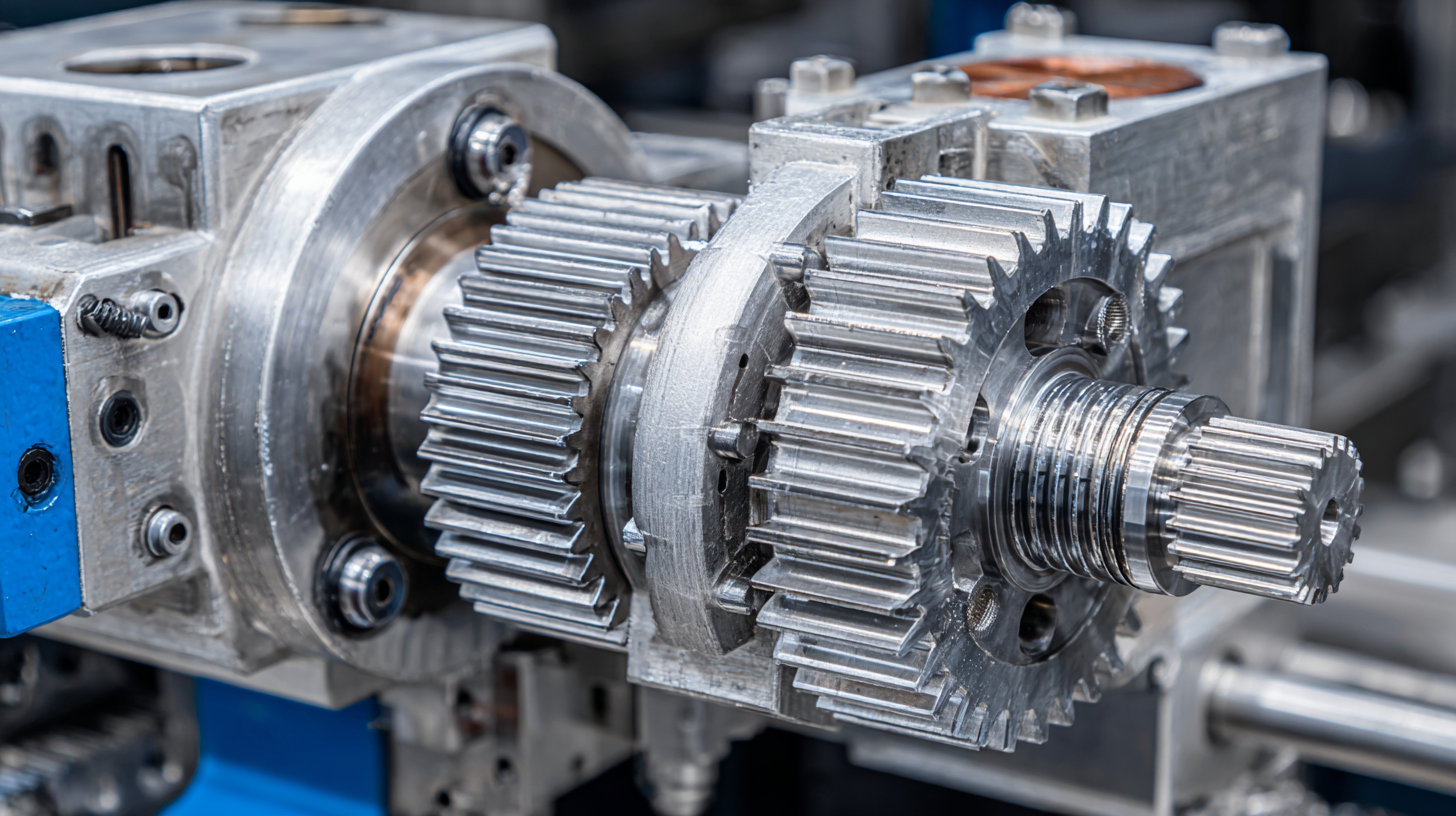

Common Applications of Gear Reducers in Industry Today

Gear reducers play a crucial role in enhancing the efficiency of machinery across various industries, particularly in small mobility applications. For instance, planetary gears are being increasingly utilized in innovative solutions like

autonomous plant inspection robots and all-terrain vehicles. Their ability to provide substantial torque while maintaining a compact form factor makes them ideal for applications where

space and performance are paramount. As the industry evolves, these compact gear systems are proving essential for achieving higher operational reliability and efficiency in automated machinery.

The global industrial gearbox market is witnessing significant growth, with estimates showing a rise from USD 30.6 billion in 2024 to over USD 47.5 billion by 2034, reflecting a compound annual growth rate (CAGR) of around 4%. This growth can be attributed to the increasing demand for advanced mobility solutions, particularly in sectors such as

robotics and automation, where efficient power transmission is critical. Reports indicate that the industrial gearbox market was valued at approximately USD 32.9 billion in 2025,

with projections showing it could reach USD 51.6 billion by 2035, driven by ongoing advancements in technology and manufacturing processes. These trends underscore the importance of gear reducers in achieving optimal performance in modern industrial applications.

Maintenance Tips for Prolonging the Life of Gear Reducers

Proper maintenance of gear reducers is crucial for ensuring their longevity and maintaining high efficiency in machinery performance. Regular inspections should be a routine practice, focusing on checking for any signs of wear or damage in the gears and bearings. Listening for unusual noises during operation can also be an early indicator of potential issues. If abnormal sounds are detected, it's essential to investigate promptly to avoid more significant problems down the line.

Lubrication plays a vital role in the performance of gear reducers. Using the appropriate type and amount of lubricant helps reduce friction and heat buildup, which are detrimental to the functioning of the gears. It's imperative to follow the manufacturer's guidelines regarding lubrication frequency and type. Additionally, monitoring the operating temperature can help identify any irregularities that may suggest the need for maintenance or lubrication adjustments. By implementing these maintenance tips, operators can significantly extend the life of their gear reducers, ensuring reliable and efficient machinery performance.

Innovative Technologies Enhancing Gear Reducer Performance

Innovative technologies are continuously transforming the landscape of gear reducers, enhancing their performance and efficiency in various machinery applications.

One of the groundbreaking advancements is the integration of smart sensors and IoT connectivity.

By enabling real-time monitoring and data analytics, these technologies allow engineers to optimize the performance of gear reducers more effectively.

Predictive maintenance can now be implemented, reducing downtime and extending the lifespan of machinery, ultimately leading to significant cost savings for businesses.

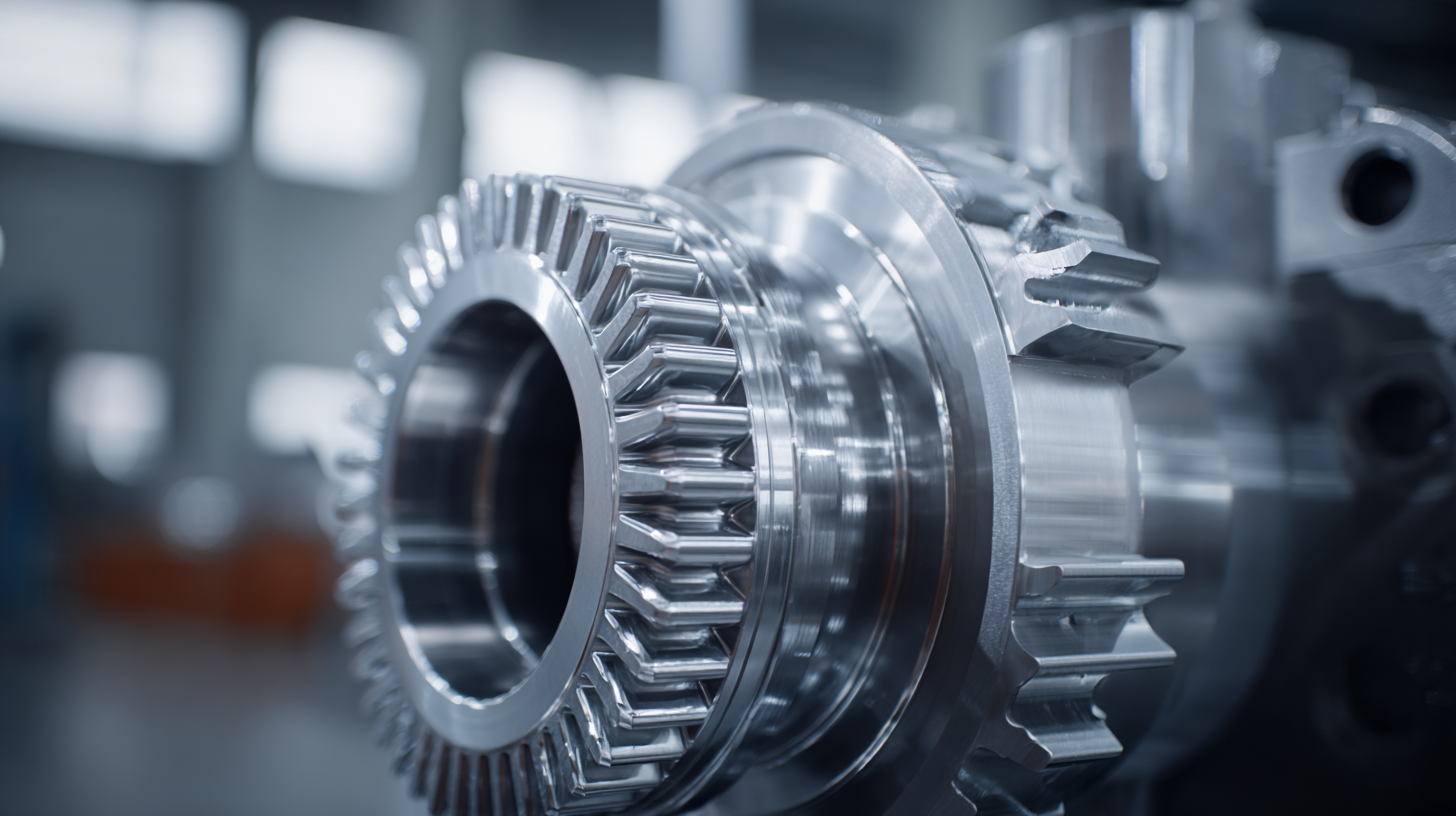

Moreover, advancements in materials science have led to the development of lightweight and durable components capable of withstanding higher loads and providing more efficient power transmission.

Innovations such as advanced coatings and composite materials enhance the wear resistance and thermal stability of gear reducers, allowing them to operate under extreme conditions.

As a result, the modern gear reducer is not only more reliable but also contributes to overall energy efficiency, aligning with the industry's shift towards sustainability and eco-friendliness.

Through these innovative technologies, gear reducers play a crucial role in optimizing machine performance and driving productivity.