How to Use Precision Technology to Improve Efficiency and Accuracy in Your Business

In the rapidly evolving landscape of modern business, the integration of precision technology has emerged as a transformative force, fundamentally reshaping the way companies operate. According to Dr. Emily Chen, a leading expert in precision technology, “Harnessing the power of precision technology not only enhances operational efficiency but also significantly elevates the accuracy of decision-making processes.” As industries strive to remain competitive, the adoption of technologies that optimize performance and reduce errors has become imperative.

Precision technology encompasses a range of advanced tools and techniques that facilitate precise measurements, analytics, and data processing. By leveraging these innovations, businesses can streamline their workflows, resulting in improved productivity and resource allocation. Dr. Chen emphasizes the importance of these advancements, noting that “with precision technology, businesses can uncover insights that were previously unattainable, ensuring they can make informed decisions swiftly and effectively.”

As we delve into the strategies for utilizing precision technology to enhance business efficiency and accuracy, it is essential to acknowledge the potential and the impact these tools have on shaping the future of industry standards. Through a focused approach on precision, organizations can not only optimize their current operations but also pave the way for sustainable growth in an increasingly data-driven world.

Understanding Precision Technology and Its Role in Business Efficiency

Precision technology, encompassing

advanced data analytics, automation, and

sophisticated process control systems, plays a pivotal role in enhancing

business efficiency and accuracy. According to a report by

McKinsey, organizations that leverage

data-driven decision-making capabilities improve their productivity by

5 to 6 percent. This highlights the significant impact precision technology can

have in streamlining operations and minimizing errors. By utilizing tools such as

machine learning algorithms and IoT devices,

businesses can attain real-time insights, which help in optimizing resources

and reducing operational costs.

To effectively implement precision technology, consider the following tips: Firstly, identify

key performance indicators (KPIs) relevant to your business objectives, and utilize precision tools to monitor these metrics continuously. This will ensure you are making informed decisions based on accurate data.

Secondly, invest in training your workforce on these technologies.

A skilled team can turn insights into actionable strategies, boosting productivity. Lastly, adopt a

test-and-learn approach: implementing precision technologies in phases allows for adjustments based on early results, minimizing disruption while maximizing the benefits of these sophisticated systems.

By embedding precision technology into your operations, you can not only enhance efficiency but also significantly improve overall

business accuracy.

Identifying Key Areas for Precision Technology Implementation

Identifying key areas for implementing precision technology is crucial for driving efficiency and enhancing accuracy in business operations. Start by analyzing your workflow to pinpoint inefficiencies or bottlenecks that could benefit from technological intervention. For instance, inventory management, data analysis, and customer relationship management are classic areas where precision technology can make a significant impact. By streamlining these processes, businesses can reduce errors and optimize resource allocation.

Tip: Consider using data analytics tools to assess where your current processes fall short. Gathering data on production timelines, error rates, and customer feedback can highlight specific areas that require attention.

Additionally, employee training and engagement are vital when integrating precision technology. Ensure that your team understands the tools and processes being implemented. Regular workshops and feedback sessions can facilitate a smoother transition to new technologies, ensuring that employees are not just users but also contributors to the system's success.

Tip: Create a feedback loop where employees can share their experiences and challenges with the new technology. This input can help you refine processes further and boost overall productivity.

Evaluating Tools and Solutions for Precision Technology Integration

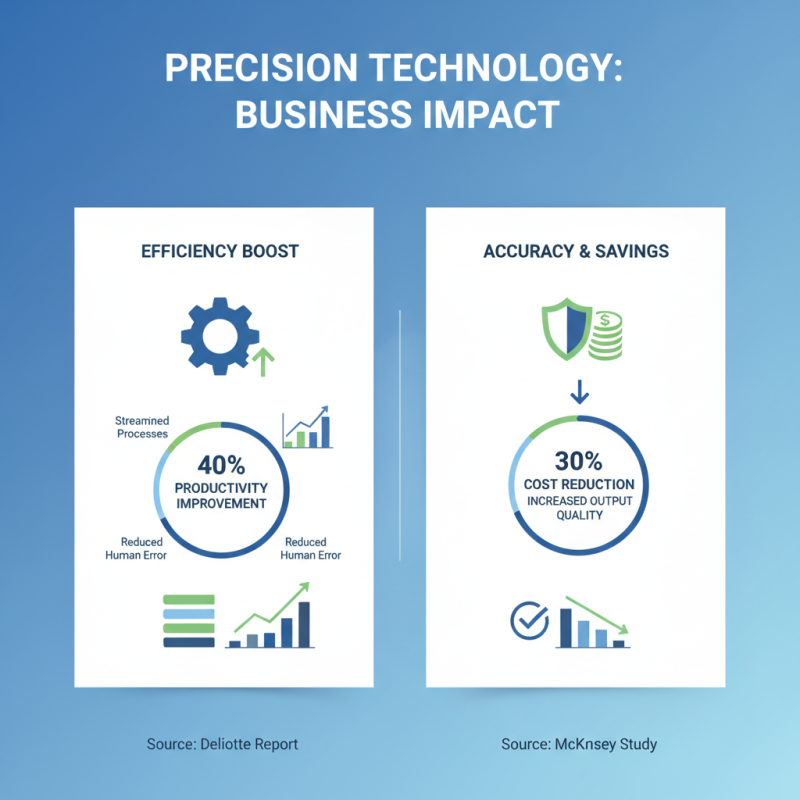

Integrating precision technology into your business operations can significantly enhance both efficiency and accuracy. According to a report by Deloitte, businesses that utilize precision technology, such as advanced data analytics and automation tools, have seen productivity improvements of up to 40%. This substantial increase is mainly attributed to streamlined processes and the reduction of human error in data handling. Furthermore, a McKinsey study found that organizations that adopt precision tools can reduce operational costs by as much as 30% while simultaneously increasing output quality.

When evaluating tools and solutions for precision technology integration, it's crucial to consider the specific needs of your business. Factors like scalability, ease of implementation, and compatibility with existing systems should guide your selection. Research indicates that businesses that invest in tailored precision solutions experience a 20% higher return on investment compared to those that use generic tools. Analytics platforms, for instance, can provide insights that drive better decision-making and resource allocation, aligning operations closely with strategic goals. Ultimately, leveraging the right precision technologies not only fosters improved efficiency but also positions businesses competitively in an increasingly data-driven market.

Measuring the Impact of Precision Technology on Business Outcomes

Precision technology plays a crucial role in enhancing business outcomes by optimizing processes and minimizing errors. By integrating advanced data analytics and automation tools, businesses can track performance metrics more accurately, leading to better decision-making. This increased accuracy enables companies to identify inefficiencies and address them proactively, resulting in a streamlined workflow that boosts productivity. For example, precision technology can assist in inventory management, where real-time data helps businesses maintain optimal stock levels, reducing waste and ensuring customer satisfaction.

The impact of precision technology on business outcomes can be measured through key performance indicators such as operational efficiency, cost reduction, and increased revenue. Businesses that adopt precision approaches often see a decrease in operational costs as they utilize resources more effectively. Furthermore, with enhanced data collection and analysis, organizations can gain insights into customer behavior and preferences, allowing for more targeted marketing strategies and improved customer engagement. These improvements not only contribute to a better bottom line but also foster long-term growth by establishing a reputation for reliability and innovation in the marketplace.

Best Practices for Sustaining Precision Technology Improvements

Implementing precision technology in business can significantly enhance operational efficiency and accuracy. To sustain improvements brought by such technology, organizations must establish best practices that foster continuous monitoring and adaptation. One key practice is to regularly evaluate the technology's performance against set benchmarks. This ensures that the systems are functioning as intended and provides insight into potential areas for enhancement.

Another important aspect is training and development. Employees should receive ongoing training to stay updated with the latest advancements in precision technology. This not only empowers them to utilize the tools effectively but also encourages a culture of innovation within the organization. Additionally, fostering an environment of open communication allows teams to share insights and feedback, which can lead to further optimization of processes and technologies in use.

Maintaining strong vendor relationships is also crucial for sustaining precision technology improvements. Collaborating closely with technology providers enables businesses to access support, updates, and innovations that can enhance their existing systems. Engaging in regular dialogues about performance and potential upgrades ensures that the technology continues to align with the evolving needs of the business. By adhering to these best practices, organizations can maximize the long-term benefits of precision technology.

How to Use Precision Technology to Improve Efficiency and Accuracy in Your Business - Best Practices for Sustaining Precision Technology Improvements

| Dimension |

Current Value |

Target Value |

Improvement Percentage |

| Production Efficiency |

75% |

90% |

20% |

| Error Rate |

5% |

1% |

80% |

| Customer Satisfaction |

85% |

95% |

12% |

| Waste Reduction |

30% |

10% |

66% |

| Lead Time |

10 days |

5 days |

50% |