2026 How to Use a Worm Drive for Maximum Efficiency in Your Projects?

In the world of mechanical engineering, the term "worm drive" signifies a unique gearing system. Known for its efficiency, a worm drive converts rotary motion into linear motion with minimal energy loss. According to a recent industry report from the Gear Manufacturers Association, worm drives remain popular in applications requiring precise control, achieving 90% efficiency in optimal conditions.

Expert Mark Johnson, a renowned figure in the field, emphasizes, "Optimizing a worm drive is key to enhancing project results." This highlights the importance of understanding how to use these drives effectively. Yet, many engineers overlook the nuances required for maximum efficiency.

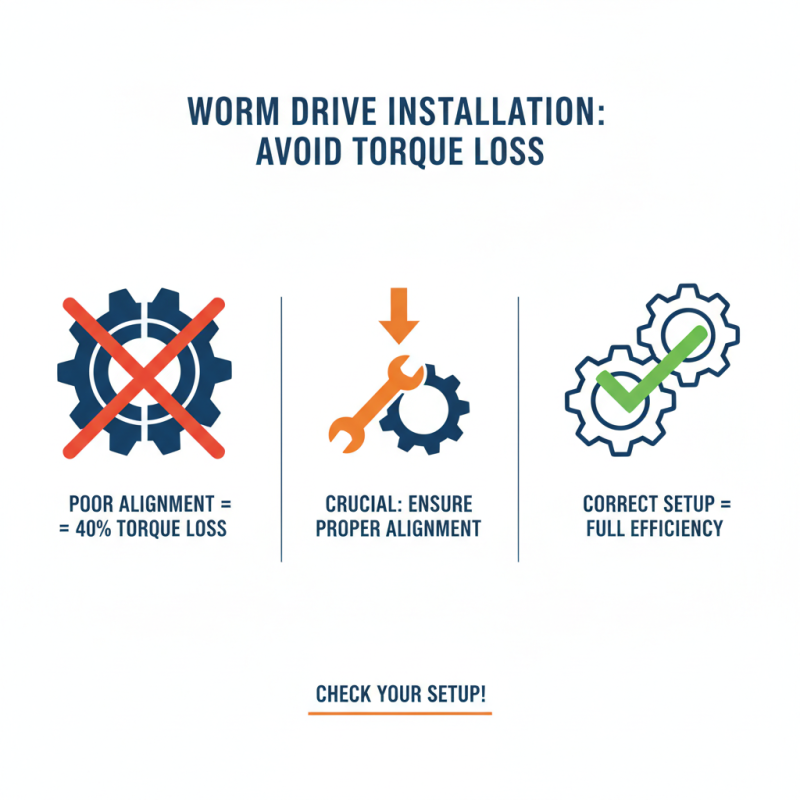

Common mistakes include improper alignment and inadequate lubrication. These issues can lead to performance losses. Simply relying on standard practices isn't enough. Engineers must analyze the specific load and application needs. Understanding these details will ultimately lead to better project outcomes. In a rapidly evolving industry, failing to adapt could result in inefficiencies that undermine project success.

Understanding Worm Drives: Definition and Key Components

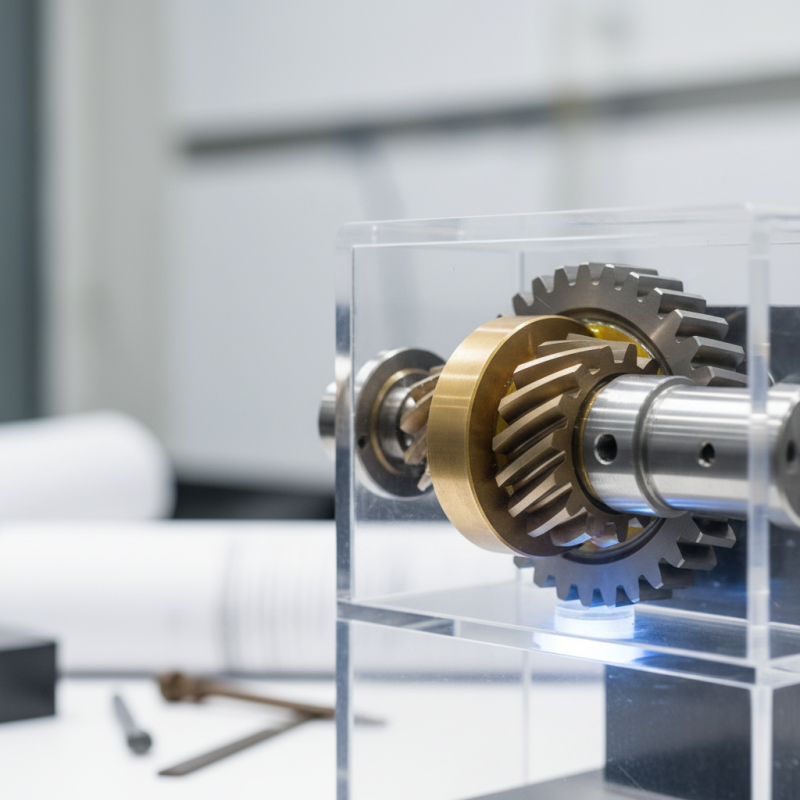

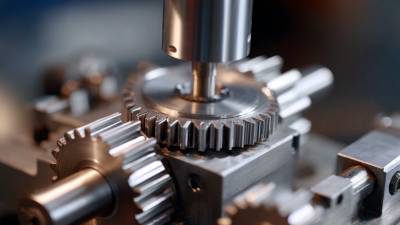

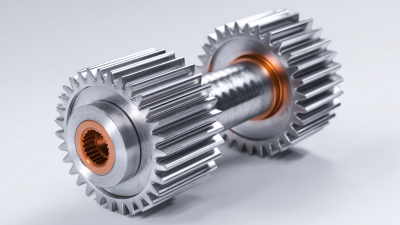

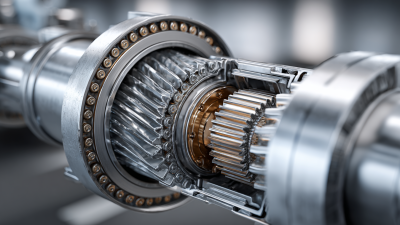

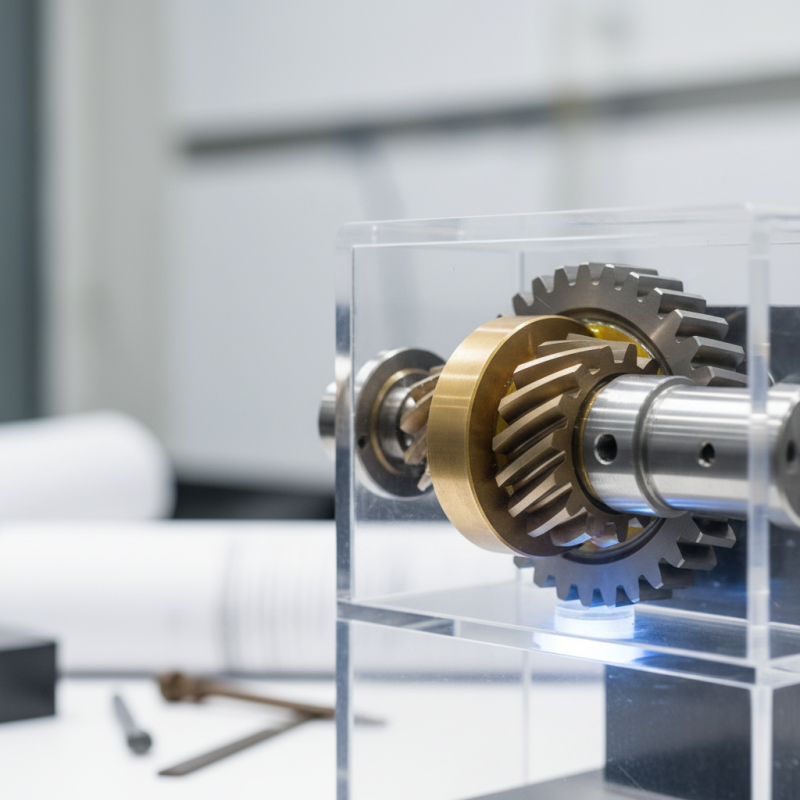

Worm drives are a unique type of gear system often used in various projects. They consist of a worm (a screw-like component) and a worm wheel (a gear). This design allows for high torque and reduced speed. The key components make it efficient for applications like lifts, conveyor systems, and even small machinery.

Understanding these elements is crucial. The worm's design enables it to mesh with the worm wheel smoothly. However, this interaction can lead to challenges, such as wear over time. It's important to monitor the condition of these parts. Regular maintenance can prevent inefficiencies. It's a delicate balance between power output and durability.

In design, consider the load requirements. Too much load can stress the worm drive, which may lead to breakdowns. Not all projects require the same specifications. Some might face significant reductions in efficiency if the wrong worm drive is chosen. Reflecting on the needs of your project will help in selecting the right gear system.

Advantages of Using Worm Drives in Various Applications

Worm drives are unique gear systems favored for their high torque and compact design. They excel in applications requiring speed reduction while increasing output torque.

For instance, in conveyor systems, these drives efficiently move heavy loads, maximizing productivity without requiring excessive power. This efficiency is vital in manufacturing where every second counts.

Another advantage is their ability to function quietly and smoothly. This makes them suitable for installations in settings where noise reduction is essential.

In robotics, for example, worm drives allow precise control without the clatter of traditional gears. Yet, they may generate heat, which requires careful management. Users must always account for this factor to avoid unnecessary wear.

These drives also have a self-locking feature, preventing backward movement. This characteristic is crucial in applications like lifting systems. However, while worm drives can offer numerous benefits, they may not be optimal for every scenario. An understanding of the specific requirements of a project is essential. Over-reliance on one type of drive might lead to inefficiencies in different environments.

Maintenance Tips for Ensuring Long-term Performance of Worm Drives

Worm drives are essential in many mechanical applications. Regular maintenance is crucial for their longevity and efficiency. According to industry reports, proper lubrication significantly increases the lifespan of worm drives. A well-maintained worm drive can function effectively for over 10,000 hours, reducing operational downtime.

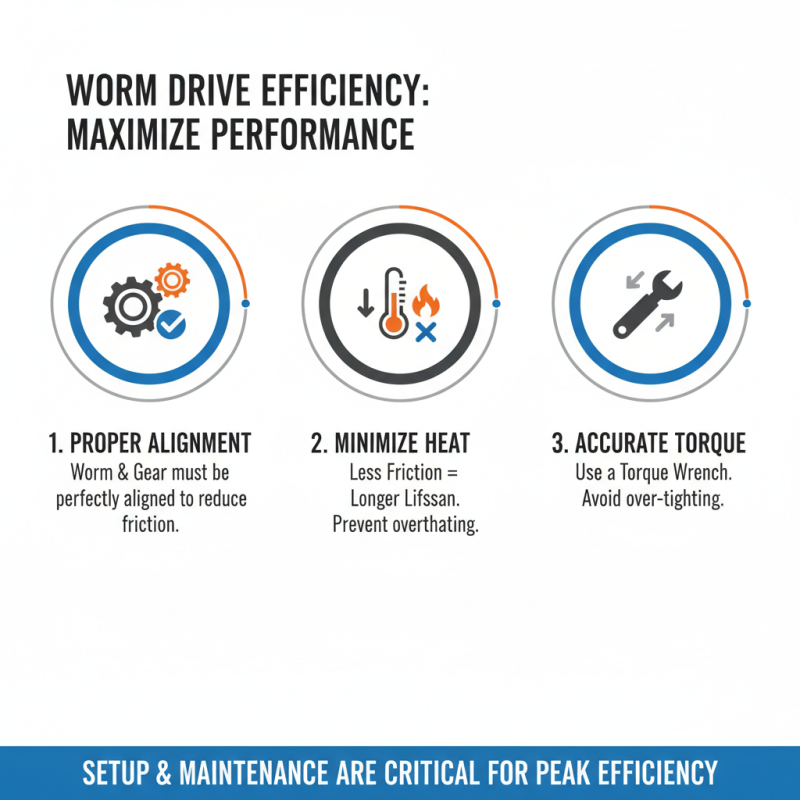

Lubricating a worm drive must be done correctly. Too much grease can lead to overheating. Conversely, too little grease can cause excessive wear. Engineers recommend using high-quality lubricants specifically designed for gear applications. Routine checks are necessary to ensure the lubricant is clean and effective.

Adjustment of the drive's alignment is vital. Misalignment can lead to premature failure. Ensuring correct alignment can reduce noise and vibrations, enhancing operational efficiency. A survey indicated that over 30% of worm drive failures result from misalignment. Monitoring temperature can also provide useful insights. Elevated temperatures often indicate underlying issues. Thus, it is essential to implement a routine check to observe these parameters consistently.