Why Worm Drive Mechanisms Are Essential for Your Mechanical Projects

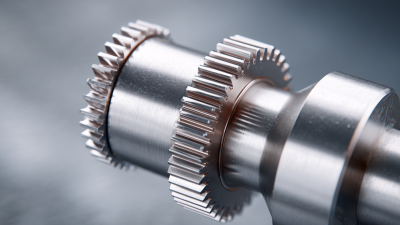

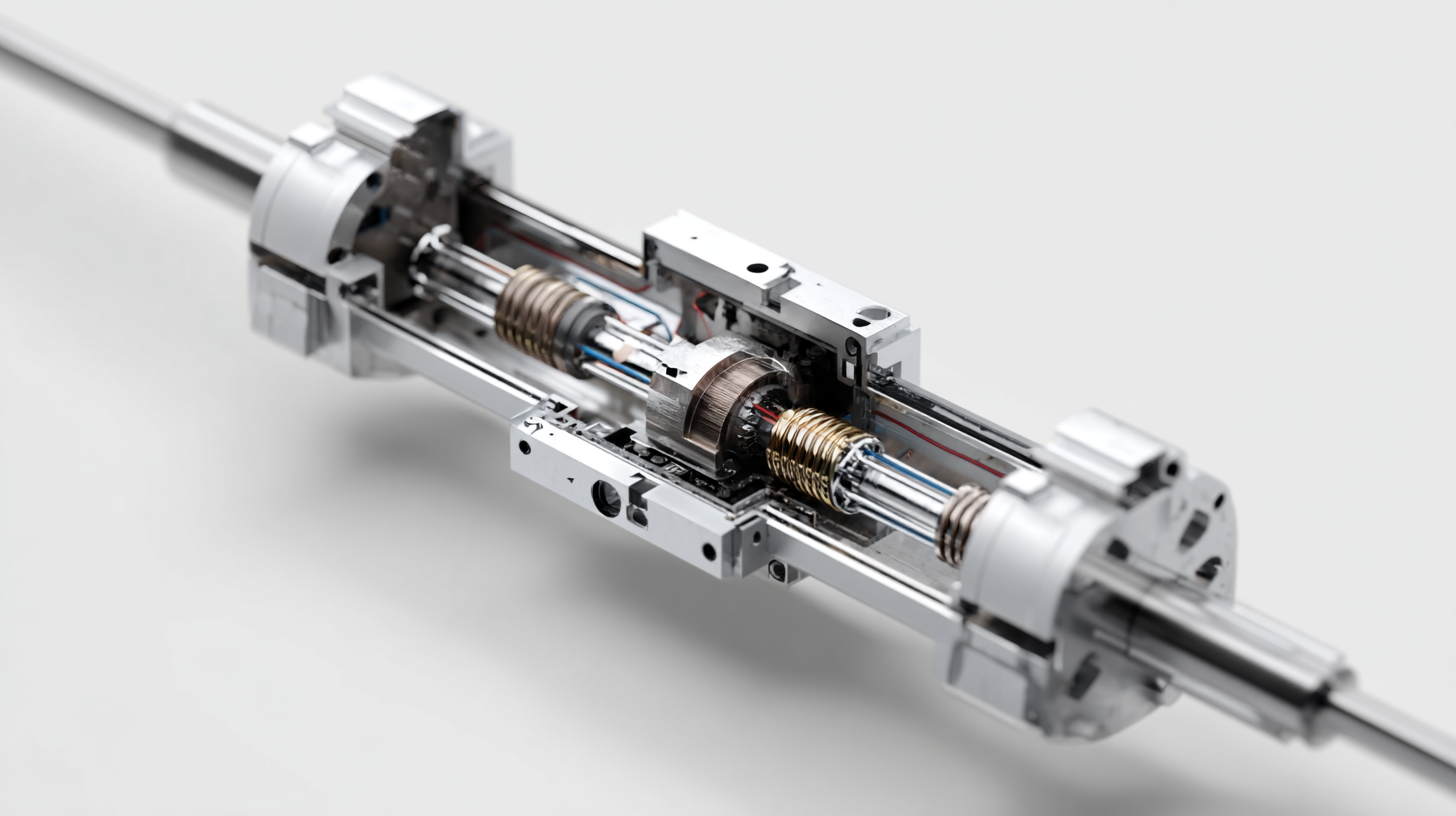

In the realm of mechanical engineering, the importance of precision and reliability cannot be overstated, especially when incorporating unique components like the worm drive. According to a 2022 report by MarketsandMarkets, the global gear drive market is projected to reach USD 25.2 billion by 2026, with worm gears accounting for a significant segment due to their ability to provide high torque and compact design. Worm drives are crucial in various applications ranging from automotive transmissions to aerospace mechanisms, where efficient power transmission and space efficiency are paramount. Furthermore, industry experts note that worm drives are favored for their inherent ability to create a mechanical advantage, providing superior speed reduction in limited spaces. As mechanical projects continue to evolve, understanding the advantages and integrating worm drive technology becomes essential for achieving optimal performance and durability.

Understanding Worm Drive Mechanisms: Key Features and Benefits

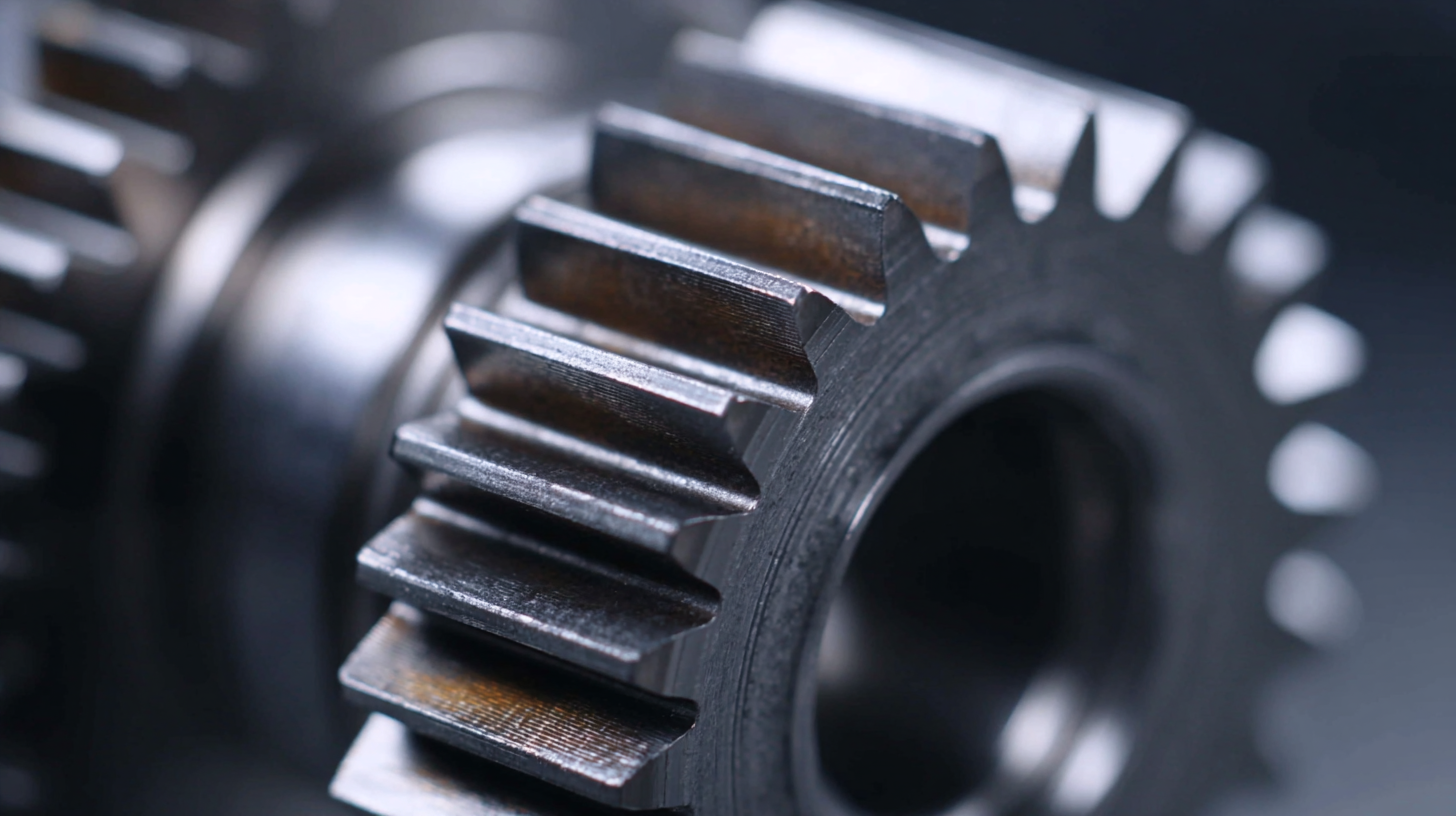

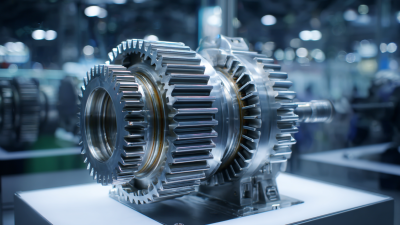

Worm drive mechanisms are integral components in various mechanical projects, offering unique features that enhance performance and efficiency. One of their key characteristics is the ability to achieve high reduction ratios within a compact space. According to a report by The American Gear Manufacturers Association, worm gears can provide reduction ratios as high as 100:1, which is particularly valuable in applications where space is limited and precise control of speed and torque is required.

Another significant benefit of worm drives is their self-locking property, which prevents back driving and maintains position without the need for additional braking systems. This feature is particularly beneficial in applications such as conveyor systems and elevators, where safety and reliability are paramount. A study from the International Journal of Advanced Manufacturing Technology indicates that this self-locking characteristic can lead to reduced operational costs by minimizing the need for external control mechanisms. By integrating worm drive mechanisms into mechanical designs, engineers can enhance the overall reliability and efficiency of their projects, ultimately contributing to improved performance and longevity of the machinery.

Why Worm Drive Mechanisms Are Essential for Your Mechanical Projects

| Feature |

Description |

Benefits |

| High Torque |

Worm drives provide a mechanical advantage, increasing output torque. |

Ideal for heavy machinery and applications requiring high torque output. |

| Compact Size |

The design allows for a smaller footprint compared to other gear types. |

Saves space in mechanical assemblies and improves design flexibility. |

| Self-Locking Feature |

Worm gear systems naturally resist back-driving due to their design. |

Provides safety and stability in applications where load needs to be held in place. |

| Smooth Operation |

Worm drives operate with less vibration and noise compared to other gear types. |

Quieter operation is beneficial in applications like robotics or medical equipment. |

| Versatile Applications |

Can be used in a wide range of machines and devices. |

Suitable for various industries including automotive, aerospace, and manufacturing. |

Top 5 Applications of Worm Drive Mechanisms in Mechanical Engineering

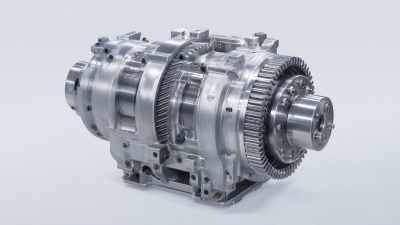

Worm drive mechanisms are a cornerstone in mechanical engineering, offering unique advantages in a variety of applications. Firstly, they excel in scenarios requiring high torque and low speed, making them indispensable in industrial machinery, such as conveyor belts and elevators. According to a report by Grand View Research, the global worm gear market is projected to reach $2.56 billion by 2025, highlighting their growing importance in various sectors.

Another notable application is in the automotive industry. Worm drives are frequently employed in steering gear systems, where precise control is necessary. A study published in the Journal of Mechanical Engineering found that the efficiency of worm gear systems can reach up to 90%, making them an attractive choice for vehicle manufacturers aiming to enhance performance and fuel efficiency. Lastly, worm drives play a crucial role in robotics, where they enable smooth and controlled motion. The increasing adoption of automation reflects a projected annual growth rate of 26% in the robotics sector, further underscoring the significance of worm drives in this rapidly evolving field.

Top 5 Applications of Worm Drive Mechanisms in Mechanical Engineering

3 Reasons to Choose Worm Drives for Precision Motion Control

Worm drive mechanisms are an indispensable choice for precision motion control in various mechanical projects. One of the primary reasons to select worm drives is their ability to provide excellent torque multiplication. The unique gear configuration allows for a significant increase in output torque while minimizing the speed of the driven gear. This characteristic makes worm drives particularly useful in applications where high levels of force are required while maintaining smooth motion, such as in conveyor systems and lifting devices.

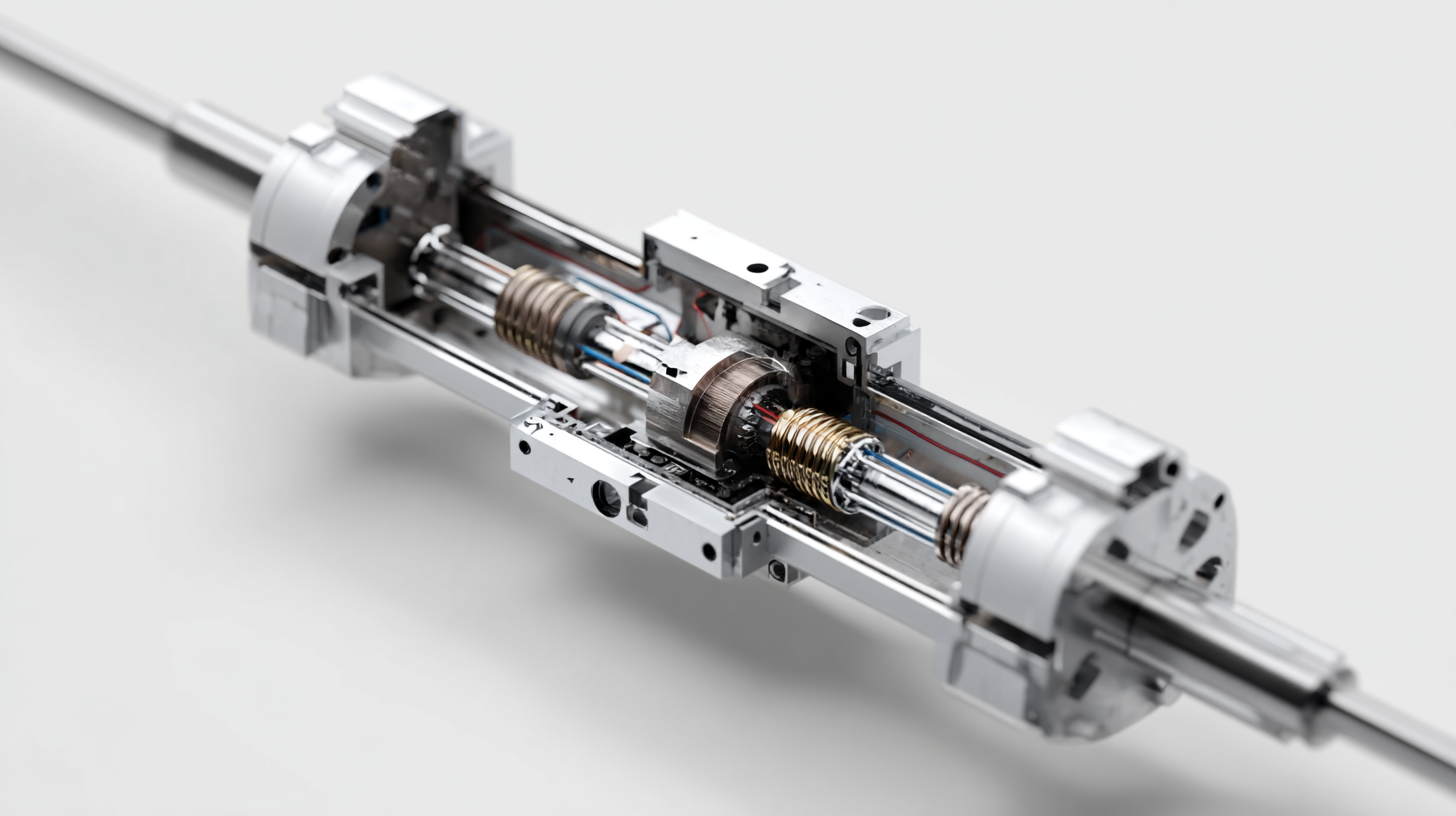

Another compelling advantage of worm drives is their inherent self-locking capability. This feature ensures that the system remains stationary when not in operation, preventing backdrive and enhancing safety in applications like robotics and automated machinery. This self-locking behavior is particularly valuable in scenarios where maintaining a specific position is critical, providing peace of mind to engineers and operators alike. Furthermore, the compact design of worm drive systems allows for integration into tight spaces, making them ideal for modern compact machinery.

5 Essential Tips for Implementing Worm Drive Systems in Your Projects

When integrating worm drive mechanisms into your mechanical projects, understanding their unique characteristics and operational benefits is paramount. Worm drives are favored for their high gear reduction ratios, which can exceed 100:1 in some cases, creating significant torque with minimal space requirements. According to a report by the American Gear Manufacturers Association, worm gears can achieve transmission efficiencies of up to 80%, making them an invaluable component in applications where compact design and efficiency are critical.

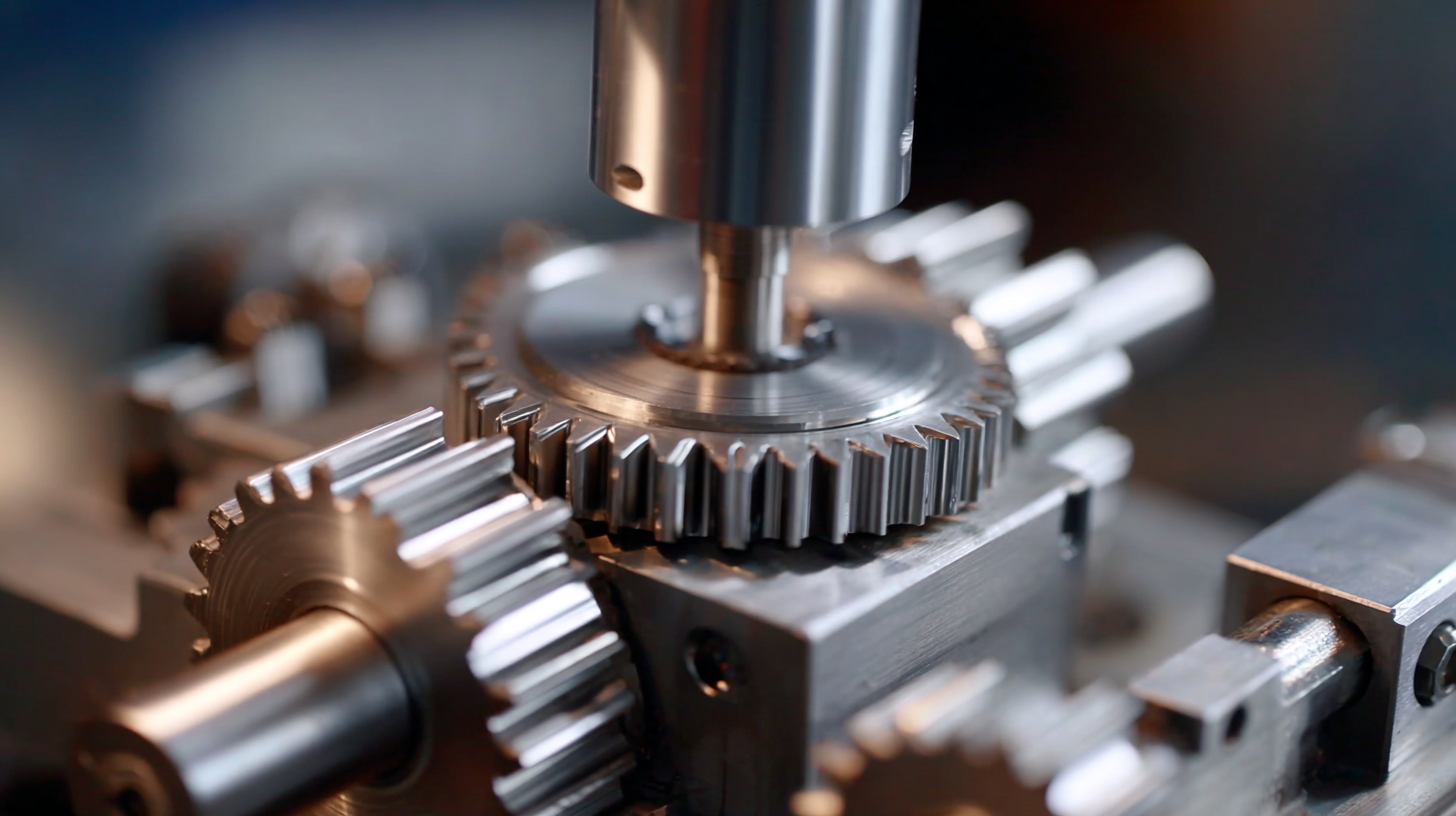

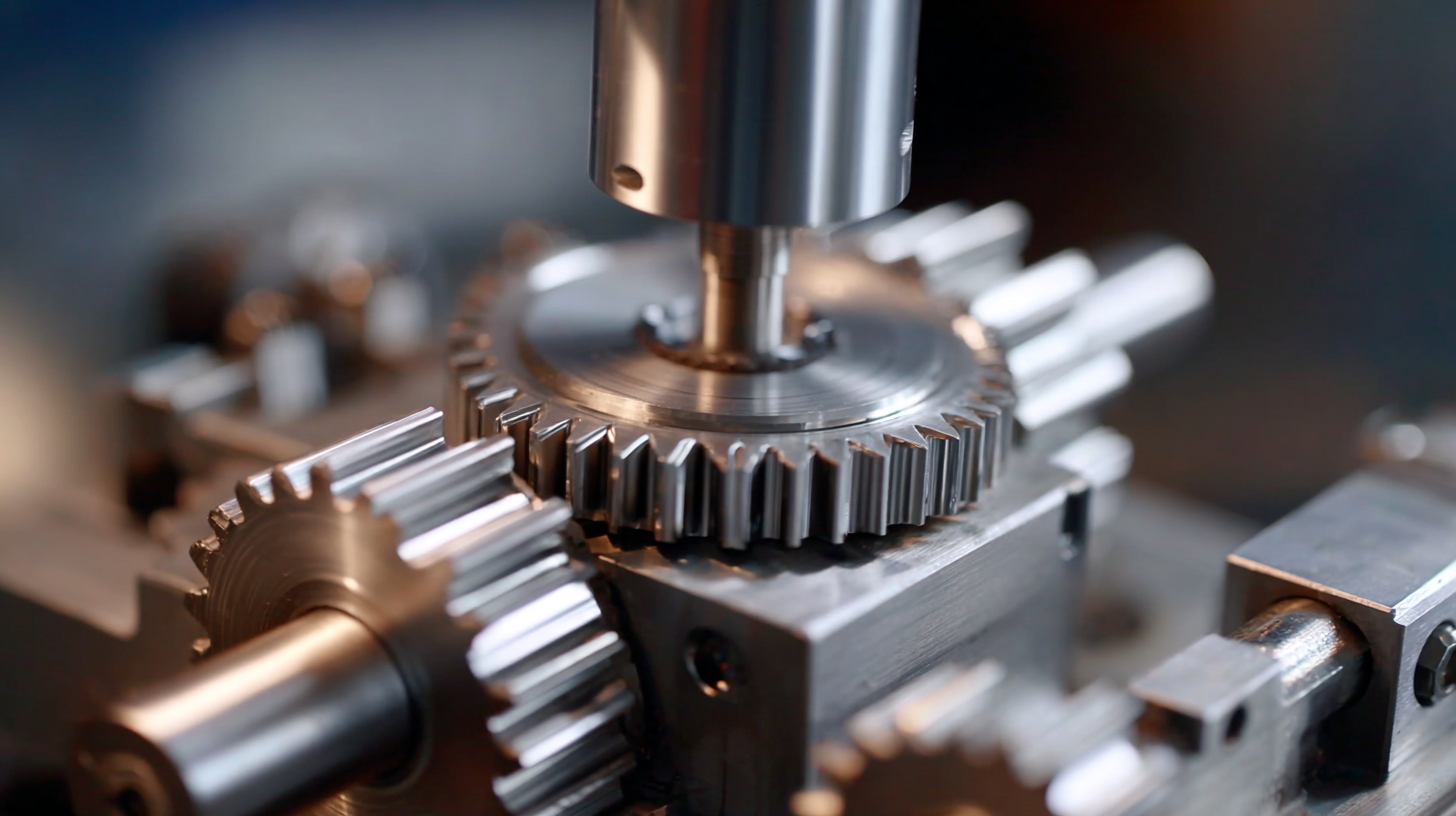

Tip: Ensure precise alignment during installation. Misalignment can lead to excessive wear and reduced efficiency. Utilizing precision machining equipment will help maintain the necessary tolerances.

Moreover, material selection plays a crucial role in the performance of worm drive systems. Reports indicate that using bronze worms paired with steel gears enhances durability and reduces the risk of galling. Implementing heat treatment processes can also significantly improve the lifespan of the drive.

Tip: Adjust the lubrication system according to the operational environment. Proper lubrication minimizes friction and heat, optimizing the system's overall performance. Regular maintenance checks on lubricant levels can prolong the drive's functionality.

How to Troubleshoot Common Issues with Worm Drive Mechanisms

Worm drive mechanisms are invaluable in various mechanical applications, offering high torque with minimal backlash. However, like any mechanical system, they can encounter issues that require troubleshooting. One common problem is excessive wear on the worm and worm gear, which can lead to inefficient transmission and failure. Regular inspection of these components is essential to identify wear early and prevent operational downtime.

Tip: To extend the lifespan of your worm drive, ensure proper lubrication is applied. The right lubricant reduces friction and helps dissipate heat, making it crucial for maintaining optimal performance.

Another frequent issue involves misalignment, where the worm and gear do not mesh properly. Misalignment can cause increased noise, vibration, and operational failures. Adjusting the mounting position and ensuring proper alignment during installation can greatly reduce these issues.

Tip: Utilize alignment tools or laser alignment systems to achieve precise positioning, ensuring that the worm and gear are correctly aligned for smooth operation and longevity.

By addressing these common issues proactively, you can maintain the efficiency and reliability of your worm drive mechanisms in your mechanical projects.