Exploring the Mechanics of Worm Drive: The Unsung Hero of Gear Systems in Modern Engineering

Worm drives are often overshadowed by more conventional gear systems, yet they play a critical role in modern engineering applications, providing unique advantages in terms of torque transmission and space efficiency. According to a report by MarketsandMarkets, the global gear market is expected to reach $235.6 billion by 2026, with worm drives representing a significant portion of this growth due to their effectiveness in high-load applications and their ability to achieve high gear ratios in a compact form factor. With advantages such as low backlash and smooth operation, worm drives are particularly favored in industries ranging from robotics to Automotive. As engineers continue to seek innovative solutions to enhance machinery performance, the importance of understanding and optimizing worm drive systems cannot be overstated, making them the unsung heroes of gear systems.

Understanding the Basic Principles of Worm Drive Mechanisms

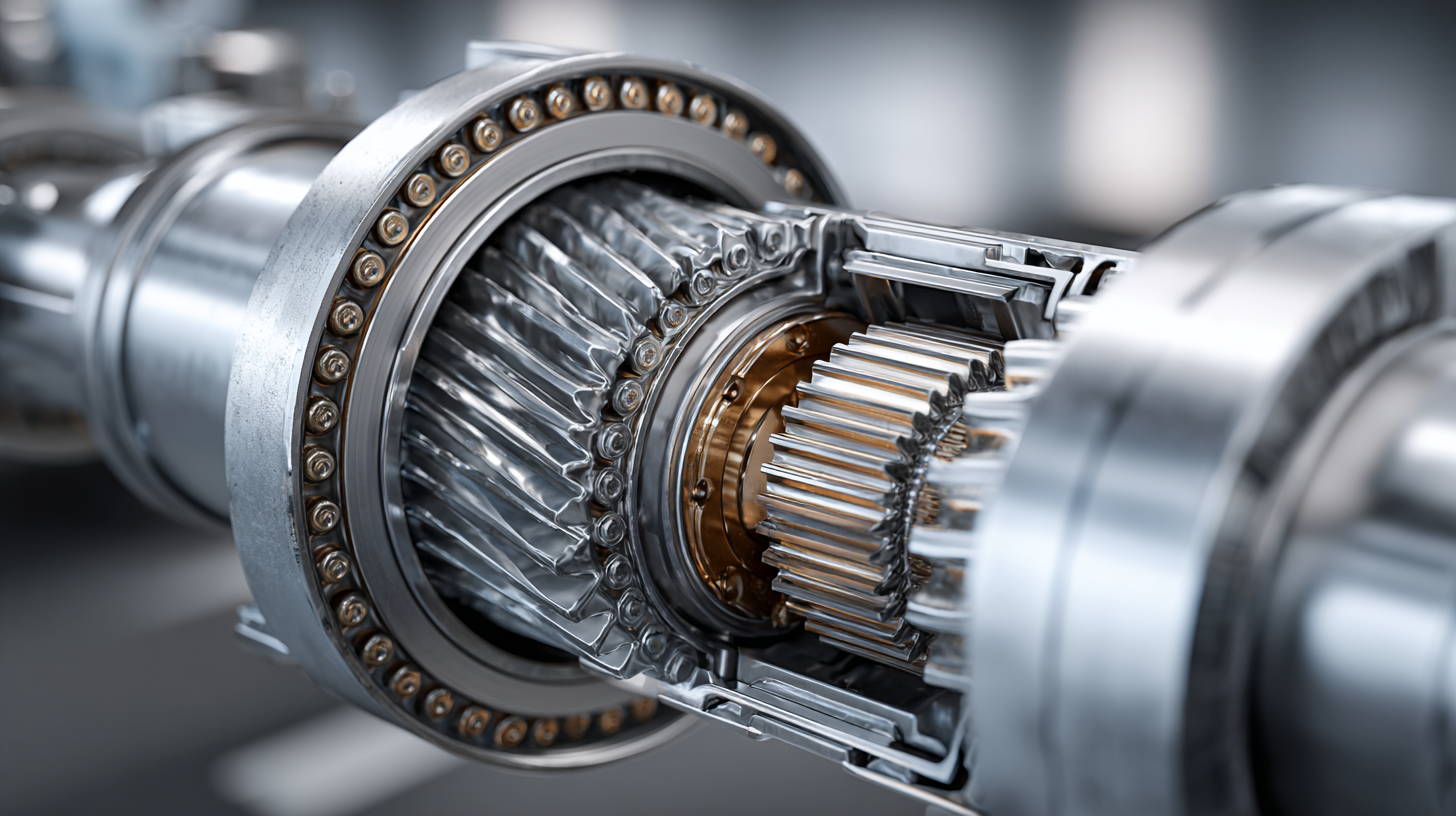

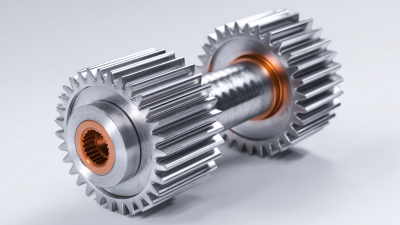

Worm drive mechanisms are a remarkable and often overlooked component in modern engineering, providing unique advantages in gear systems. At their core, a worm drive consists of a worm, which resembles a screw, and a worm wheel, which is a gear in contact with the worm. This configuration enables a significant gear reduction in a compact space. The primary advantage of worm drives lies in their ability to transmit power efficiently while allowing for a high reduction ratio, making them suitable for applications requiring precise motion control and high torque.

The operation of a worm drive is based on the principles of sliding friction and mechanical advantage. When the worm rotates, it engages with the worm wheel, converting rotational motion into linear motion. The unique geometry of the worm allows for self-locking capabilities, meaning that the driven component cannot easily move back, which is particularly beneficial in applications like elevators or conveyor systems. Additionally, the smooth operation of worm drives reduces wear and noise, offering a quieter alternative that is essential in many industrial applications. Understanding these basic principles showcases the essential role worm drives play in the efficiency and effectiveness of gear systems.

Exploring the Mechanics of Worm Drive: The Unsung Hero of Gear Systems in Modern Engineering

| Parameter |

Description |

Value |

| Efficiency |

Typical efficiency of worm drives |

40% - 90% |

| Speed Ratio |

Ratio between input and output speeds |

1:5 to 1:100 |

| Load Capacity |

Maximum load without failure |

Up to several tons |

| Angle of Engagement |

Effective input angle in worm drives |

20° - 30° |

| Material |

Common materials used for worm drive components |

Bronze, Steel, Plastic |

| Applications |

Common uses of worm drives in engineering |

Conveyor systems, Elevators, Automotive industry |

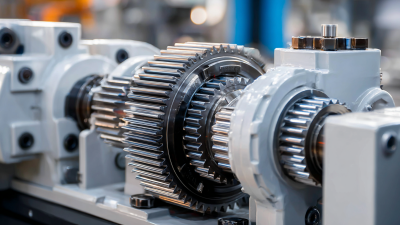

Key Advantages of Worm Drives in Engineering Applications

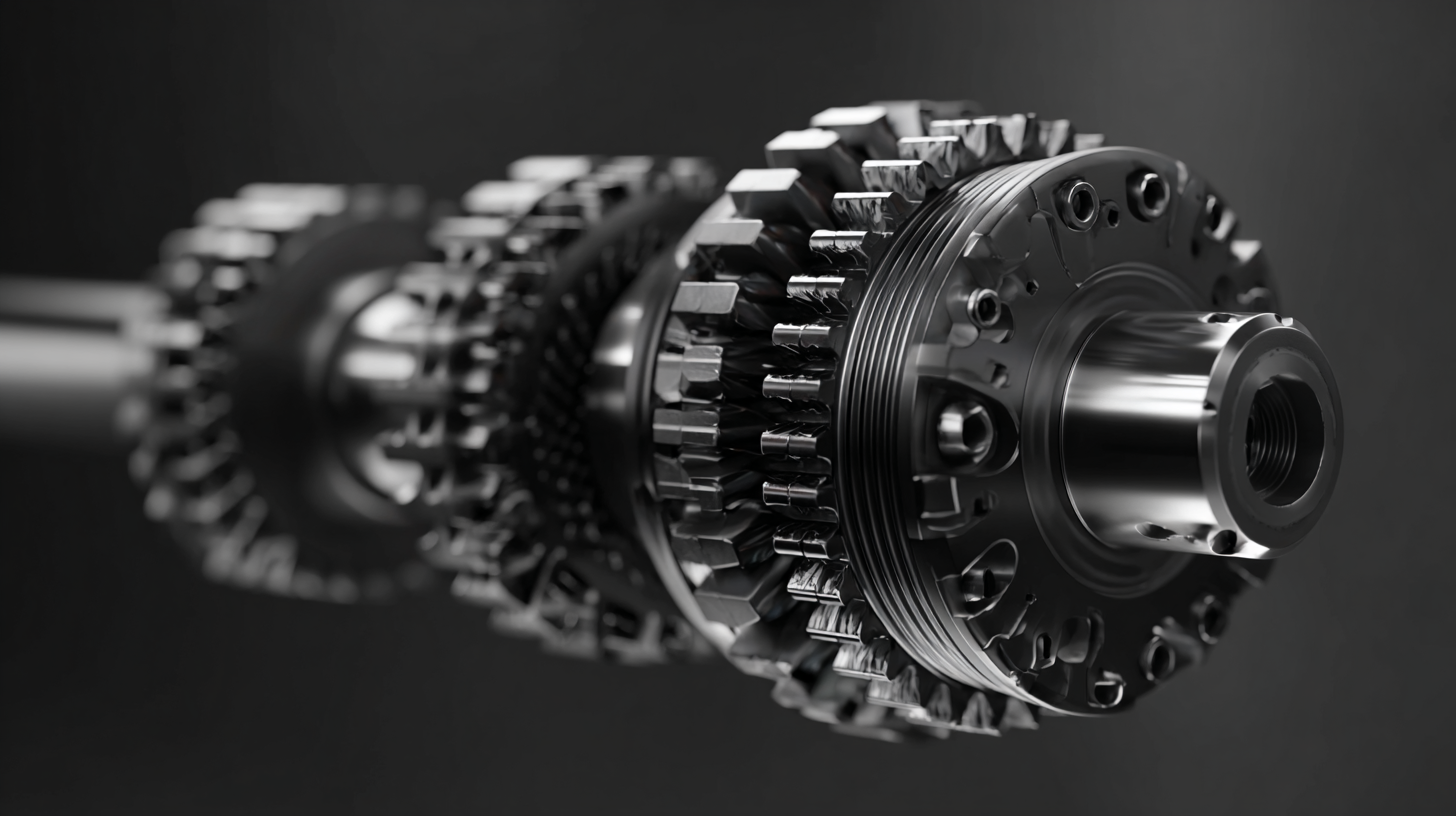

Worm drives are an often-overlooked component in modern engineering that offer unique advantages crucial for a range of applications. One of the key benefits of worm drives is their ability to provide high torque output in a compact form. This is particularly advantageous in environments where space is limited, allowing for efficient power transmission without the need for extensive redesign. Additionally, the self-locking nature of worm drives prevents back-driving, ensuring stability and safety in machinery that requires precise control.

Worm drives are an often-overlooked component in modern engineering that offer unique advantages crucial for a range of applications. One of the key benefits of worm drives is their ability to provide high torque output in a compact form. This is particularly advantageous in environments where space is limited, allowing for efficient power transmission without the need for extensive redesign. Additionally, the self-locking nature of worm drives prevents back-driving, ensuring stability and safety in machinery that requires precise control.

Another significant advantage of worm drives is their capability to reduce the speed of the input gear while increasing torque. This feature is especially beneficial in applications such as conveyor systems and elevators, where controlled motion is vital. The design and construction of worm drives also allow for quieter operation compared to other gear systems, making them suitable for use in settings that demand minimal noise disruption. Overall, the unique mechanics of worm drives not only enhance efficiency in engineering systems but also contribute to overall machinery longevity.

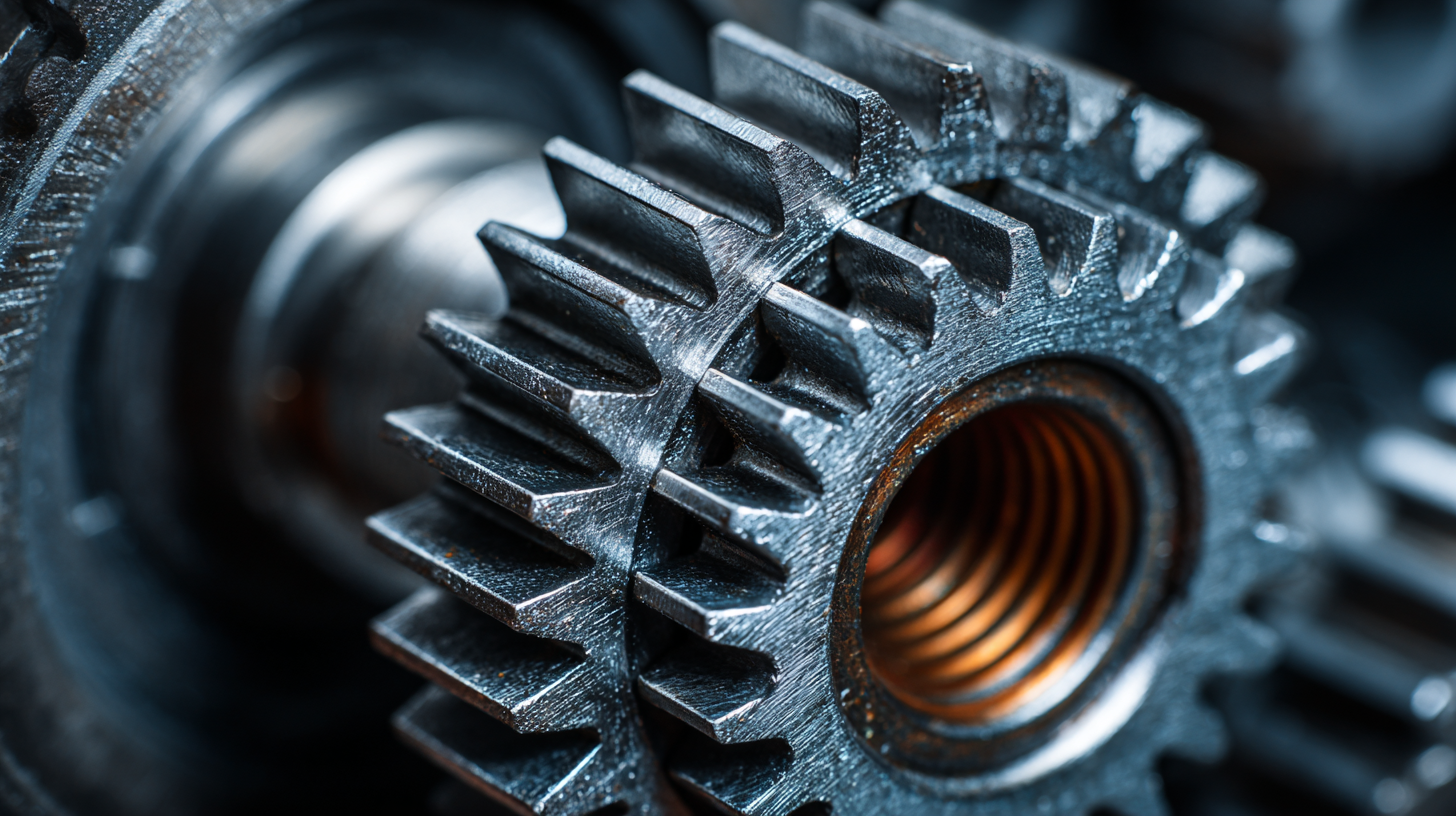

Challenges and Limitations of Worm Drive Systems

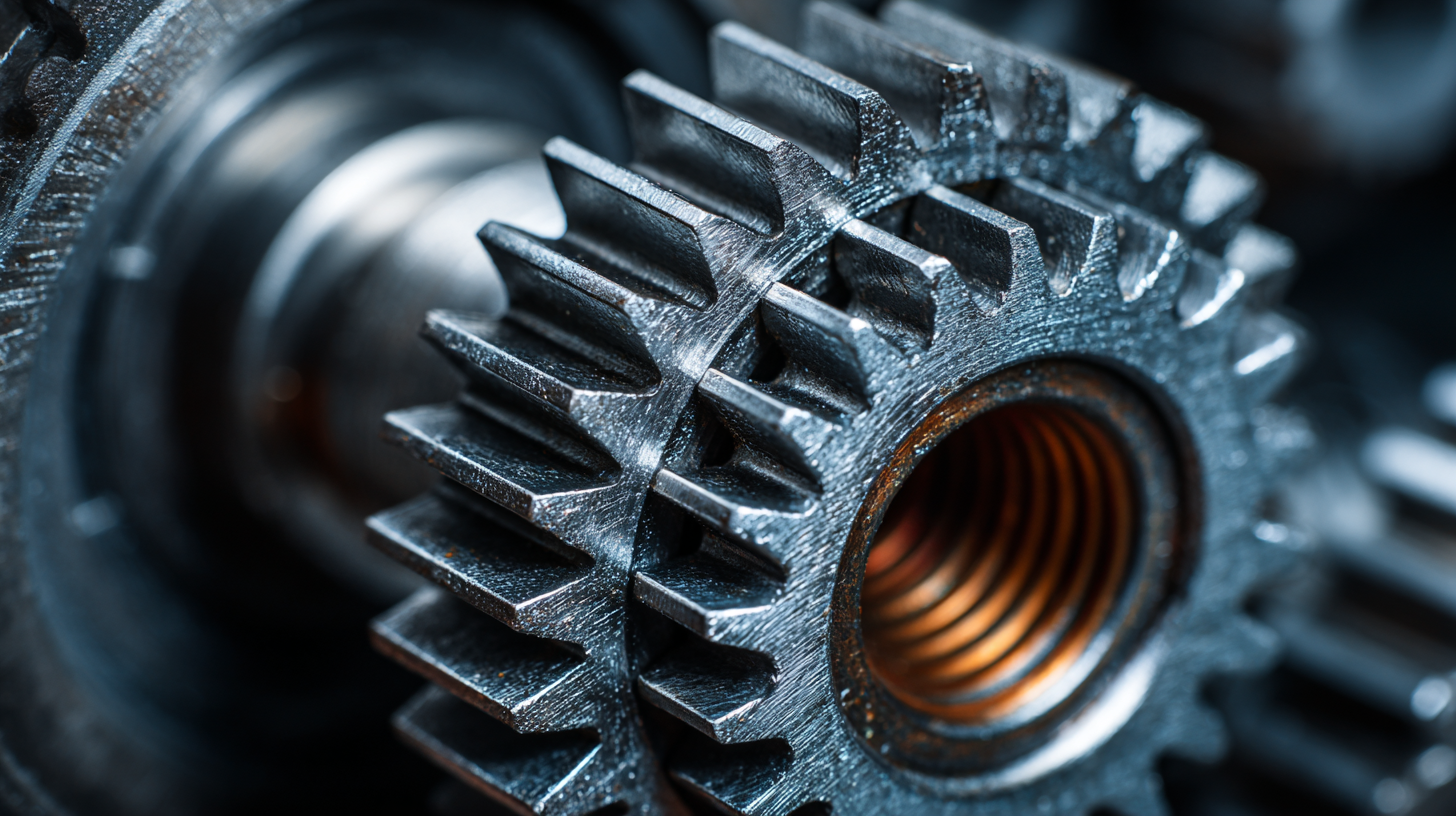

Worm drive systems are often hailed for their compact design and high torque transmission capabilities, yet they face several challenges that limit their widespread application in modern engineering. One significant limitation is their efficiency; according to a report by the American Gear Manufacturers Association (AGMA), worm gears typically exhibit efficiencies ranging from 30% to 90%, largely dependent on the lead angle and material used. This efficiency drop is primarily caused by the sliding contact between the worm and the gear, leading to increased friction and heat, which can further degrade performance over time.

Worm drive systems are often hailed for their compact design and high torque transmission capabilities, yet they face several challenges that limit their widespread application in modern engineering. One significant limitation is their efficiency; according to a report by the American Gear Manufacturers Association (AGMA), worm gears typically exhibit efficiencies ranging from 30% to 90%, largely dependent on the lead angle and material used. This efficiency drop is primarily caused by the sliding contact between the worm and the gear, leading to increased friction and heat, which can further degrade performance over time.

Moreover, the load capacity of worm drives presents another challenge. While they can provide high reduction ratios, their load-carrying capabilities can be constrained by factors such as lubrication issues and thermal management. A study published in the Journal of Mechanical Engineering notes that nearly 75% of worm gear failures can be attributed to poor lubrication practices, underscoring the importance of maintaining optimal operating conditions. Additionally, the material selection plays a crucial role; using materials with insufficient hardness can lead to excessive wear and eventual failure, further limiting the application of worm drives in demanding environments.

As engineers continue to innovate, addressing these limitations will be critical for enhancing the reliability and efficiency of worm drive systems in the future.

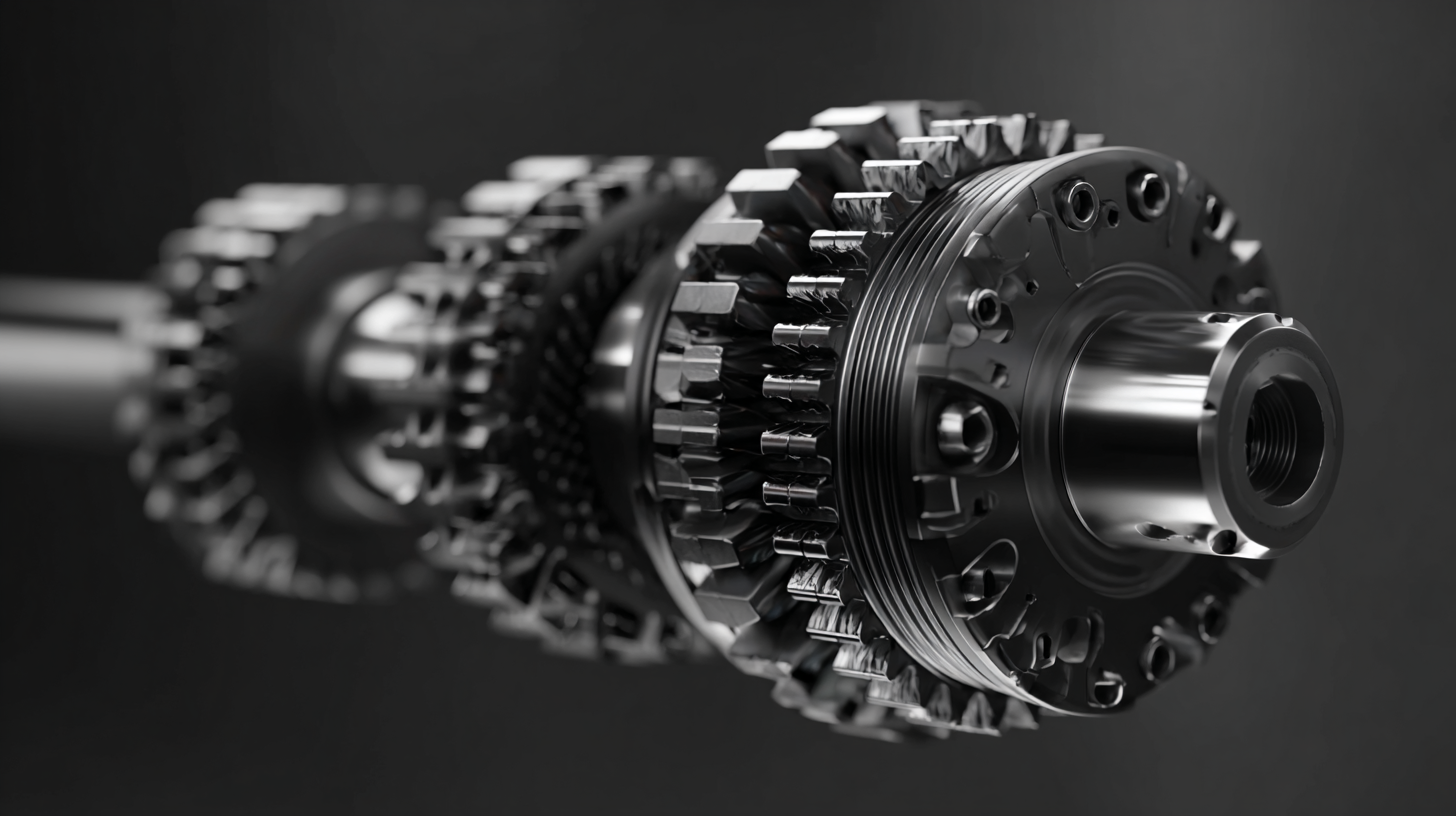

Innovative Developments and Future Trends in Worm Drive Technology

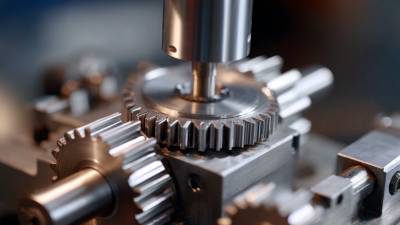

In recent years, worm drive technology has garnered renewed attention as innovative developments continue to reshape its applications across various industries. Advances in materials and manufacturing processes have led to the production of lighter, stronger, and more efficient worm drive systems. For instance, the global worm gear market is anticipated to grow at a compound annual growth rate (CAGR) of 5.1% from 2021 to 2026, highlighting the escalating demand for enhanced performance in power transmission solutions.

Moreover, the integration of smart technologies in worm drive systems has further improved their efficiency and reliability. Industry reports indicate that the adoption of IoT (Internet of Things) and advanced sensors within worm drive assemblies can yield maintenance cost reductions of up to 30%. These smart systems not only provide real-time data on performance parameters but also facilitate predictive maintenance, which is crucial to minimizing downtime in high-stakes environments such as renewable energy and robotics. As innovations continue to unfold, worm drives are set to play a pivotal role in the evolution of gear technology, ensuring a sustainable future for engineering applications across the globe.

Comparative Analysis: Worm Drives vs. Other Gear Systems

Worm drives are often overlooked in gear systems, yet they hold a significant advantage over other types of drive systems, particularly in applications requiring high reduction ratios and compact design. According to a report by the American Gear Manufacturers Association (AGMA), worm gear systems can achieve reduction ratios of up to 100:1 or more, enabling substantial torque multiplication in limited space. This efficiency makes them ideal for applications such as conveyors and lifting devices, where both space and power density are critical.

When compared to more traditional gear systems, such as spur or helical gears, worm drives stand out in terms of their ability to offer non-backdrivable characteristics. The inherent design of a worm drive creates a one-way motion, making it particularly suitable for applications where the load must not fall back without power. A study from the International Journal of Engineering Research observed that this feature enhances safety in industrial machinery, providing peace of mind in situations involving heavy loads. Moreover, while worm drives may present lower efficiency than some other systems—typically around 50-90%—their unique advantages in space constraint and load handling often outweigh these drawbacks, demonstrating their vital role in modern engineering solutions.

Comparative Analysis of Gear Systems: Worm Drives vs. Other Gear Systems

This chart presents a comparative analysis of the efficiency of different gear systems, highlighting the performance of worm drives alongside spur gears, bevel gears, planetary gears, and rack and pinion mechanisms. The data indicates that while worm drives are effective, there are other gear systems with higher efficiency ratings.