What is a Worm Gear Reducer? Understanding Its Functionality and Applications

Worm gear reducers are essential components in the realm of mechanical engineering, known for their unique ability to provide high torque output in a compact size. According to a recent market report by Allied Market Research, the global worm gear market is expected to reach $3.93 billion by 2027, growing at a CAGR of 5.4% from 2020. This growth is largely driven by the increasing demand for automation across various industries, including manufacturing, automotive, and construction, where efficiency and reliability are paramount.

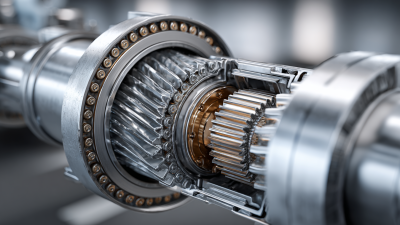

The functionality of a worm gear reducer is based on the meshing of a worm screw with a worm wheel, resulting in a higher output torque and a reduction in speed. This mechanism allows it to be used in a wide array of applications, ranging from conveyor systems to robotics. As industries strive for greater efficiency, the adoption of worm gear reducers is becoming increasingly common, with a market trend showing a shift towards more specialized designs that enhance performance while minimizing energy consumption. Such advancements ensure that worm gear reducers remain a vital part of modern machinery and a solid choice for engineers seeking reliable solutions in power transmission.

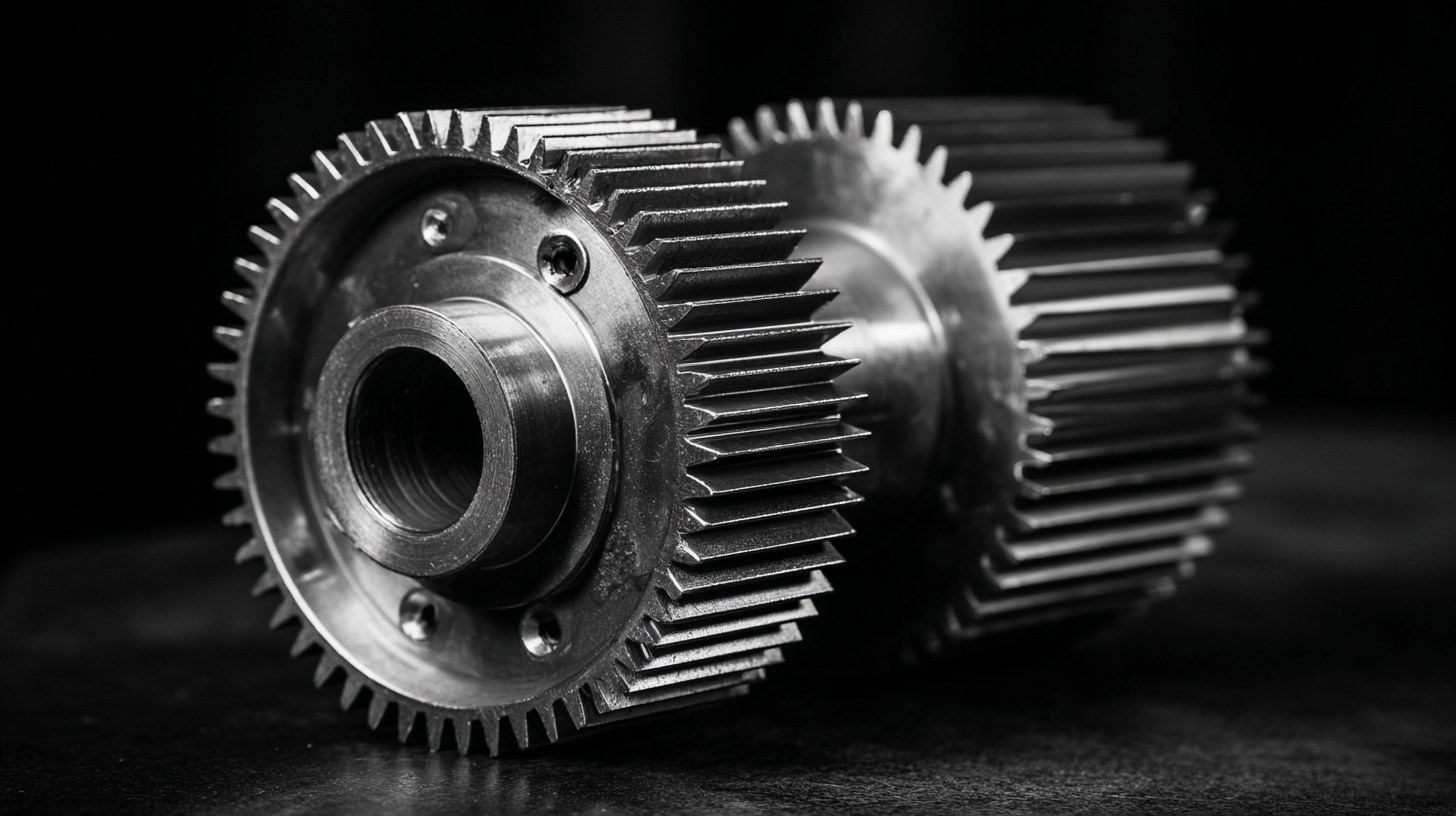

Characteristics of Worm Gear Reducers: Design and Mechanical Advantages

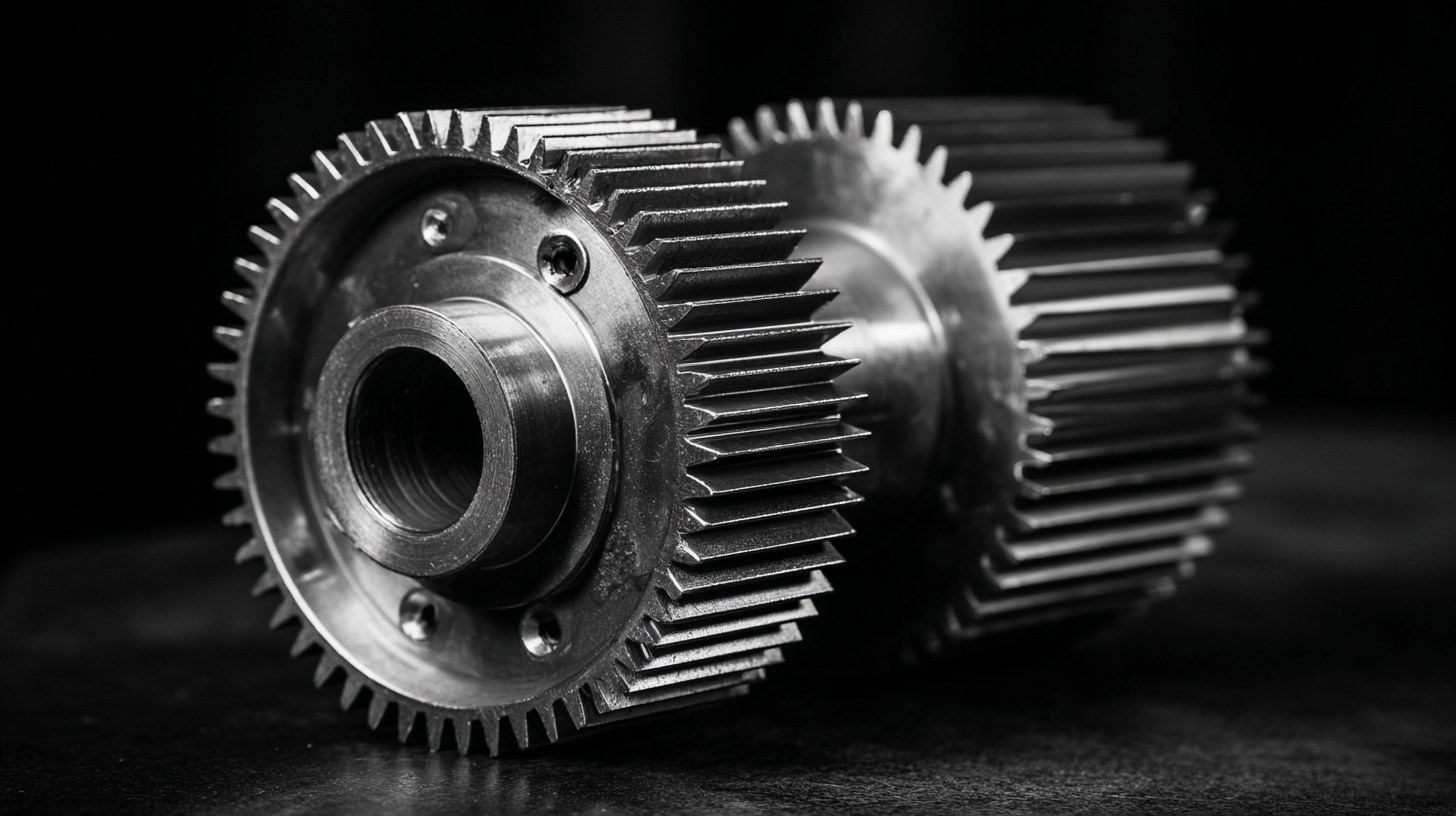

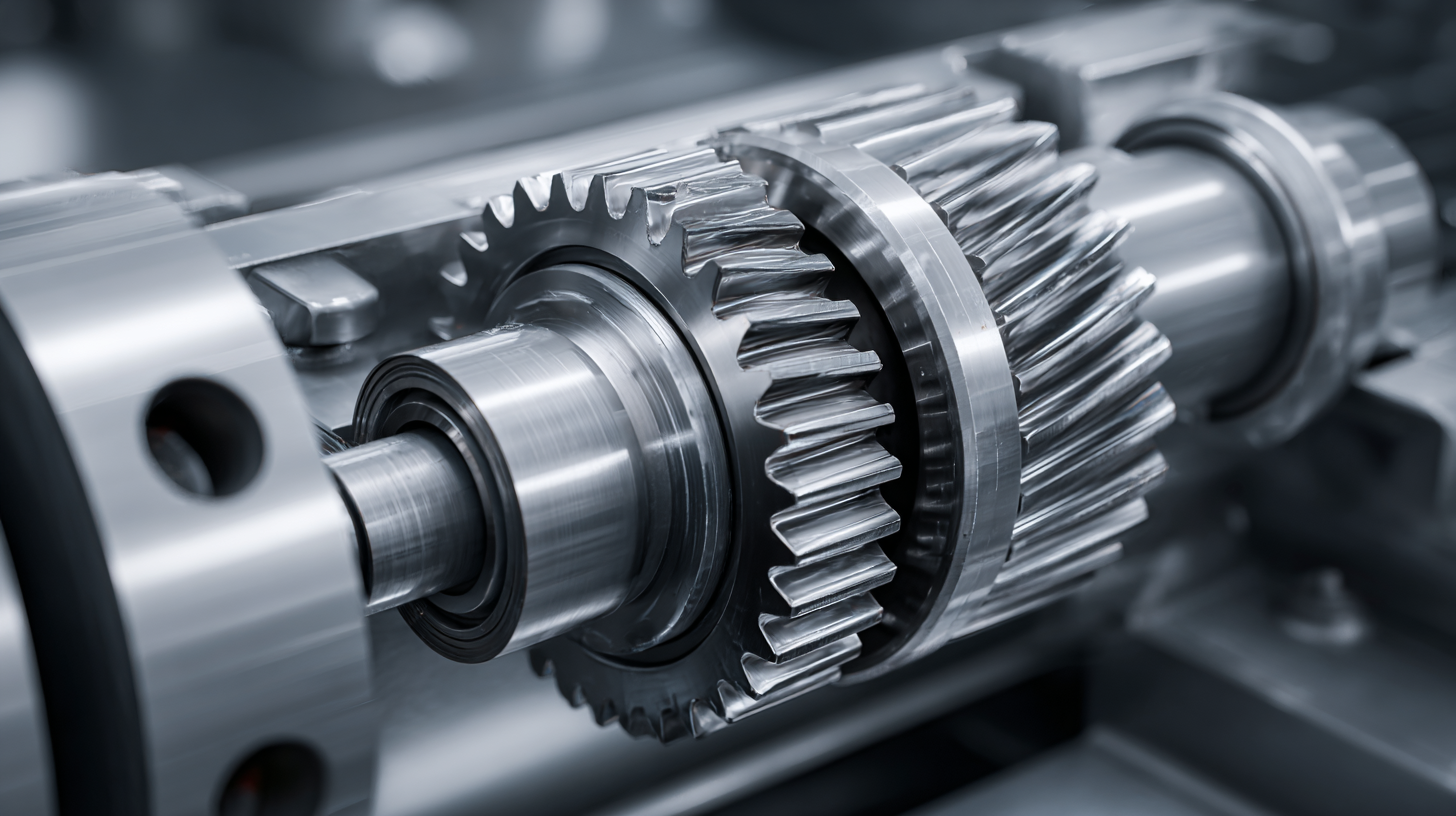

Worm gear reducers are essential components in various machinery, renowned for their unique design and mechanical advantages. The distinct feature of worm gears involves a screw-like worm that meshes with a gear, allowing for significant speed reduction while increasing torque. This design results in a compact system that provides high gear ratios, making it ideal for applications where space is limited but torque is crucial, such as in robotics or heavy machinery.

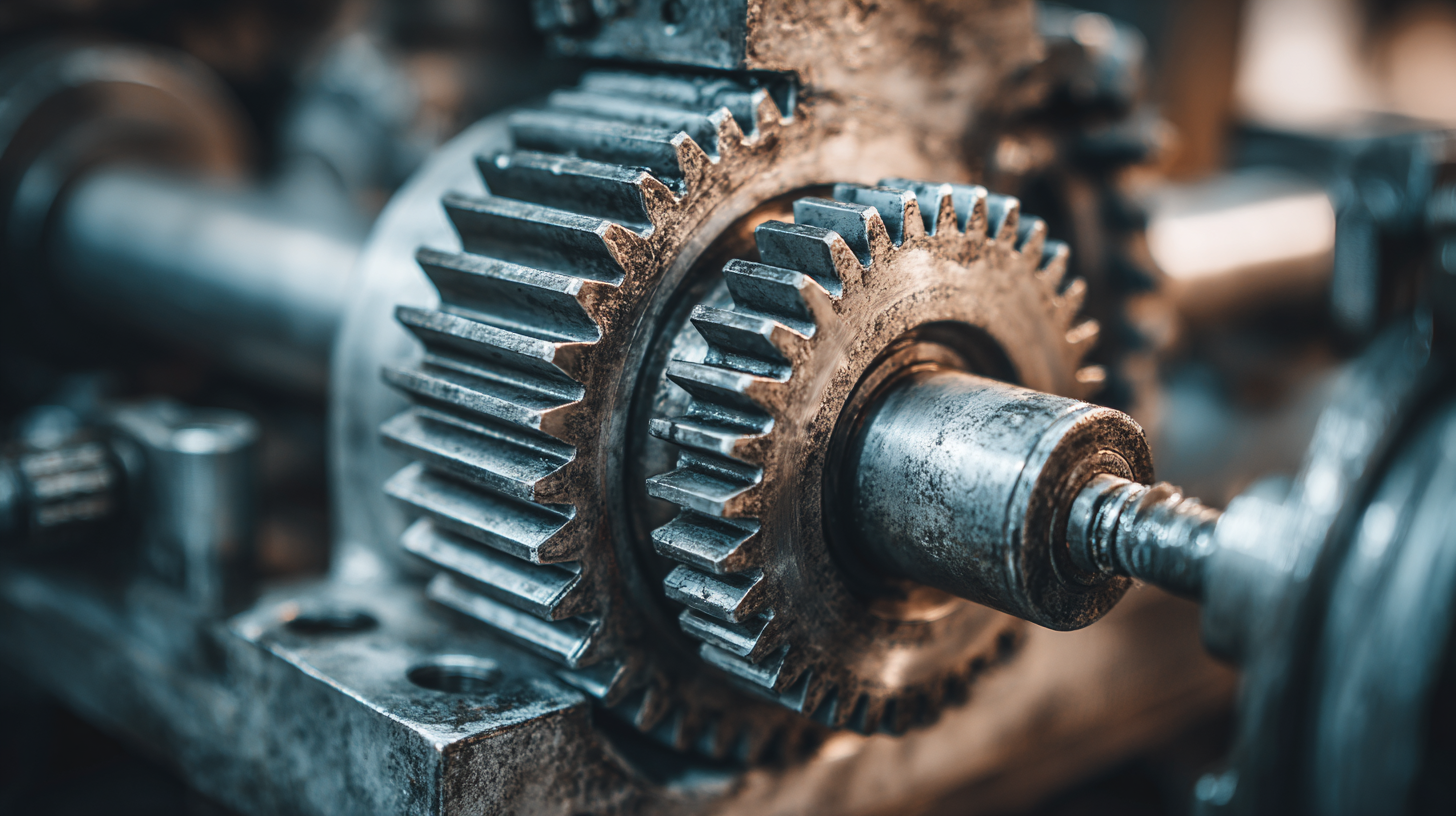

Tips: When selecting a worm gear reducer, consider the load requirements and the environment in which it will operate. Ensuring proper lubrication and maintenance routines can greatly enhance the lifespan and efficiency of the reducer. In addition, the choice of materials used in the construction can impact durability and performance, so it is essential to consult with manufacturers about optimal options for specific applications.

Another advantage of worm gear reducers lies in their inherent self-locking property, which prevents back-driving. This is particularly valuable in applications where safety and stability are paramount. Understanding these characteristics can help engineers and designers make informed decisions to optimize their designs, whether in robotics, automotive, or other engineering fields.

Characteristics of Worm Gear Reducers: Design and Mechanical Advantages

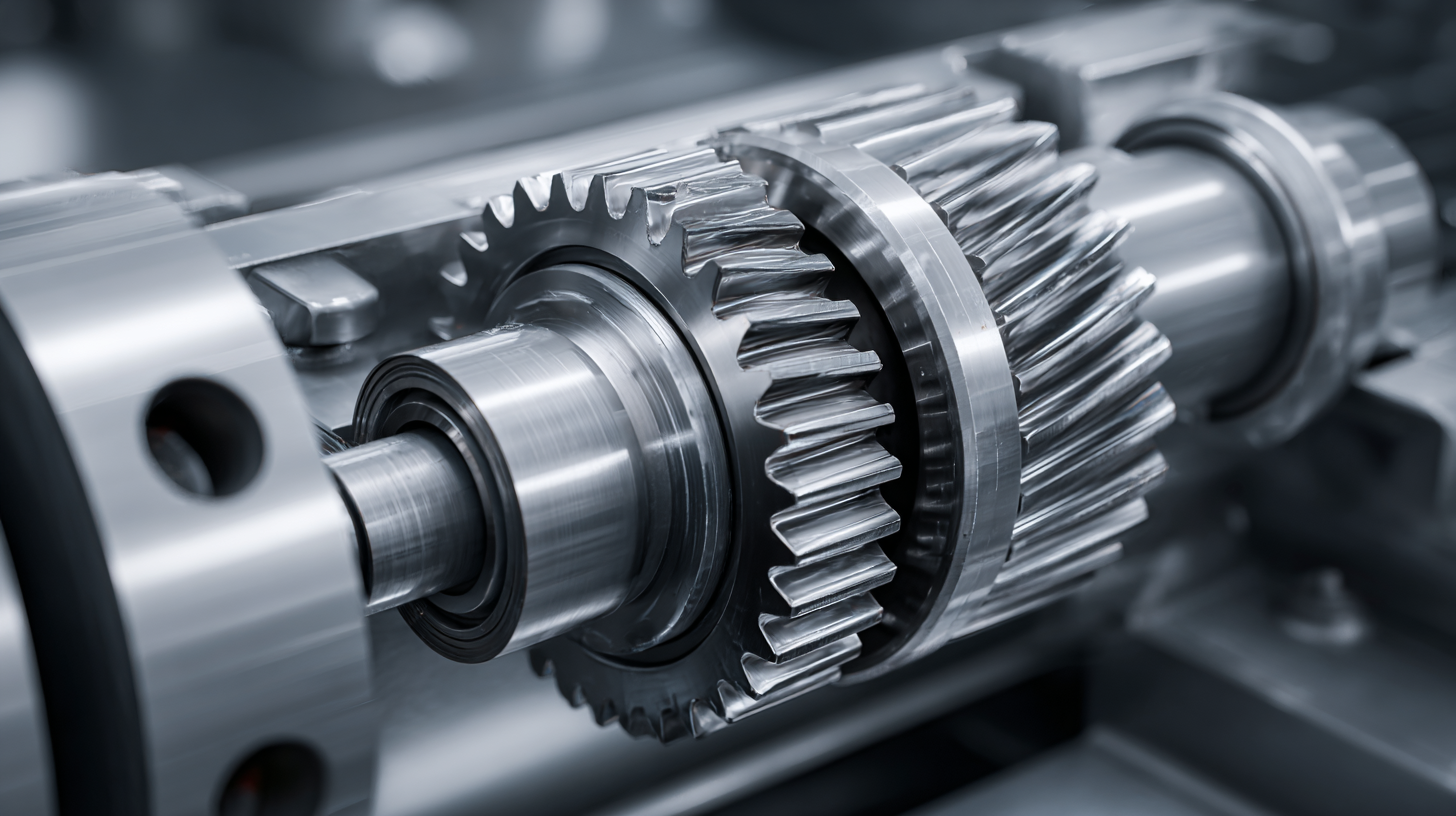

Key Functions of Worm Gear Reducers in Motion Control and Force Reduction

Worm gear reducers are crucial components in motion control systems, specifically designed to provide

speed reduction and increase

torque output. Their unique design consists

of a worm (a screw-like gear) that meshes with a worm wheel (similar to a traditional gear), allowing

for a high gear reduction in a compact form. This functionality is particularly beneficial in applications

where space is limited and power efficiency is paramount. By converting high-speed input into

lower speed output while simultaneously multiplying the torque, these reducers enable machinery to perform

optimally under varying load conditions.

In addition to speed reduction, worm gear reducers play a significant role in

force reduction, translating input force into usable

mechanical energy with reduced strain on other system components. This attribute is critical in applications

such as conveyors, elevators, and robotics, where precise control over movement and force is essential.

The self-locking feature of worm drives further enhances their utility by preventing back-driving, providing

added safety and reliability in systems that require a maintained position without continuous power supply.

Through their multifaceted roles in motion control and force management,

worm gear reducers remain an essential tool across

various industrial applications.

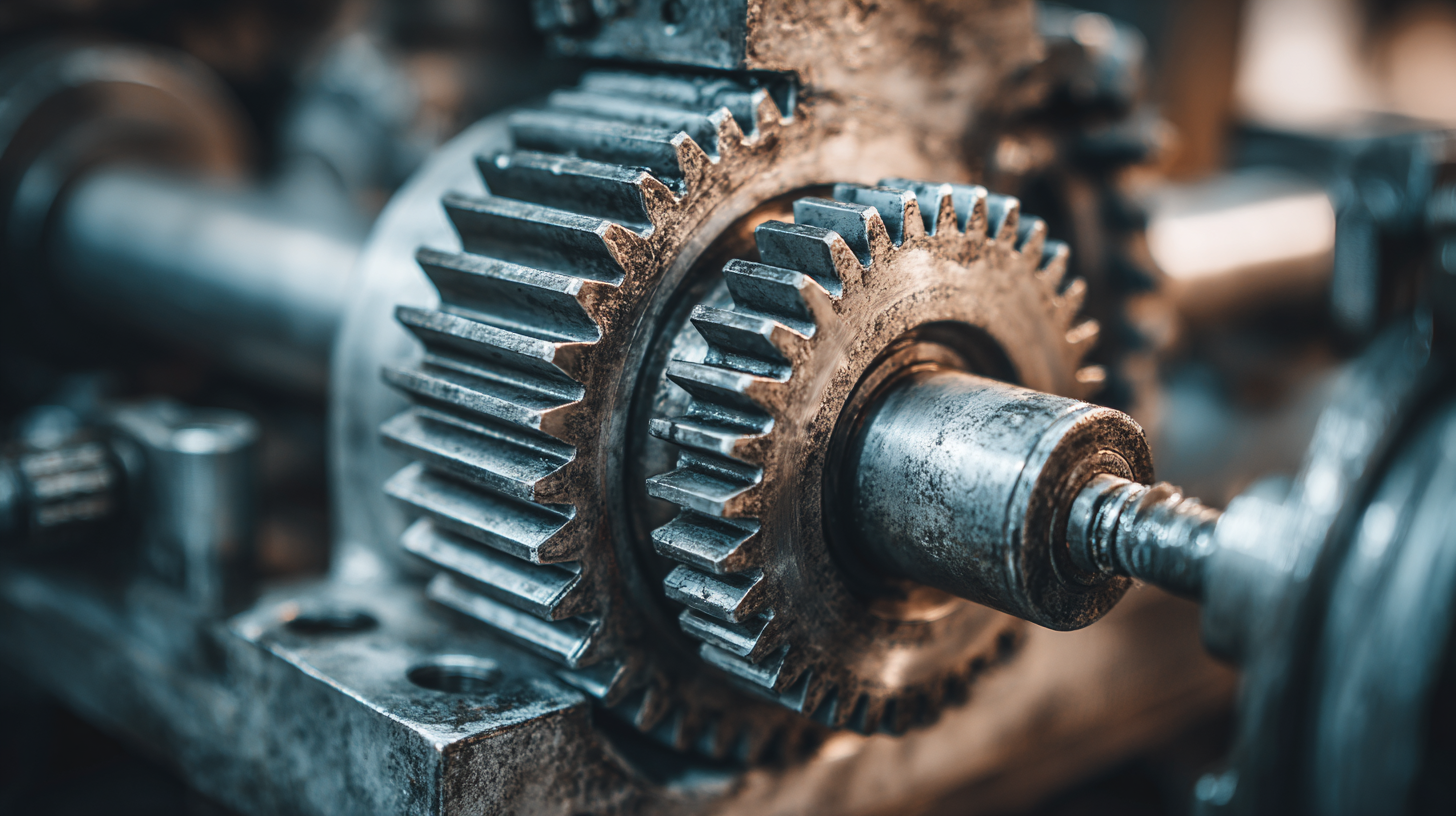

Efficiency Metrics: Analyzing Power Loss in Worm Gear Reducers

Worm gear reducers are essential components in various mechanical systems, providing high torque and efficient speed reduction. However, understanding the efficiency metrics, particularly in relation to power loss, is crucial for optimizing their performance. Power loss in worm gear reducers primarily occurs due to friction between the worm and the gear. This friction generates heat, resulting in energy dissipation that reduces overall system efficiency.

Analyzing power loss is vital for engineers seeking to enhance the design and application of worm gear reducers. By employing advanced materials and coatings, manufacturers can minimize friction and improve wear resistance. Additionally, optimizing the geometry of the worm and gear can lead to better meshing, which not only reduces power losses but also extends the lifespan of the components. Ultimately, a deep understanding of these efficiency metrics allows for more effective use of worm gear reducers in industries such as automotive, robotics, and manufacturing, leading to improved operational efficiency and reduced energy consumption.

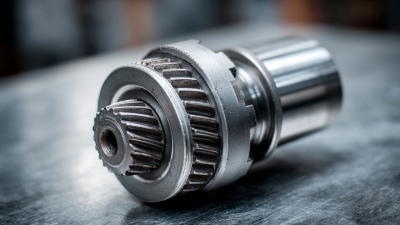

Applications Across Industries: How Worm Gear Reducers Drive Innovation

Worm gear reducers are critical components in various industries, facilitating the efficient conversion of speed and torque. Their unique design offers high reduction ratios and compact dimensions, making them ideal for applications where space is at a premium. According to a report by MarketsandMarkets, the global worm gear market is projected to reach $5.3 billion by 2025, driven by the increasing demand for automation and energy efficiency across sectors such as automotive, manufacturing, and aerospace.

Worm gear reducers are critical components in various industries, facilitating the efficient conversion of speed and torque. Their unique design offers high reduction ratios and compact dimensions, making them ideal for applications where space is at a premium. According to a report by MarketsandMarkets, the global worm gear market is projected to reach $5.3 billion by 2025, driven by the increasing demand for automation and energy efficiency across sectors such as automotive, manufacturing, and aerospace.

In the automotive industry, worm gear reducers are utilized in power steering systems and window lift mechanisms, enhancing overall vehicle performance and energy efficiency. In manufacturing, these gears support conveyors and machinery that require precise movement and positioning. The versatility of worm gear reducers is further emphasized by their application in renewable energy, particularly in wind turbines, where they contribute to optimal power generation. As industries continue to evolve towards automation and sustainability, the role of worm gear reducers will be pivotal in driving innovation and efficiency.

Market Trends and Projections for Worm Gear Reducers in 2025 and Beyond

The market for worm gear reducers is projected to experience significant growth in the coming years. According to a recent report by Market Research Future, the global worm gear reducer market is expected to reach approximately $3.2 billion by 2025, growing at a compound annual growth rate (CAGR) of around 5.6%. This growth can be attributed to the increasing demand for automation in various sectors such as manufacturing, automotive, and robotics, where efficient power transmission is essential.

Furthermore, advancements in material science and manufacturing technologies are improving the efficiency and durability of worm gear reducers, making them a preferred choice for many applications. The demand for energy-efficient systems is driving innovations in design, with manufacturers increasingly adopting lightweight materials and advanced lubrication techniques. As industries shift towards sustainable practices, worm gear reducers are likely to adapt, reinforcing their position in markets focusing on energy conservation and efficiency, which is expected to reflect in rising sales figures through 2025 and beyond.