Exploring the Advantages of Worm Gear Reducers in Modern Machinery Applications

The evolution of machinery technology continues to drive industry efficiency and innovation, particularly through the implementation of worm gear reducers. These mechanical devices play a crucial role in various modern applications, enhancing performance across sectors such as manufacturing, robotics, and automotive industries. According to a report by the Global Gear Reducer Market, the worm gear reducer segment is projected to reach USD 3.8 billion by 2025, with a compound annual growth rate (CAGR) of 5.1% from 2020 to 2025. This growth reflects the increasing demand for high-torque and compact solutions in advanced machinery systems.

Worm gear reducers are celebrated for their unique design, which allows for significant speed reduction while maintaining high torque output. They offer several advantages, including a highly efficient power transmission, self-locking capabilities, and a compact footprint that enables their integration into space-constrained applications. An analysis by the International Journal of Mechanical Engineering revealed that the efficiency of worm gear reducers can exceed 90%, making them a preferred choice in applications requiring precise motion control. As industries continue to prioritize operational efficiency and reliability, understanding the advantages of worm gear reducers becomes essential for engineers and decision-makers aiming to optimize performance in their machinery applications.

Understanding Worm Gear Reducers: A Key Component in Modern Machinery

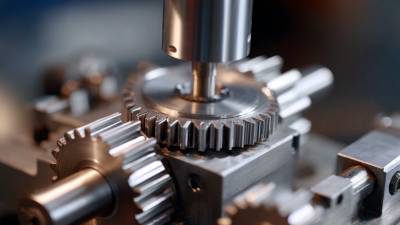

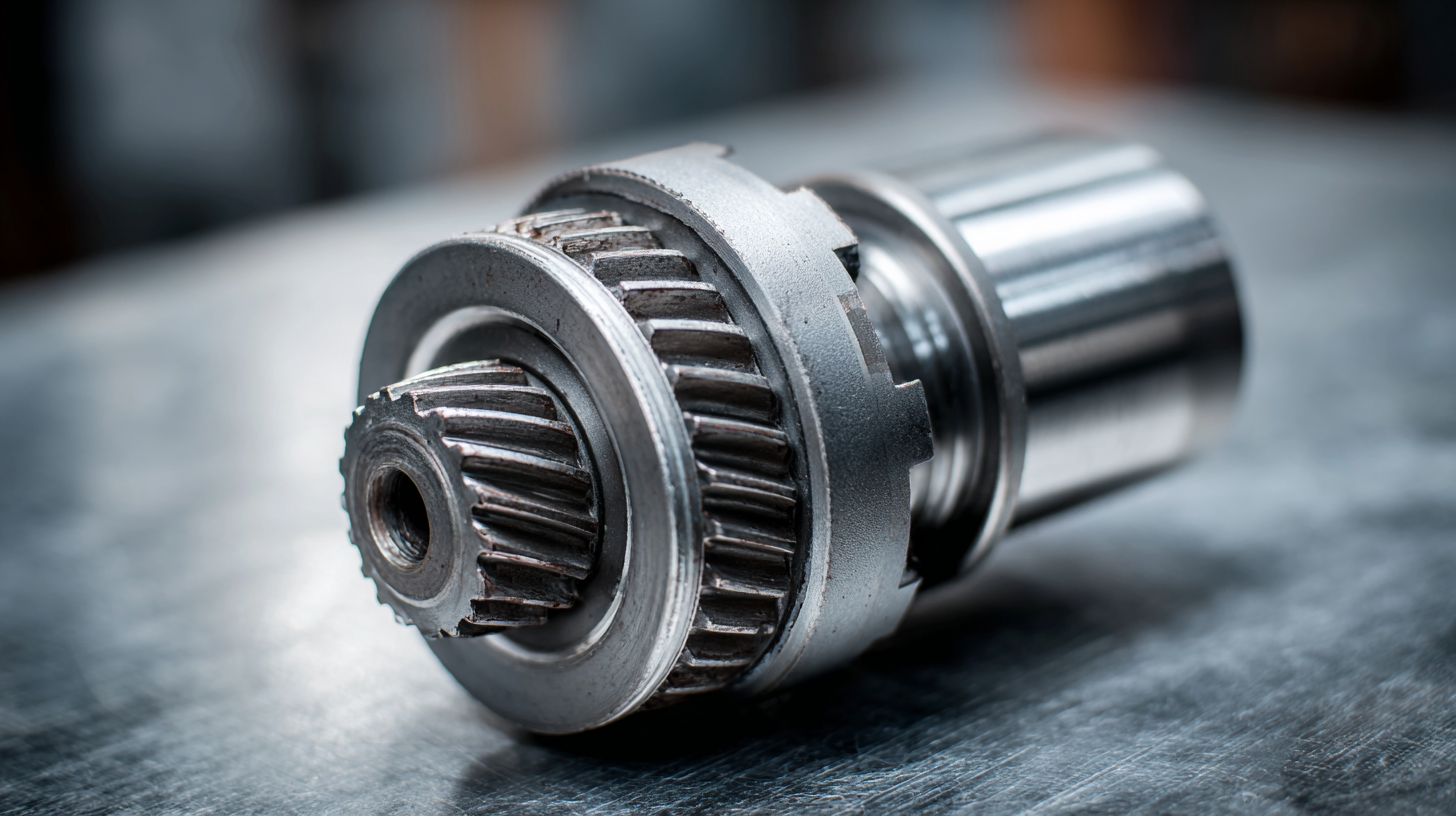

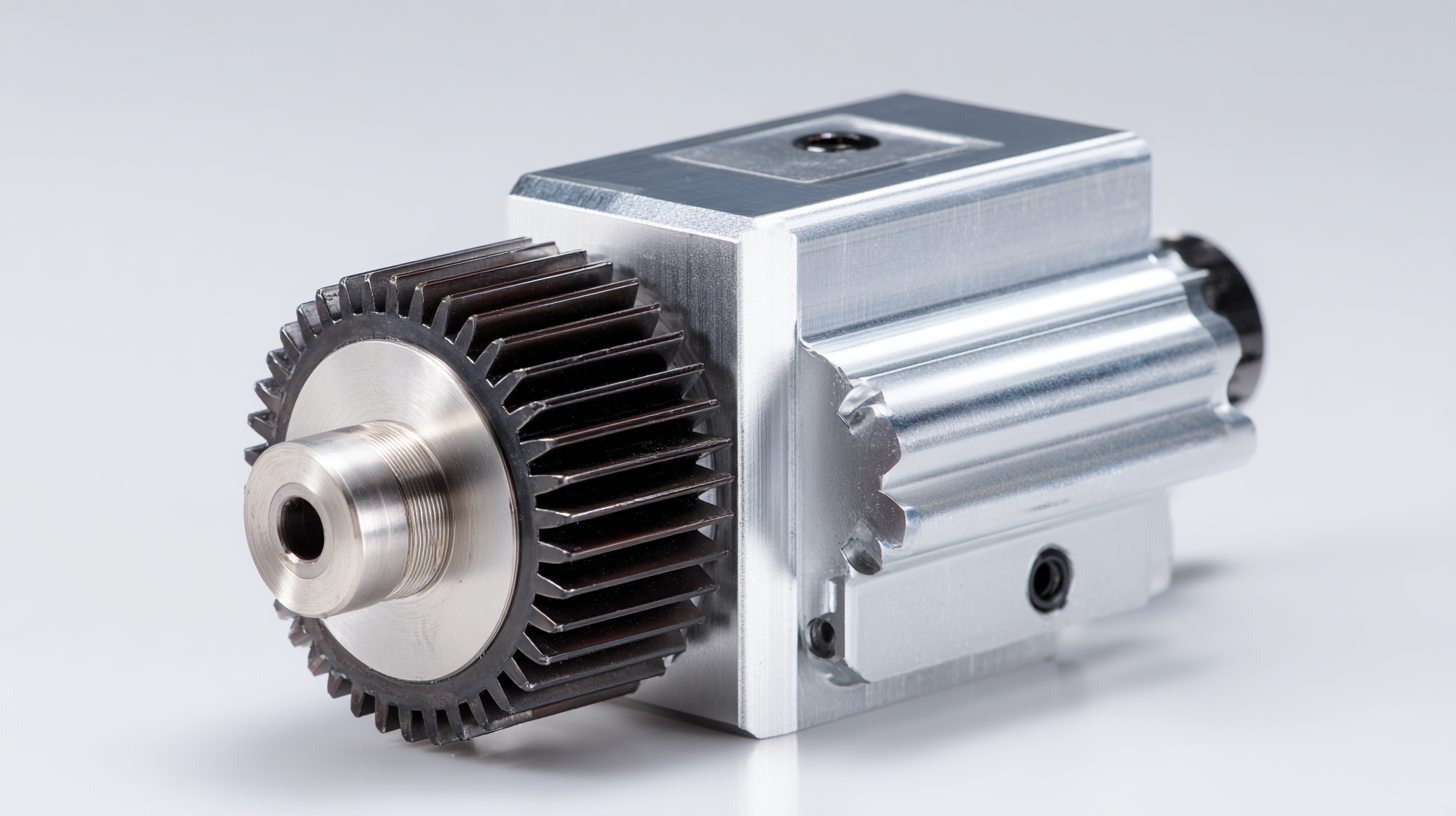

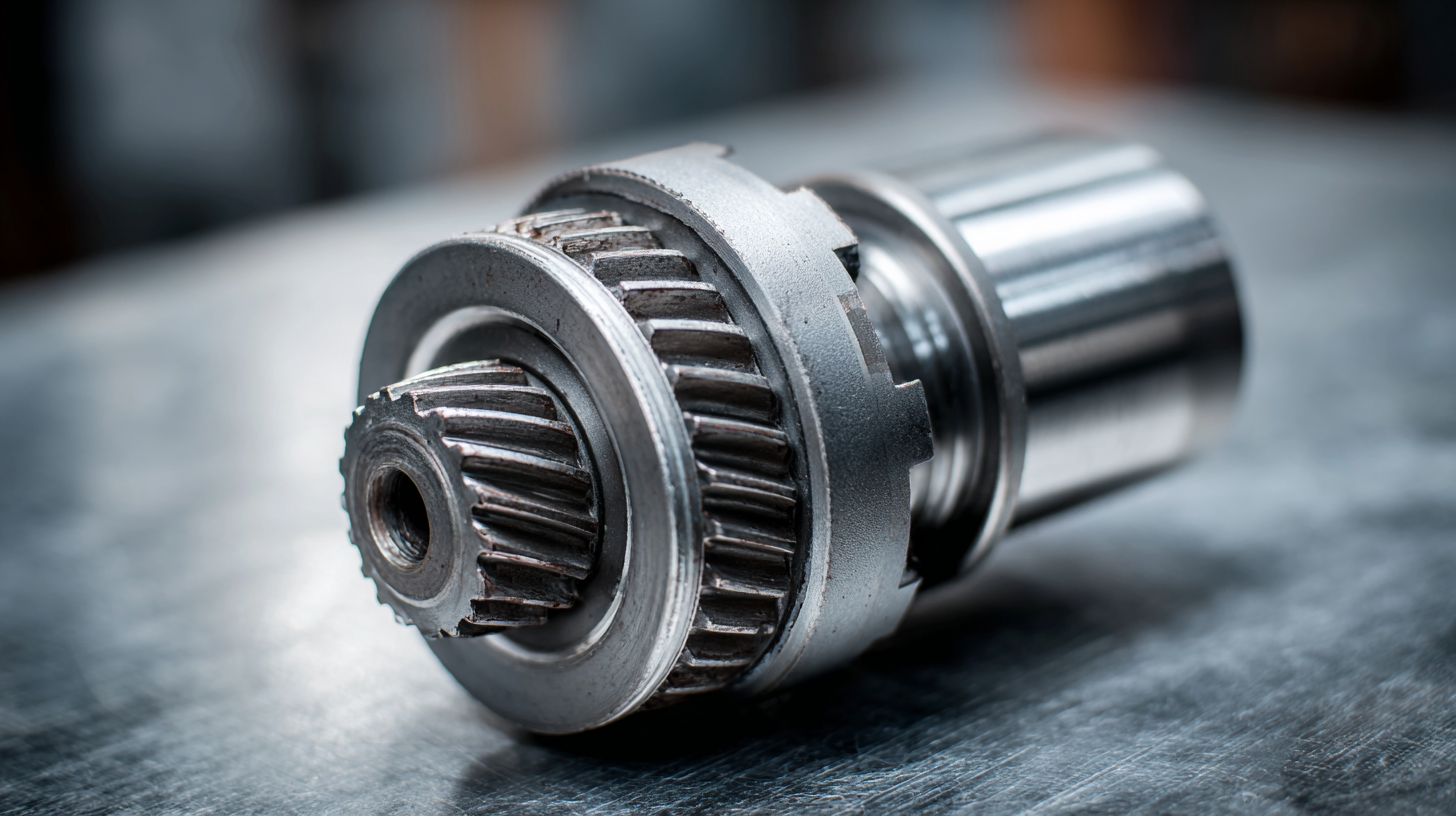

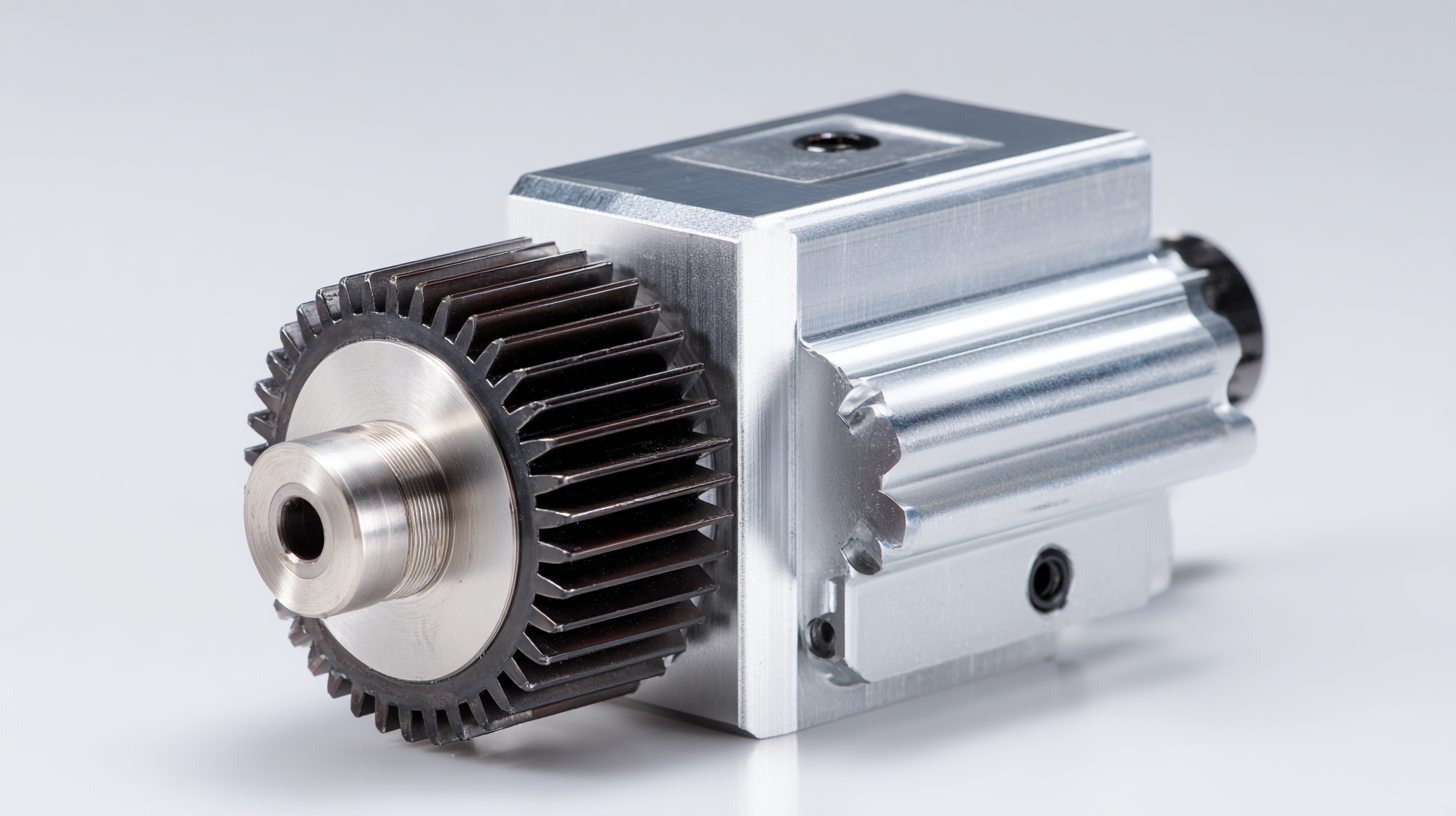

Worm gear reducers are essential components in a variety of modern machinery applications due to their unique design and functionality. These reducers consist of a worm (a screw-like gear) and a worm wheel (a gear that meshes with the worm). This configuration allows for significant speed reduction, which is crucial in machinery that requires lower speeds but higher torque. Additionally, the design inherently provides a high level of mechanical advantage while ensuring compact sizing, making worm gear reducers ideal for space-constrained applications.

One of the primary benefits of using worm gear reducers is their ability to offer self-locking properties. This feature prevents reverse motion, making them particularly valuable in applications where load holding is critical, such as elevators and conveyors. Moreover, the smooth operation of worm gears minimizes noise and vibration, contributing to overall machine efficiency and longevity. As industries continue to evolve, the versatility and efficiency of worm gear reducers make them a key component in enhancing the performance of modern machinery.

Efficiency and Performance: The Benefits of Using Worm Gear Reducers

Worm gear reducers have gained popularity in modern machinery applications due to their remarkable efficiency and performance. One of the primary advantages of these reducers is their ability to provide a high torque output while maintaining a compact size. The unique design of worm gears allows for significant gear reduction in a relatively small configuration, making them ideal for space-constrained environments. This compactness does not come at the expense of performance; on the contrary, worm gear reducers often exhibit low backlash and smooth operation, which enhances the precision and reliability of machinery.

Another key benefit of using worm gear reducers is their inherent self-locking mechanism. This feature prevents reverse motion and holds loads securely, adding an extra layer of safety in applications such as conveyor systems and elevators. Additionally, worm gears are compatible with various lubricants, which can enhance their lifespan and reduce maintenance requirements. Overall, the combination of high efficiency, excellent torque characteristics, and self-locking capabilities makes worm gear reducers an essential component in a diverse range of modern machinery settings.

Applications of Worm Gear Reducers in Various Industries

Worm gear reducers are widely used across various industries due to their unique ability to provide high torque and compact design. In manufacturing, these reducers play a critical role in conveyor systems, allowing for smooth and efficient movement of materials. Their self-locking feature prevents back-driving, making them ideal for applications where safety and reliability are paramount, such as in escalators and lifting equipment.

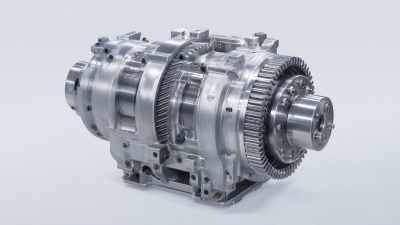

In the automotive and aerospace industries, worm gear reducers contribute to precision and performance in steering mechanisms and landing gear systems. Their design minimizes wear and tear, helping reduce maintenance costs and downtime. This makes them an excellent choice for applications requiring consistent reliability and longevity over time.

**Tips:** When selecting a worm gear reducer, consider factors such as load demand, operating conditions, and efficiency requirements. Ensure proper alignment during installation to maximize performance and lifespan. Regular maintenance checks can also help identify wear patterns early, allowing for timely interventions that prevent costly failures.

Comparative Analysis: Worm Gear Reducers vs. Other Gear Types

Worm gear reducers offer several advantages when compared to other gear types, particularly in applications requiring high torque and compact design. Unlike bevel or helical gears, worm gears provide a significant gear reduction in a smaller footprint, making them ideal for applications where space is a constraint. They operate with a unique sliding contact, which reduces wear and tear while offering quieter operation. This feature is particularly beneficial in settings where noise reduction is critical, such as in medical equipment or robotics.

Worm gear reducers offer several advantages when compared to other gear types, particularly in applications requiring high torque and compact design. Unlike bevel or helical gears, worm gears provide a significant gear reduction in a smaller footprint, making them ideal for applications where space is a constraint. They operate with a unique sliding contact, which reduces wear and tear while offering quieter operation. This feature is particularly beneficial in settings where noise reduction is critical, such as in medical equipment or robotics.

Furthermore, the self-locking nature of worm gears provides a significant safety benefit. In contrast to spur gears or planetary gears, which can backdrive under certain conditions, worm gear reducers prevent reverse motion, enhancing the reliability of machinery in use. The flow of power is directed in one way, ensuring that systems remain stable and secure during operation. This characteristic makes worm gears indispensable in elevators, conveyors, and other heavy machinery. Overall, the comparative analysis indicates that worm gear reducers are particularly suited for specialized applications where reliability, size, and noise reduction are paramount.

Maintenance and Longevity: Best Practices for Worm Gear Reducers

Worm gear reducers are increasingly being employed in modern machinery applications due to their unique advantages, such as high torque and compact design. However, to ensure their optimal performance and longevity, proper maintenance practices are essential. Regular inspections and proactive maintenance routines can greatly enhance the lifespan of these critical components. For instance, ensuring that the gearboxes are lubricated according to the manufacturer's specifications can prevent unnecessary wear and overheating, which are common causes of failure.

In applications where multiple worm reducers are used, such as in welded mills, it is crucial to monitor the alignment and operation of the entire drive system. Even minor misalignments can lead to increased stress on the reducers, reducing their efficiency and lifespan. Additionally, implementing a routine for cleaning and checking for signs of contamination can significantly mitigate operational risks. By adhering to these best practices, operators can effectively prolong the life and reliability of worm gear reducers, ultimately leading to greater productivity and reduced downtimes in various machinery applications.

Exploring the Advantages of Worm Gear Reducers in Modern Machinery Applications - Maintenance and Longevity: Best Practices for Worm Gear Reducers

| Dimension |

Specification |

Benefit |

Maintenance Frequency |

Expected Longevity |

| Gear Ratio |

5:1 - 100:1 |

High torque output |

Annually |

10-15 years |

| Efficiency |

85% - 95% |

Low energy loss |

Biannually |

15-20 years |

| Operating Temperature |

-20°C to 100°C |

Versatile application |

As needed |

Up to 25 years |

| Material |

Aluminum / Steel |

Corrosion resistant |

Every 2 years |

15-25 years |

| Backlash |

Low (1-2 degrees) |

Precision motion control |

Annually |

20-30 years |

Worm gear reducers offer several advantages when compared to other gear types, particularly in applications requiring high torque and compact design. Unlike bevel or helical gears, worm gears provide a significant gear reduction in a smaller footprint, making them ideal for applications where space is a constraint. They operate with a unique sliding contact, which reduces wear and tear while offering quieter operation. This feature is particularly beneficial in settings where noise reduction is critical, such as in medical equipment or robotics.

Worm gear reducers offer several advantages when compared to other gear types, particularly in applications requiring high torque and compact design. Unlike bevel or helical gears, worm gears provide a significant gear reduction in a smaller footprint, making them ideal for applications where space is a constraint. They operate with a unique sliding contact, which reduces wear and tear while offering quieter operation. This feature is particularly beneficial in settings where noise reduction is critical, such as in medical equipment or robotics.